Patents

Literature

41results about How to "Increase color variety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrahigh-weather-resistance PVC (polyvinyl chloride) coextruded surface material and manufacturing method thereof

ActiveCN104893143AHigh surface hardnessIncrease temperatureWeather resistanceChlorinated polyvinyl chloride

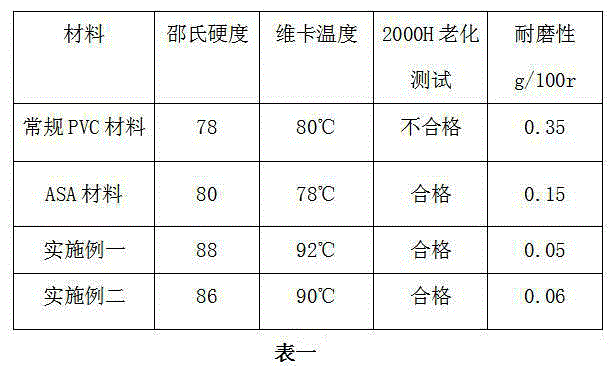

The invention an ultrahigh-weather-resistance PVC (polyvinyl chloride) coextruded surface material and a manufacturing method thereof, belonging to the field of composite materials. The ultrahigh-weather-resistance PVC coextruded surface material comprises the following components in parts by mass: 40-60 parts of PVC powder, 20-50 parts of CPVC (chlorinated polyvinyl chloride), 10-20 parts of calcium carbonate powder, 0.4-6 parts of stabilizer, 4-7 parts of impact modifier, 1-3 parts of lubricant, 0.4-0.9 part of anti-ultraviolet agent, 0.4-0.9 part of antioxidant, 0.5-1 part of antistatic agent, 3-6 parts of whisker and 3-6 parts of toner. By adjusting the formula, the material has comparable weather resistance with ASA (acrylonitrile-styrene-acrylate), and has higher surface hardness and Vicat softening point temperature. The material is low in cost, does not need to depend on import, and can obviously lower the production cost. The production cost of the product is only about one half of that of the ASA material. The product can be widely used in surface coextrusion of PVC door / window profiles, PVC wood-plastic profiles and PVC tiles to enhance the physical properties and colorfulness of the product.

Owner:DONGGUAN BETTO WOOD NEW MATERIAL TECH CO LTD

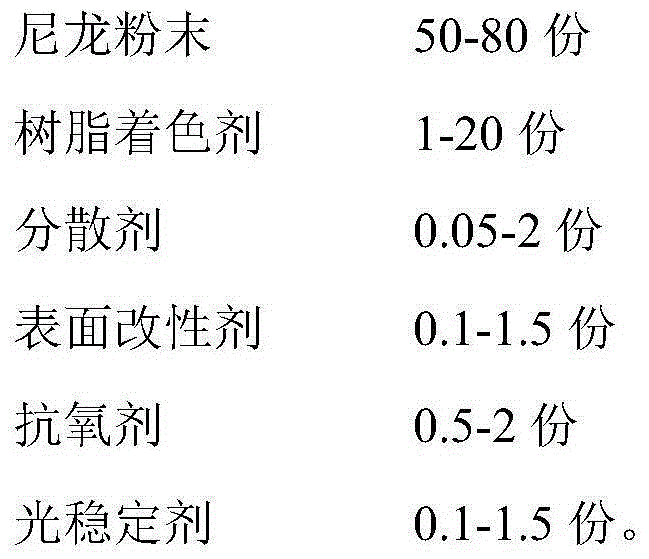

Nylon powder material for selective laser sintering and preparation method of nylon power material

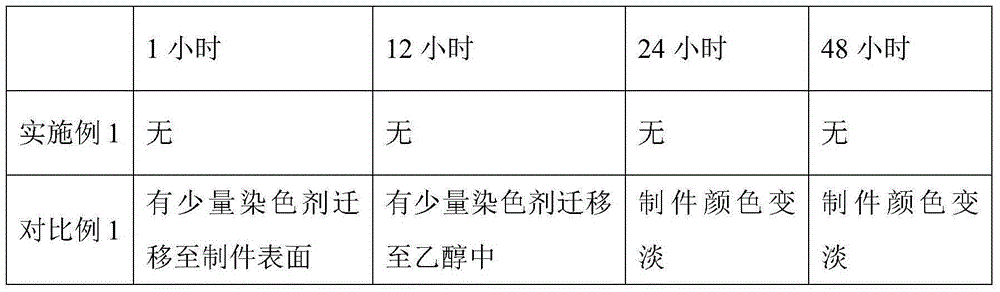

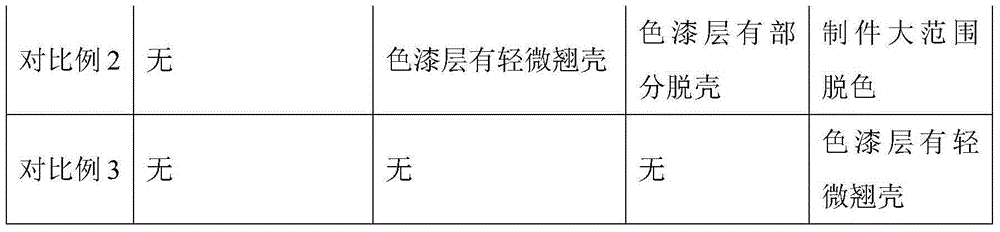

The invention provides a nylon powder material for selective laser sintering and a preparation method of the nylon power material. The nylon powder material is prepared from, by weight, 50-80 parts of nylon powder, 1-20 parts of resin coloring agents, 0.05-2 parts of dispersing agents, 0.1-1.5 part of surface modification agents, 0.5-2 parts of antioxidants and 0.1-1.5 parts of light stabilizers. The nylon powder material for selective laser sintering is colored. The colored nylon powder material can directly form 3D printed products uniform in luster and different in color through the SLS technology under the condition that the printed products do not need to be post-processed, and different requirements of clients in various fields for product colors can be met.

Owner:SHENZHEN SUNSHINE LASER & ELECTRONICS TECH CO LTD

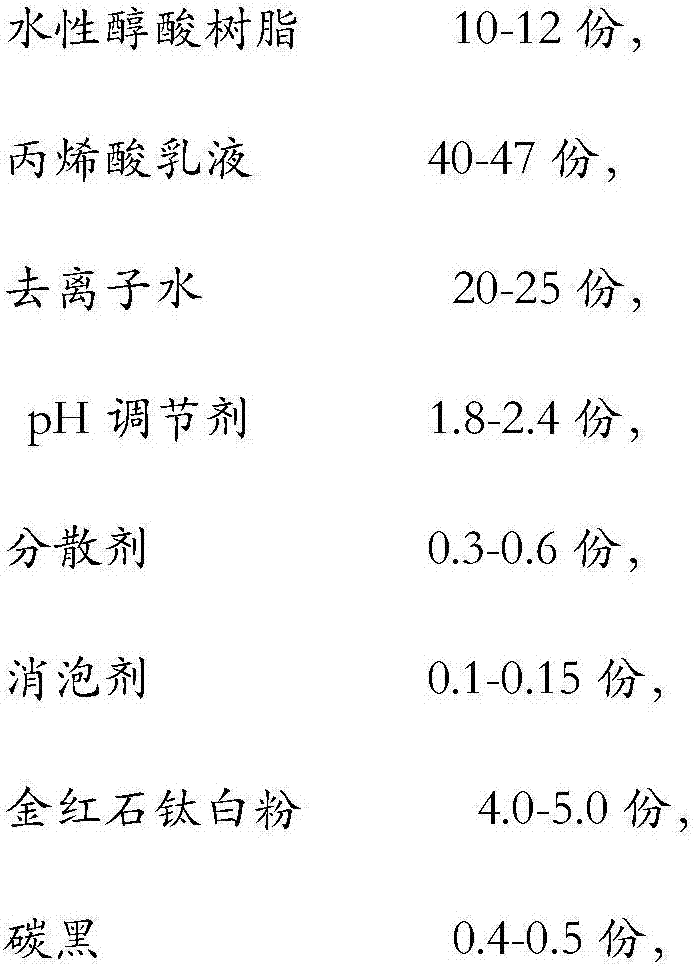

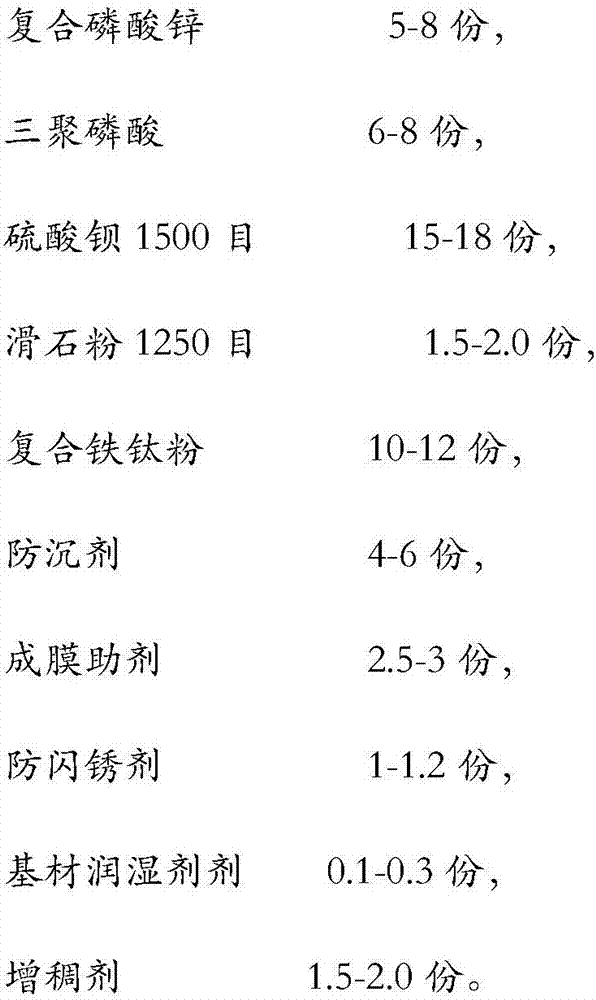

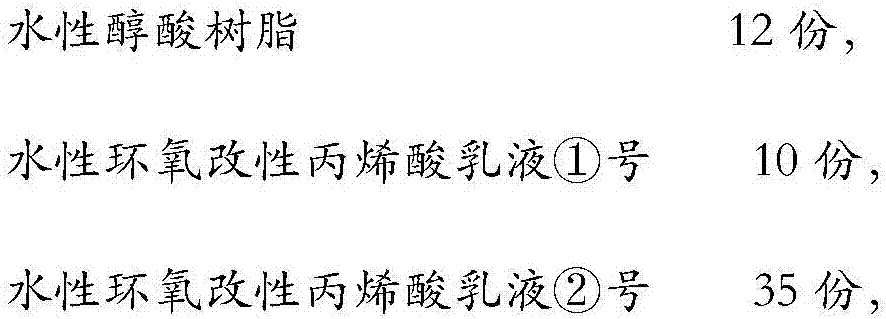

Environment-friendly water-based acrylic acid modified alkyd protective paint used for spraying mechanical equipment, and preparation method of protective paint

InactiveCN106928791AValid setLow VOC contentAnti-corrosive paintsPolyester coatingsWater basedMechanical equipment

The invention discloses environment-friendly water-based acrylic acid modified alkyd protective paint used for spraying mechanical equipment, and a preparation method of the protective paint. The environment-friendly water-based acrylic acid modified alkyd protective paint used for spraying the mechanical equipment comprises the following components in parts by weight: 10-12 parts of water-based alkyd resin, 40-47 parts of acrylic emulsion,20-25 parts of water, 1.8-2.4 parts of a pH (potential of hydrogen) regulator, 0.3-0.6 parts of a dispersant, 0.1-0.15 parts of a defoaming agent, 4.0-5.0 parts of rutile titanium dioxide, 0.4-0.5 parts of carbon black, 5-8 parts of compound zinc phosphate, triphosphoric acid, barium sulfate, talcum powder, iron-titanium compound powder, an anti-settling agent, a film forming assistant, a flash-rust preventive, a base material wetting agent and a thickening agent. The protective paint has excellent chemical properties such as corrosion resistance and water resistance, and is high in drying rate, excellent in low-temperature film forming effect, high in plumpness and good in weather resistance.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

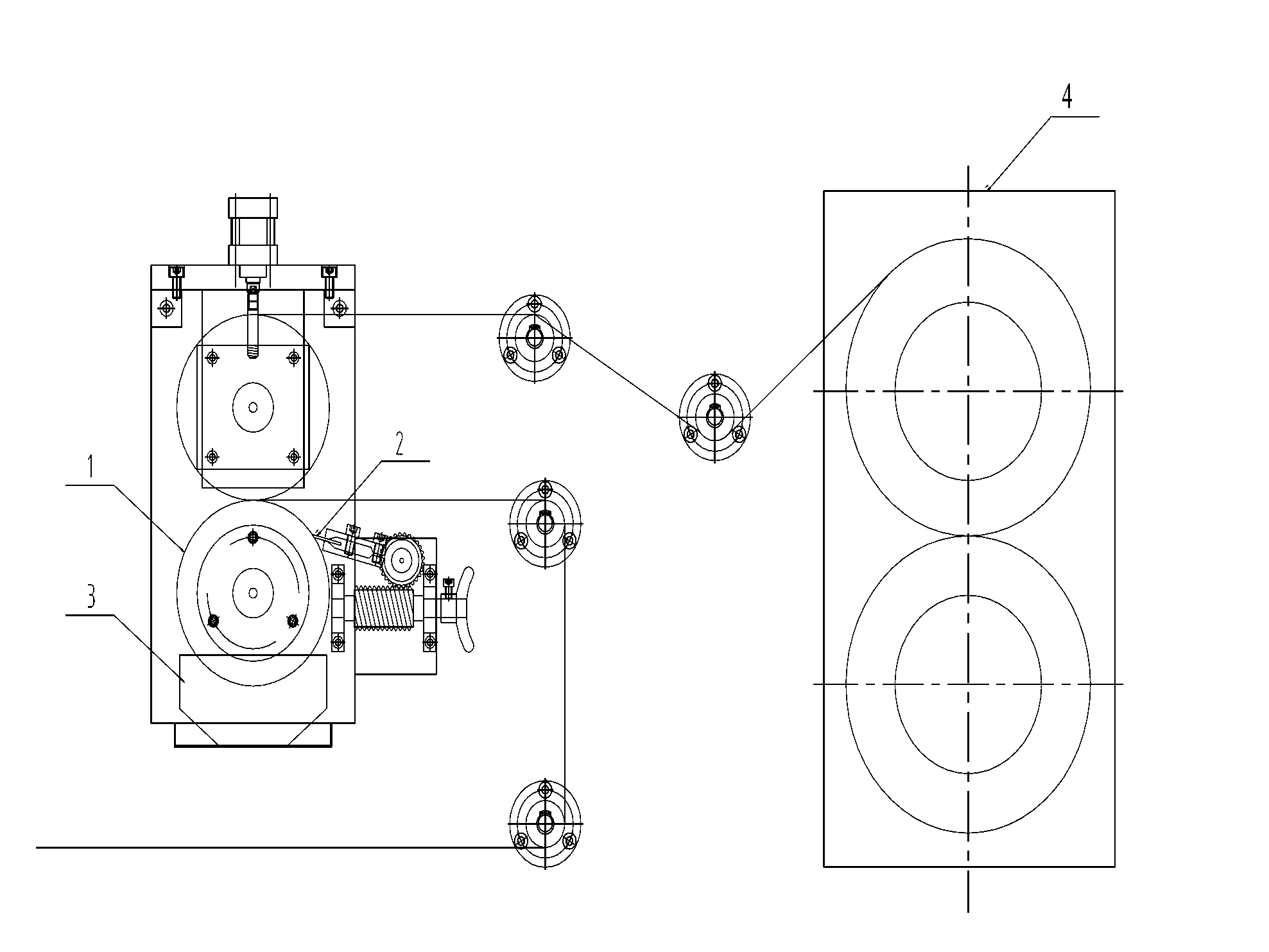

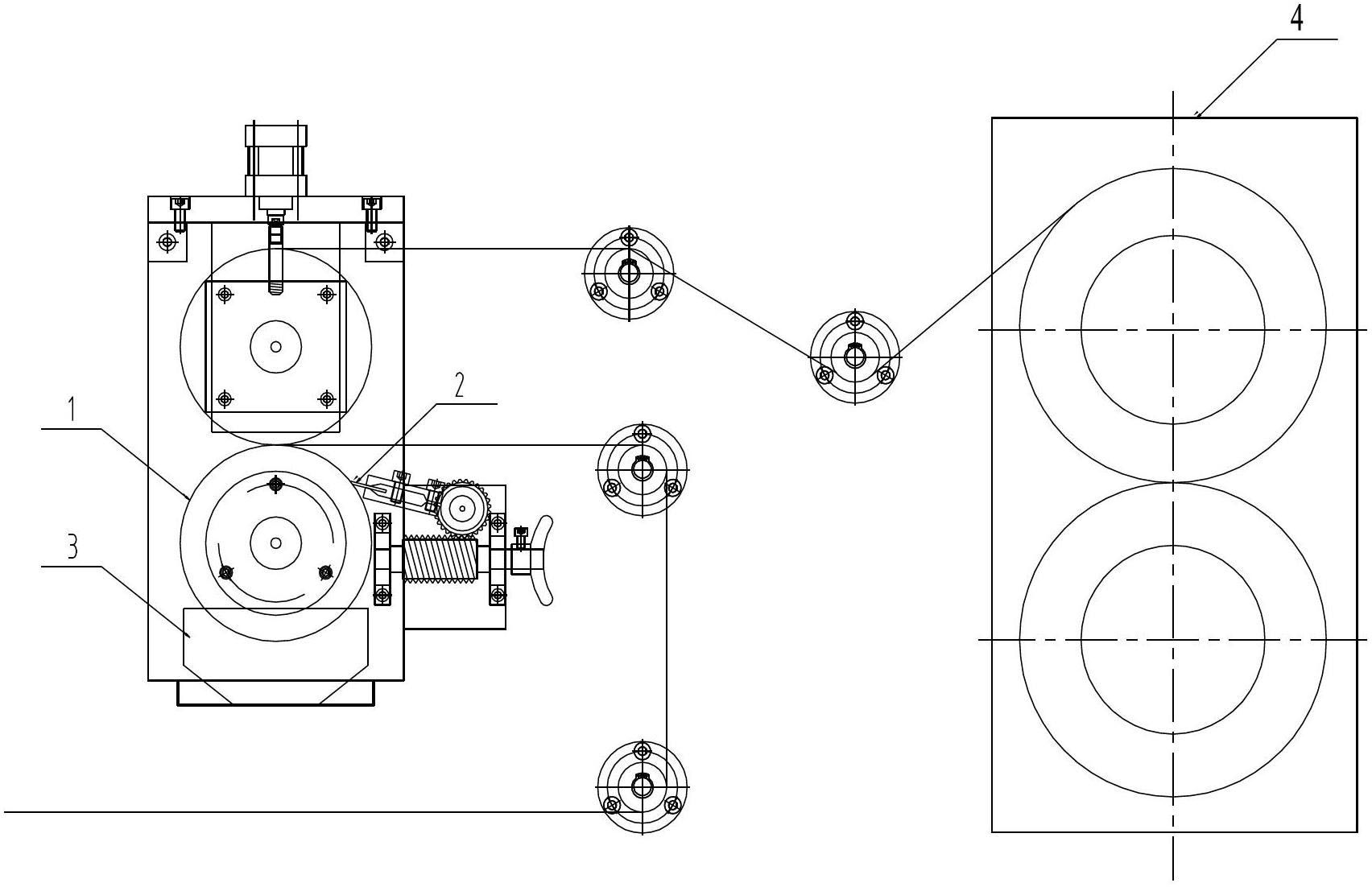

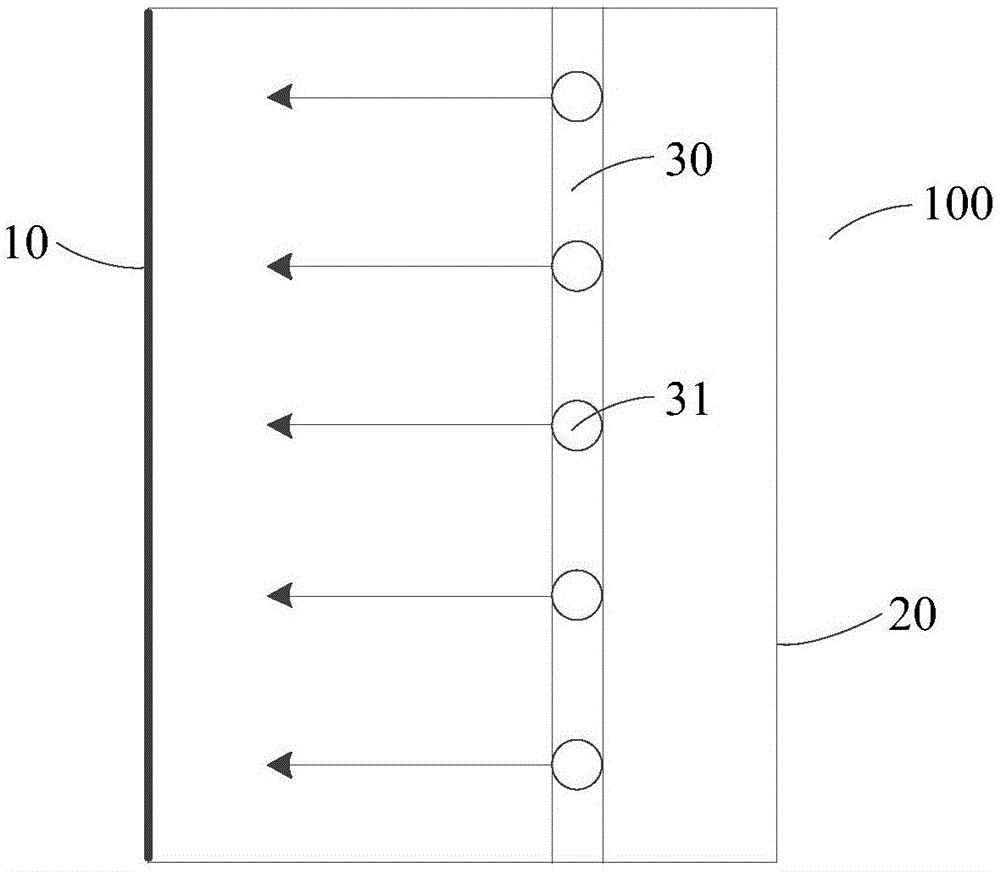

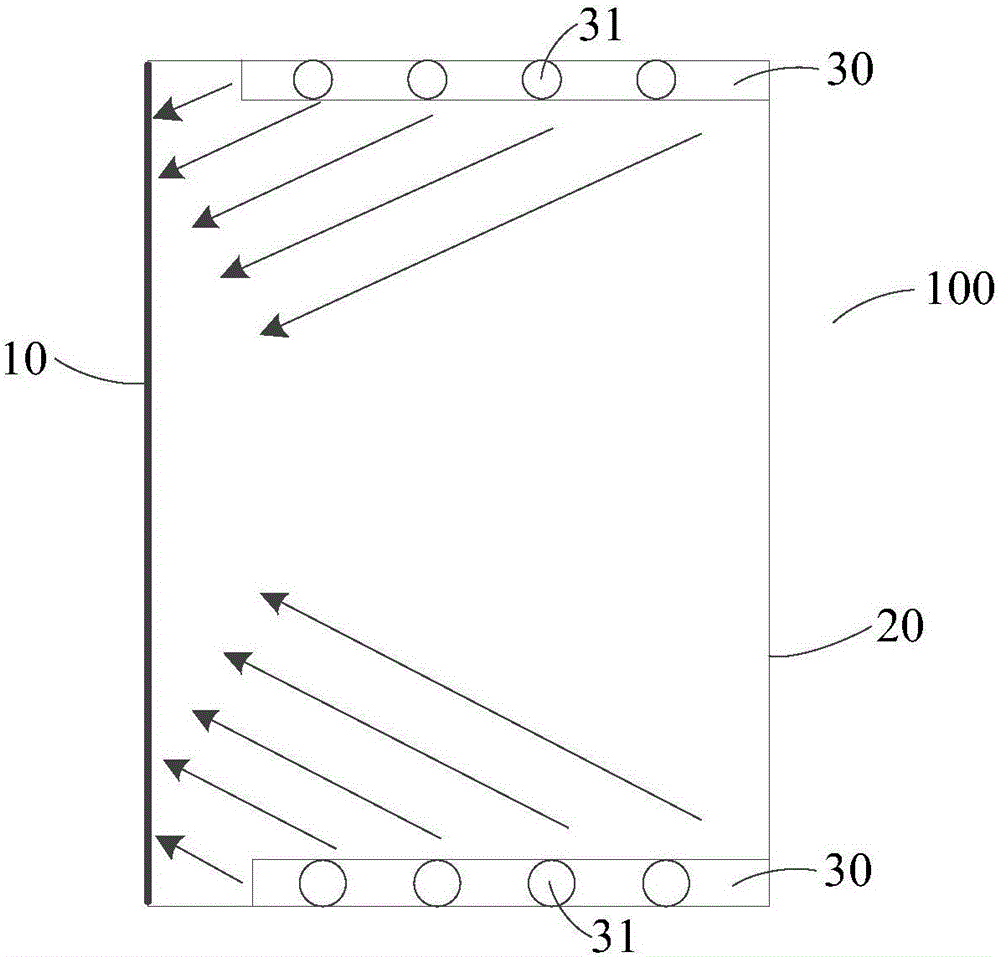

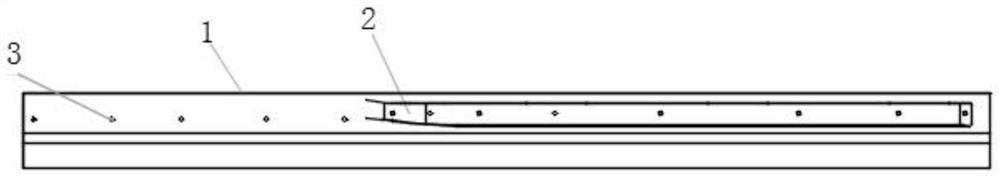

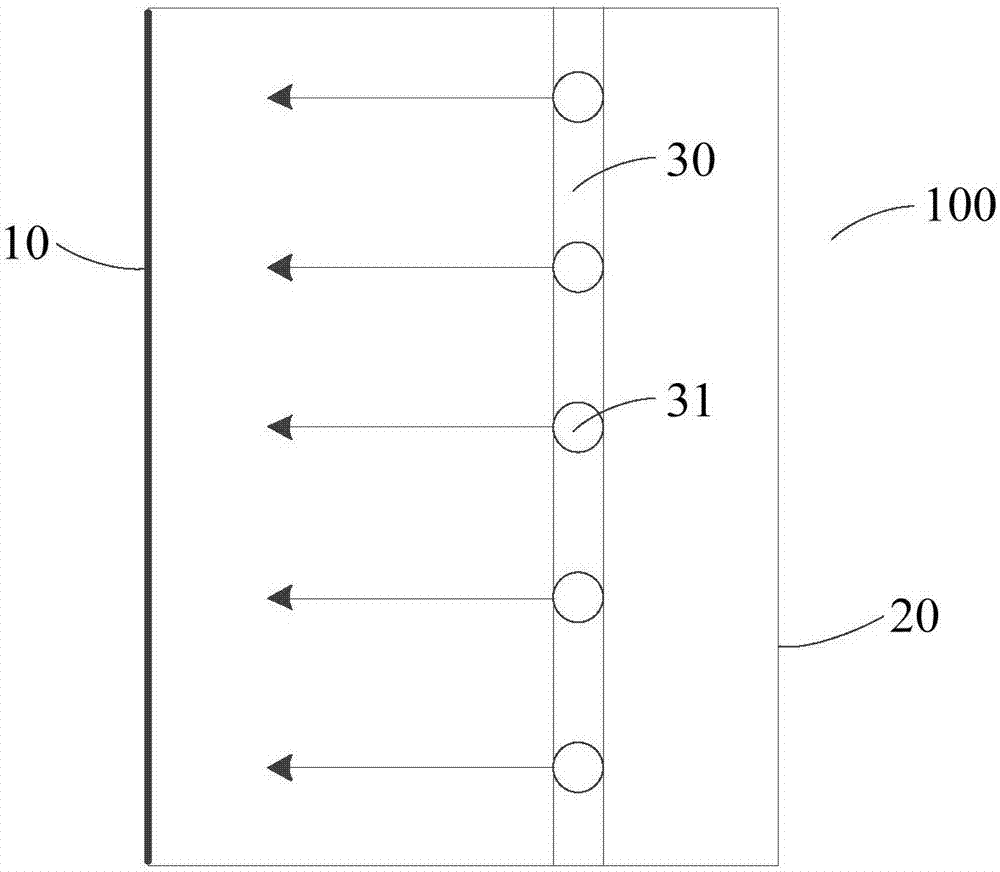

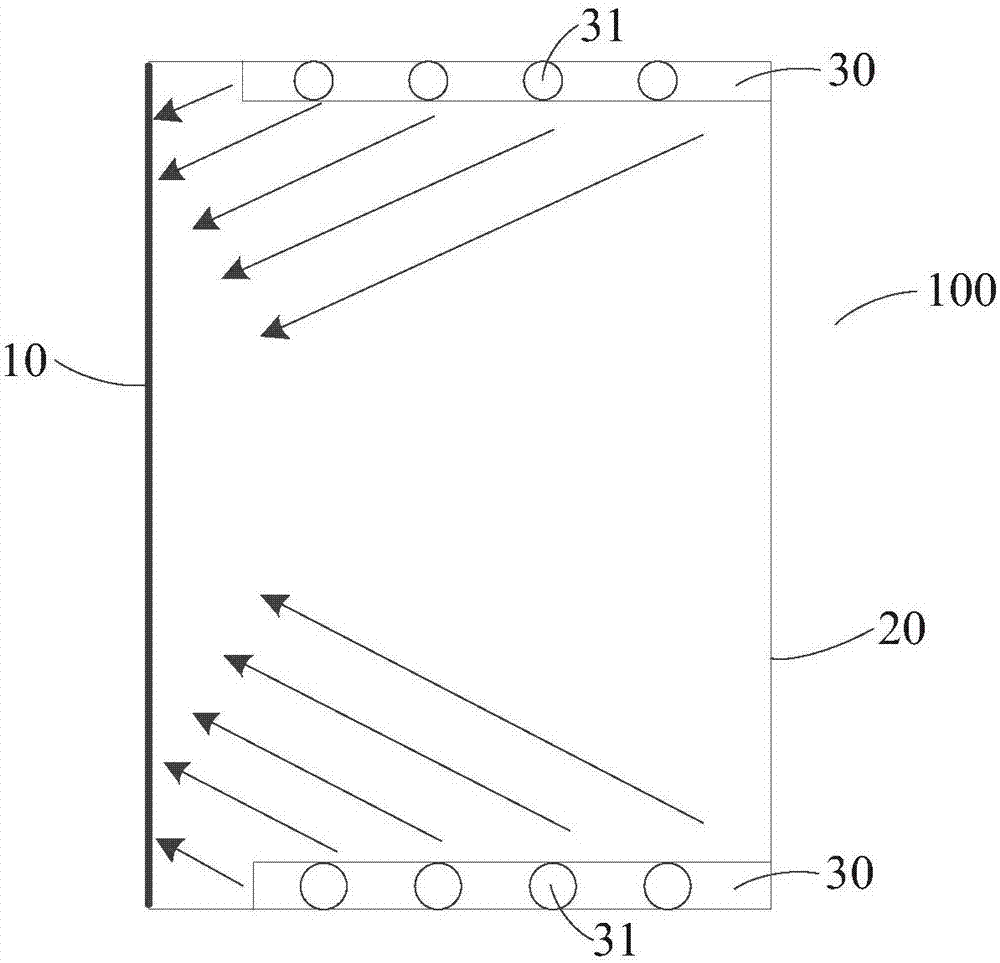

Printed non-woven fabric and manufacturing device

InactiveCN102704191AChange appearanceIncrease color varietyRotary intaglio printing pressNon-woven fabricsEngineeringDesign methods

The invention discloses printed air-thermal-bonded non-woven fabric which is mainly used for the surface or the second-layer material of a personal sanitary nursing article. According to the printed air-thermal-bonded non-woven fabric, printing is carried out by adopting an ink transferring technology on the basis of air-thermal-bonded non-woven fabric, which has the advantages that the problems that the existing air-thermal-bonded non-woven fabric is single in design and color and difficult to print are solved, the appearance attractiveness of the sanitary article is enhanced, and the aesthetic fatigue of a consumer during use is reduced. The design method is novel and available for effectively improving the appearance of the air-thermal-bonded non-woven fabric.

Owner:北京大源非织造股份有限公司

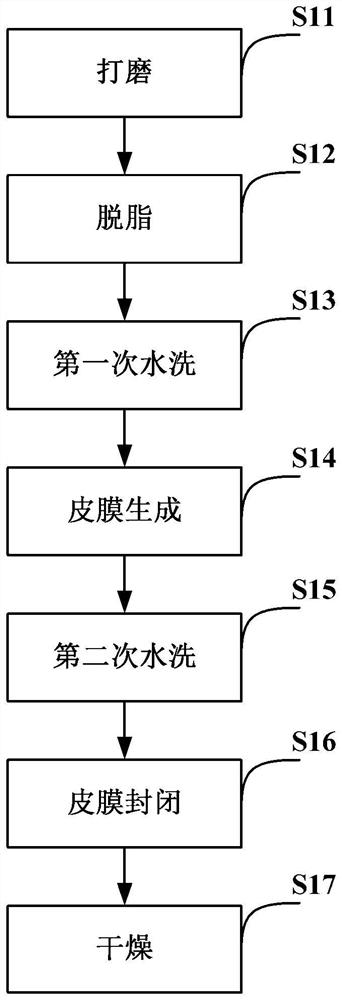

Magnesium alloy section bar electrostatic powder spraying production method

InactiveCN101632983AIncrease color varietyColor variety achievedPretreated surfacesCoatingsProduction lineNonferrous metal

The invention relates to a magnesium alloy section bar electrostatic powder spraying production method which belongs to the technical field of surface processing of nonferrous metal. The method is characterized by comprising the following technical steps: soaking a magnesium alloy section bar in a nitric acid solution at normal temperature to carry out degreasing processing, and washing the magnesium alloy section bar after degreasing processing by running water till the nitric acid solution on a workpiece is completely removed; drying the washed magnesium alloy section bar; after the magnesium alloy section bar is dried, loading on the horizontal type spray production line and spraying powder on the magnesium alloy section bar by a spray gun; and curing the sprayed magnesium alloy section bar into a finished product. The invention can meet the requirement of a customer and vary colors of the magnesium alloy section bar, and the adhesive force reaches the zero grade according to a grid test of GB / T9286; the detection of indentation hardness is carried out according to GB / T9275 and is larger than or equal to 80; other properties conform to the standard of GB5237; and the invention can improve the corrosion resistance and the hardness of the magnesium alloy section bar and vary the colors of the magnesium alloy section bar.

Owner:江苏锦绣铝业有限公司

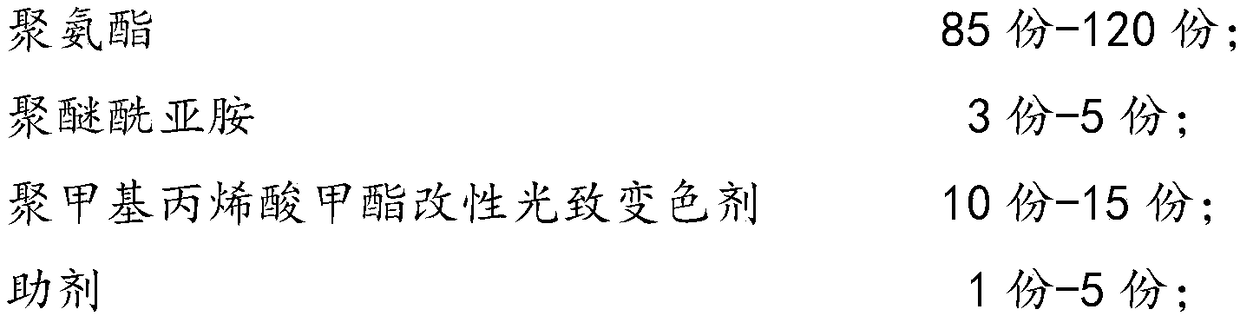

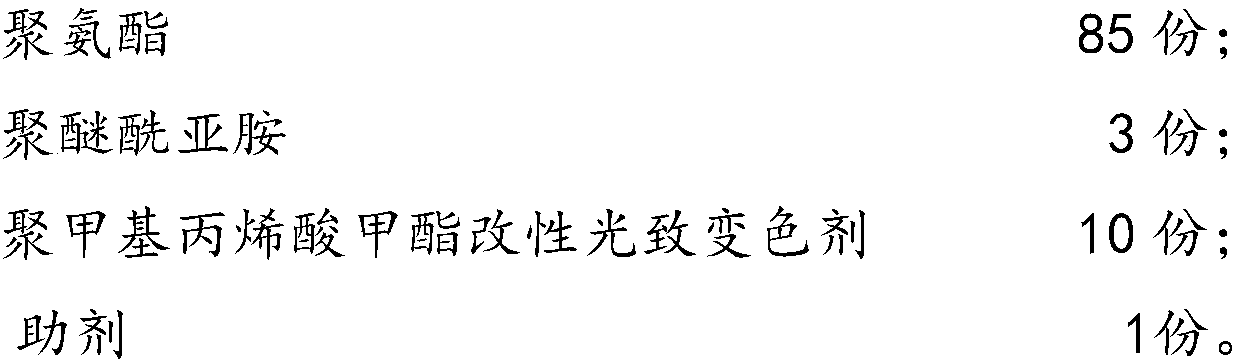

Photochromic polyurethane composite with ultraviolet-resistant function

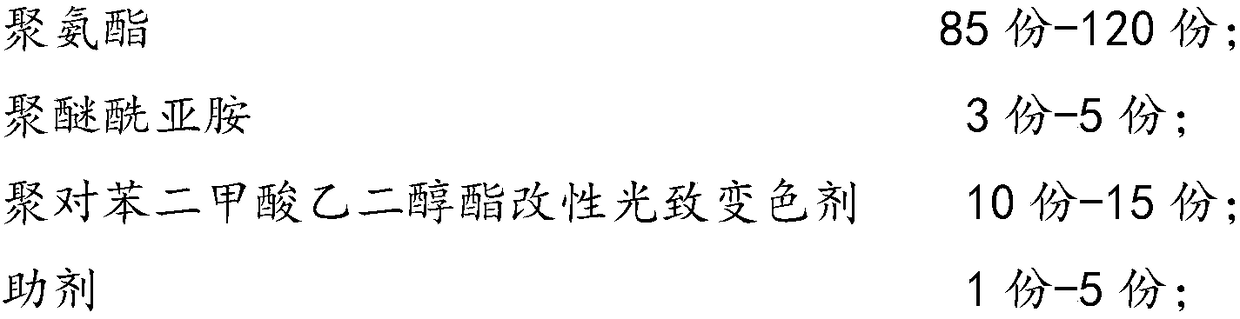

InactiveCN109370561AIncrease color varietyAchieving uniformity of distributionTenebresent compositionsPolyetherimideUltraviolet

The invention relates to a photochromic polyurethane composite with an ultraviolet-resistant function. The photochromic polyurethane composite comprises the components in parts by weight: 85-120 partsof polyurethane, 3-5 parts of polyetherimide, 10-15 parts of polymethyl methacrylate modified photochromic agent and 1-5 parts of auxiliaries; and the photochromic agent comprises an inorganic photochromic agent and an organic photochromic agent. In the technical scheme, the polymethyl methacrylate modified photochromic agent is added into polyurethane, the distribution uniformity of a photochromic material in polyurethane is realized due to the coating of polymethyl methacrylate, in addition, the organic photochromic agent is changed into different colors according to different rays, so thatthe use range of polyurethane is widened.

Owner:RUGAO FUDA ENG & TECH RES INST CO LTD

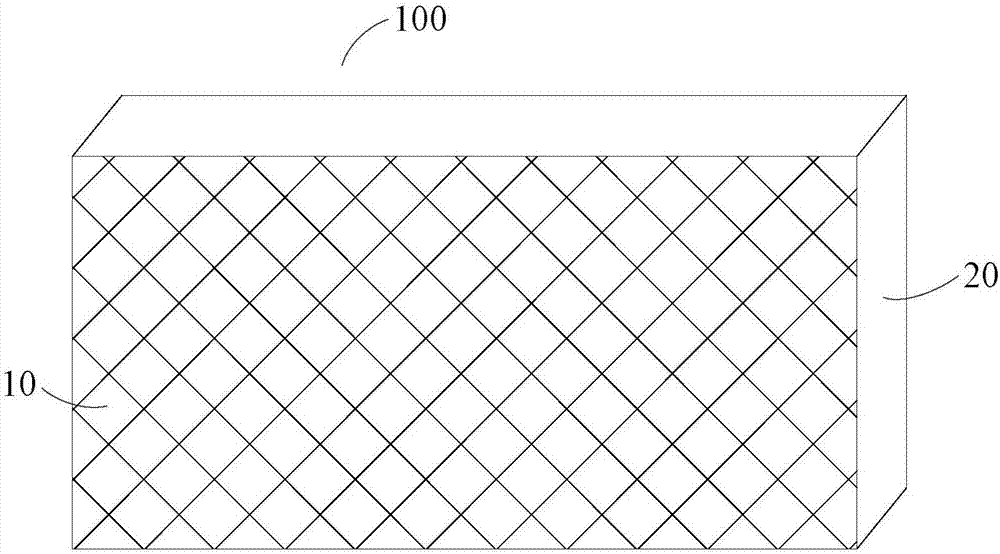

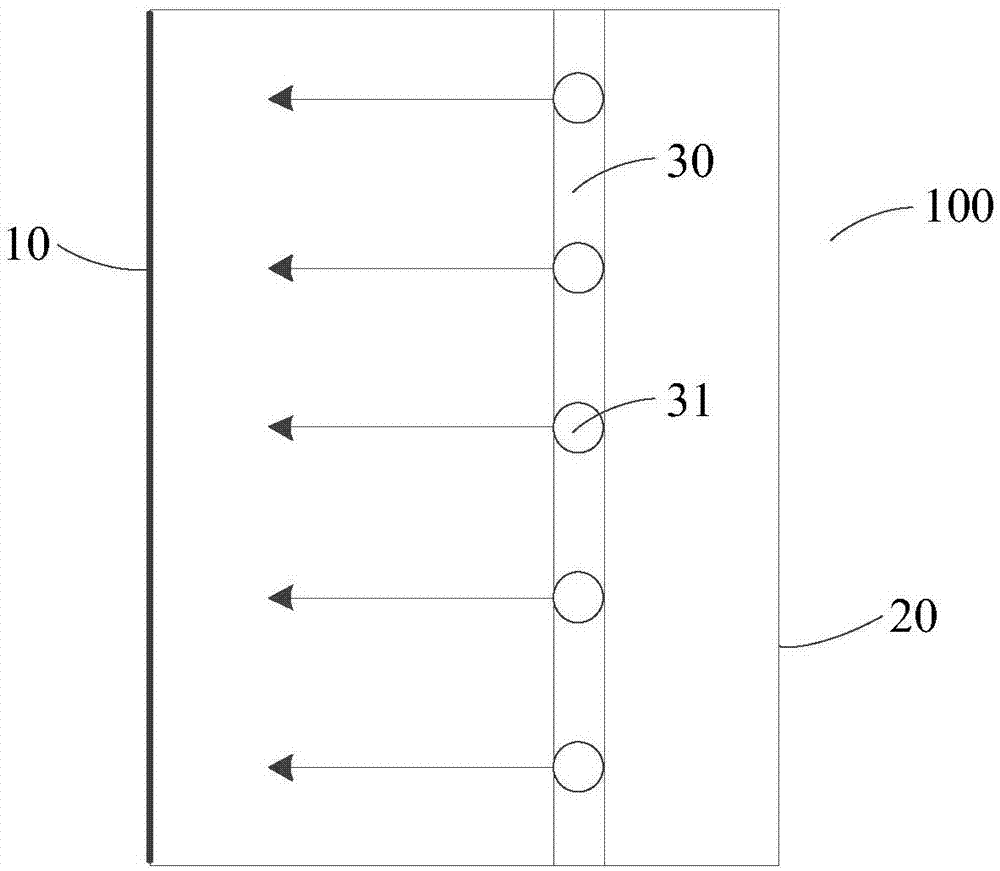

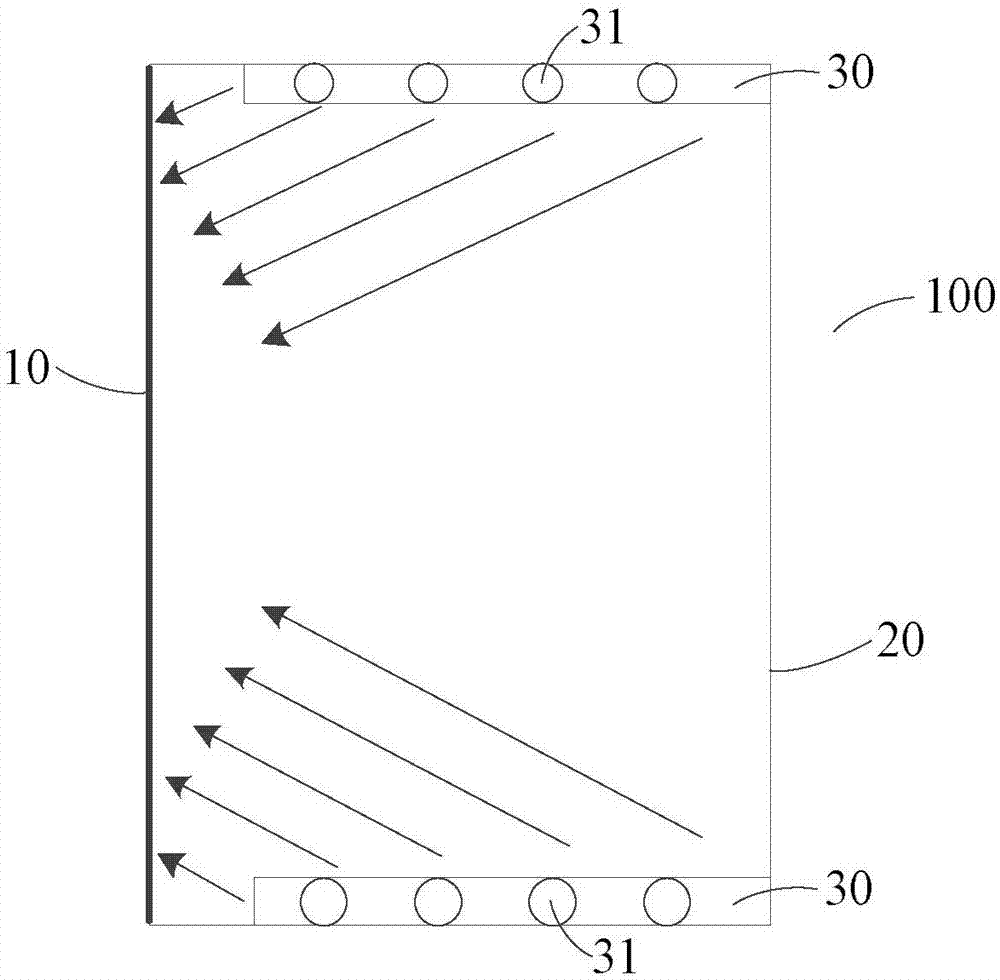

Lamp box cloth and lamp box

ActiveCN107263981AIncrease color varietyEffective coolingSynthetic resin layered productsOptical articlesQuantum dotQuantum

The embodiment of the invention provides lamp box cloth and a lamp box, the lamp box cloth includes a reflection layer and a substrate layer, the reflection layer is arranged on the one side of the substrate layer, the reflection layer comprises a metal material, when visible light is reflected by the reflection layer, the surface of the lamp box cloth shows at least metal luster, a plurality of grooves are arranged on the substrate layer at intervals, and quantum dots are arranged and packed in the grooves. The reflection layer is arranged in the lamp box cloth, so that the lamp box cloth can reflect external light, and the surface of the lamp box cloth shows the metal luster, when the lamp box cloth is observed from different external angles, a gradient color effect can be shown by the lamp box cloth, the color diversity of the lamp box can be enhanced; in addition, due to the arrangement of the quantum dots, purposes of effective heat dissipation and wide color gamut can be achieved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

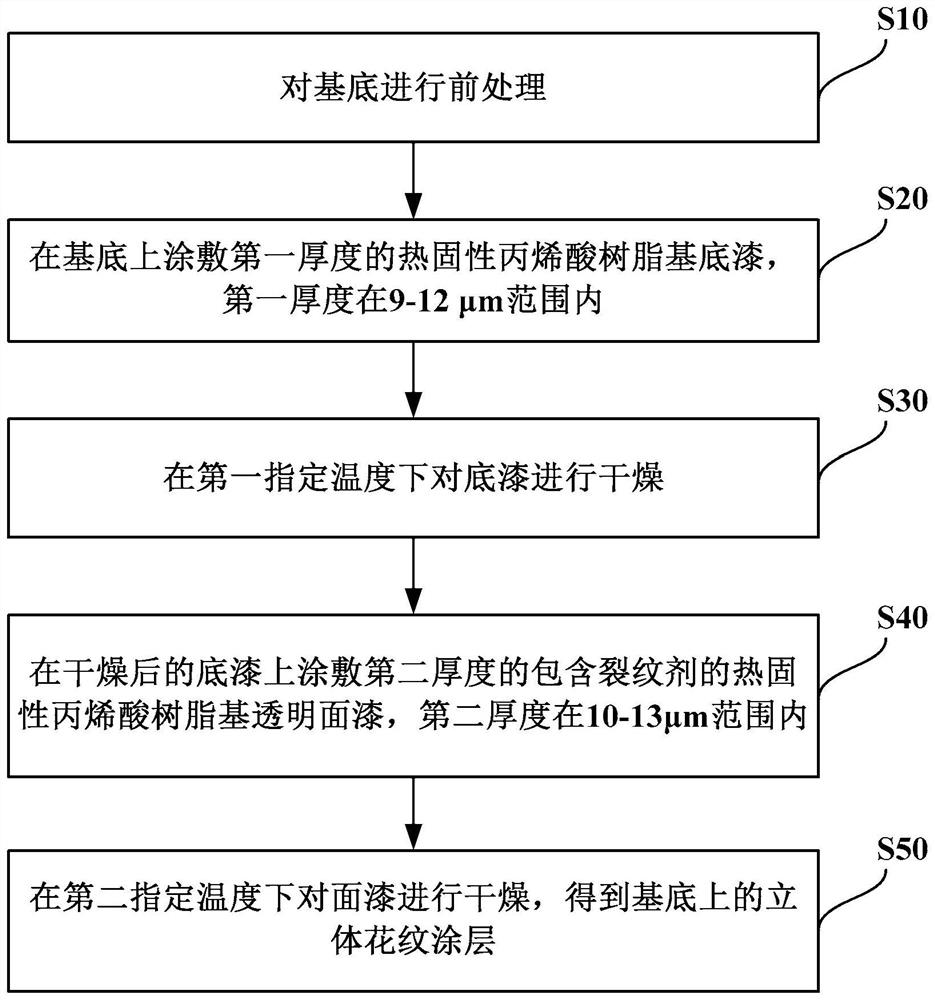

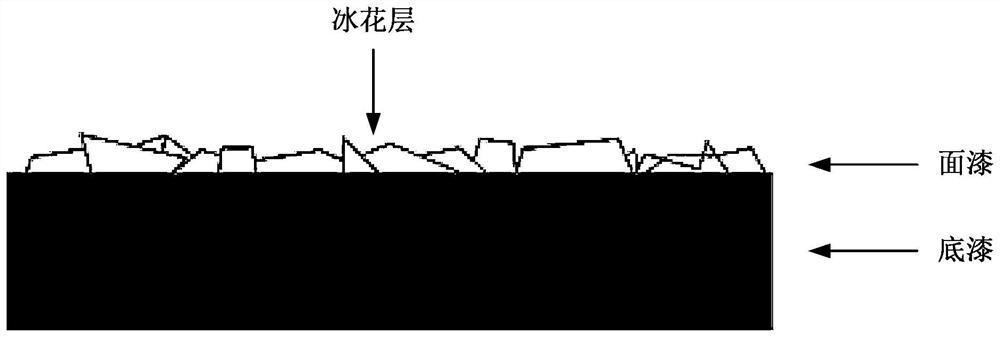

Three-dimensional pattern coating and preparation method thereof, lamp accessory and lamp

InactiveCN111992469AWith three-dimensional effectSimple processLighting elementsProtective devices for lightingPolymer scienceCrazing

The invention provides a preparation method for a three-dimensional pattern coating, the three-dimensional pattern coating, a lamp accessory and a lamp. The preparation method comprises the followingsteps: carrying out pretreatment on a substrate; coating the substrate with a thermosetting acrylic resin-based primer with a first thickness, wherein the first thickness is in a range of 9-12 micrometers; drying the primer at a first specified temperature; coating the dried primer with thermosetting acrylic resin-based transparent finish paint with a second thickness which contains a cracking agent, wherein the second thickness is in a range of 10-13 micrometers; and drying the finish paint at a second specified temperature to obtain the three-dimensional pattern coating on the substrate. Thedifference of the shrinkage rates of the priming paint with specific thickness and the finishing paint with specific thickness is utilized, a cracking agent is used for assistance, so that the finishing paint is cracked to form the texture similar to ice patterns, and the three-dimensional pattern coating is obtained. The coating is unique in pattern and has a three-dimensional effect. In addition, the preparation method is simple in process and wide in application range.

Owner:SUZHOU OPPLE LIGHTING +1

Portable illuminating lamp

InactiveCN106195709AEasy to expandStable supportLighting support devicesWith electric batteriesEngineeringLED lamp

The invention relates to a portable illuminating lamp. The portable illuminating lamp comprises a communication body, an LED lamp panel and a supporting rubber sleeve; the communication body is provided with a display screen; the LED lamp panel is arranged on the side, deviating from the display screen, of the communication body and is provided with a plurality of LED lamp beads; the supporting rubber sleeve is attached to the LED lamp panel and comprises two telescopic rubber plates; one end of each telescopic rubber plate is rotationally arranged on the middle portion of the LED lamp panel; the communication body is provided with a decoration assembly; the decoration assembly comprises a rotating shaft and a plurality of decoration wafers detachably arranged on the rotating shaft; and the colors of the multiple decoration wafers are set different. The portable illuminating lamp is convenient to carry, the light rays emergent out of the LED lamp panel can form lamplight in different colors, and color diversity of light outgoing is improved.

Owner:东莞市闻誉实业有限公司

Technological method of preparation of low-temperature curing heavy-duty epoxy powder coating

InactiveCN106634399AShort manufacturing timeImprove matt propertiesAnti-corrosive paintsPowdery paintsEpoxyPolypropylene

The invention discloses a technological method of preparation of a low-temperature curing heavy-duty epoxy powder coating, and the technological method comprises the following steps: A, pulverizing epoxy resin into a fine-particle powder by using a pulverizing apparatus, and then adding other auxiliaries; B, mixing the epoxy resin powder and the auxiliaries, and performing uniform stirring; C, putting the uniformly-stirred mixture in a heating and pressurizing apparatus with the temperature of 100-103 DEG C, and performing heating and pressurizing, so as to obtain a semi-finished product, wherein the time of the heating and pressurizing process is not less than 20 minutes, and the obtained semi-finished product is flaky; D, pulverizing the flaky semi-finished product obtained in the step C, and then adding a polypropylene filler with the weight ratio of 2-3% and a pigment with the weight ratio of 3-5% after pulverization; E, stirring the mixture obtained in the step D and sieving the mixture with a sieve; and F, checking the sieved epoxy-powder coating, and performing packaging. The technological method enriches the application fields of the epoxy powder coating, saves the processes of the later-stage use of the epoxy powder coating, and guarantees relatively good application performance of the epoxy powder coating.

Owner:丹阳市海信涂料化工厂

Method for preparing functional highly-twisted color dot yarn

InactiveCN108716042ASimple designStrong three-dimensional senseArtificial filaments from cellulose solutionsDyeing processYarnFiber

The invention discloses a method for preparing functional highly-twisted color dot yarn. The color dot yarn prepared by means of the method is formed through the steps that color fibers are intermittently implanted in the process of twisting filaments, discontinuous color dots are formed on the surfaces of the filaments, and the thickness and length of the color dots can be controlled. The color dot yarn has more changes in the color of the yarn, the three-dimensional feeling of the yarn is stronger, more changes are provided for the style of fabric, the variety of the filaments is enriched, and the progress and development of a filament technology are promoted. In the prepared color dot yarn, copper ammonia fiber filaments and ultra-high molecular weight polyethylene fiber filaments adopted as the filaments, and after being highly twisted, the filaments have the performance of cooling, air permeability, moisture absorption, high strength, wear resistance and the like; in the twistingprocess, luminous fiber color dots with two colors are added, the luminous fibers can emit light in the daytime and at night, different colors are presented, and the color richness and three-dimensional feeling of the highly-twisted yarn are improved; by means of the method, the application of the functional fibers is promoted, and the design of textile products is enriched.

Owner:IANGSU COLLEGE OF ENG & TECH

Production process of moisture-absorbing, sweat-releasing and antibacterial colored textile fabric

ActiveCN113265742AAdds antimicrobial and color richnessImproves strength and spinnabilityWoven fabricsPolyesterWeft yarn

The invention discloses a production process of a moisture-absorbing, sweat-releasing and antibacterial colored textile fabric. The production process comprises the following steps of S1, adding a coloring agent and antibacterial particles into a spinning solution of polyester fibers to prepare modified antibacterial polyester fibers; S2, blending the modified antibacterial polyester fibers with other fibers to prepare blended yarns a and blended yarns b; S3, enabling the blended yarns a to be subjected to yarn doubling treatment, and obtaining double-strand warp yarns; S4, enabling the blended yarns b and spandex to be subjected to core-spun treatment, and preparing weft yarns; and S5, weaving the warp yarns and the weft yarns to obtain the colored textile fabric. The colored textile fabric has the advantages of effectively improving moisture absorption and sweat releasing performance and being diversified in functions.

Owner:杭州新天元织造有限公司

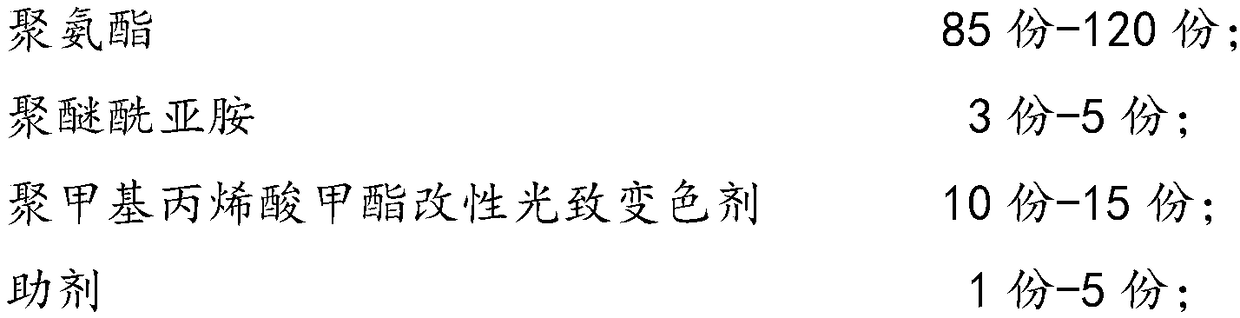

Ultraviolet-proof photochromic polyurethane composite material

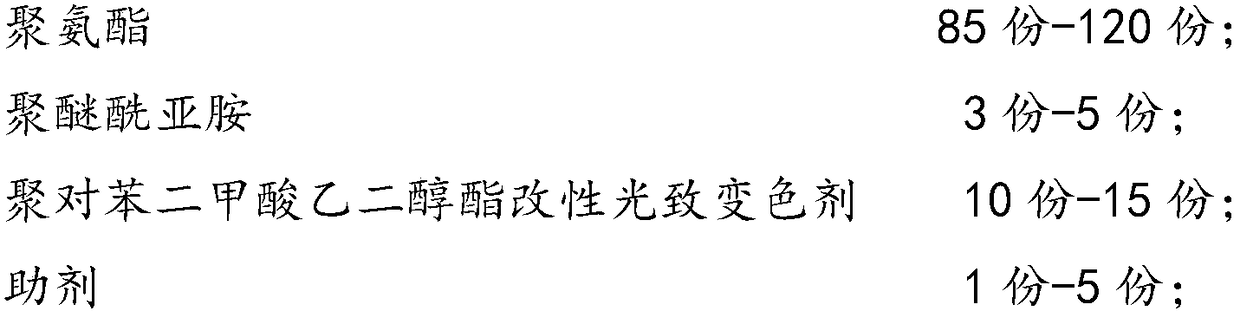

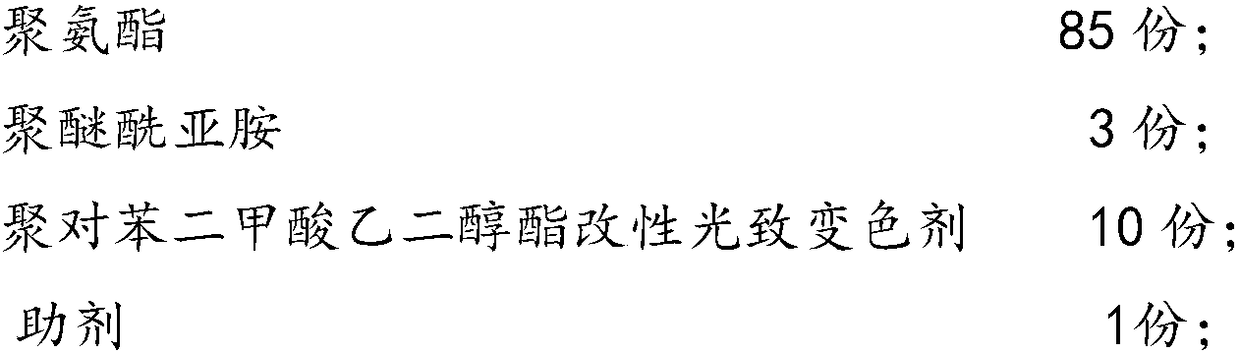

InactiveCN109370195AIncrease color varietyAchieving uniformity of distributionPolyetherimidePolyethylene glycol

The invention relates to an ultraviolet-proof photochromic polyurethane composite material which comprises the following components in parts by weight: 85-120 parts of polyurethane, 3-5 parts of polyetherimide, 10-15 parts of a polyethylene glycol terephthalate modified photochromic agent and 1-5 parts of additives, wherein the photochromic agent comprises an inorganic photochromic agent and an organic photochromic agent. According to the technical scheme, the polyethylene glycol terephthalate modified photochromic agent is added into the polyurethane, and due to coating of the polyethylene glycol terephthalate, the distribution uniformity of the photochromic material in polyurethane is realized. Moreover, the organic photochromic agent is changed into different colors according to different light rays, and the application range of the polyurethane is widened.

Owner:RUGAO FUDA ENG & TECH RES INST CO LTD

Colored plate mobile phone backboard production process

The invention discloses a colored plate mobile phone backboard production process. The production process comprises the following steps: (1) manufacturing a colored plate; (2) transferring a first target texture to the outer surface of the colored plate to form a first texture layer, and forming a first coating layer on the first texture layer; (3) transferring a second target texture to the first coating layer to form a second texture layer; (4) carrying out pressure forming to form a mobile phone backboard blank; (5) forming a second coating layer on the outer surface of the mobile phone backboard blank subjected to pressure forming; (6) spraying a wear-resistant light-cured ink layer; and (7) performing CNC accurate carving, and manufacturing a finished mobile phone backboard product. According to the process, the colored composite plate is adopted, and light is refracted and reflected back and forth in different textures and coating films through splicing combination of two different textures and two layers of covered nano optical coating films, so that a mobile phone can present flowing colors, and the color diversity of the backboard is enhanced.

Owner:SHENZHEN ATES SCI & TECH CO LTD

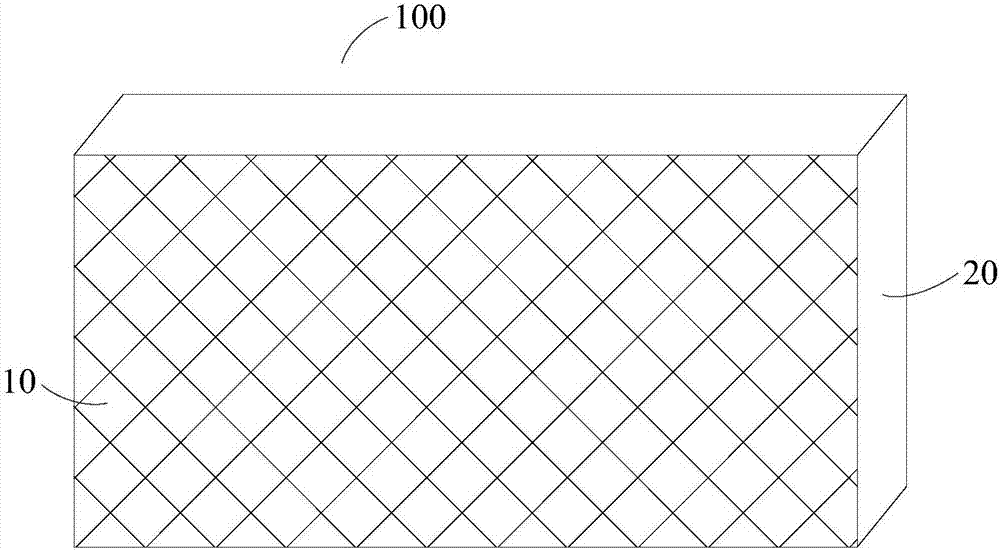

Lamp box fabric and lamp box

PendingCN107300158AIncrease color varietyIncrease profitMechanical apparatusSynthetic resin layered productsLight guideEngineering

An embodiment of the invention provides a lamp box fabric and a lamp box. The lamp box fabric comprises a reflecting layer and a base material layer, wherein the reflecting layer is arranged on one side of the base material layer and made of metal. When visible light is reflected by the reflecting layer, the surface of the lamp box fabric at least present metallic gloss, and a light guide plate and a reflecting piece are sequentially stacked between the base material layer and a fabric layer. As the reflecting layer is arranged in the lamp box fabric, the lamp box fabric can reflect external light, the surface of the lamp box fabric can present the metallic gloss, the lamp box fabric can present gradually varied color effects when being viewed from different angles outside the lamp box fabric, and color diversity of the lamp box can be improved. In addition, owing to the light guide plate and the reflecting piece, the utilization rate of light can be effectively enhanced.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

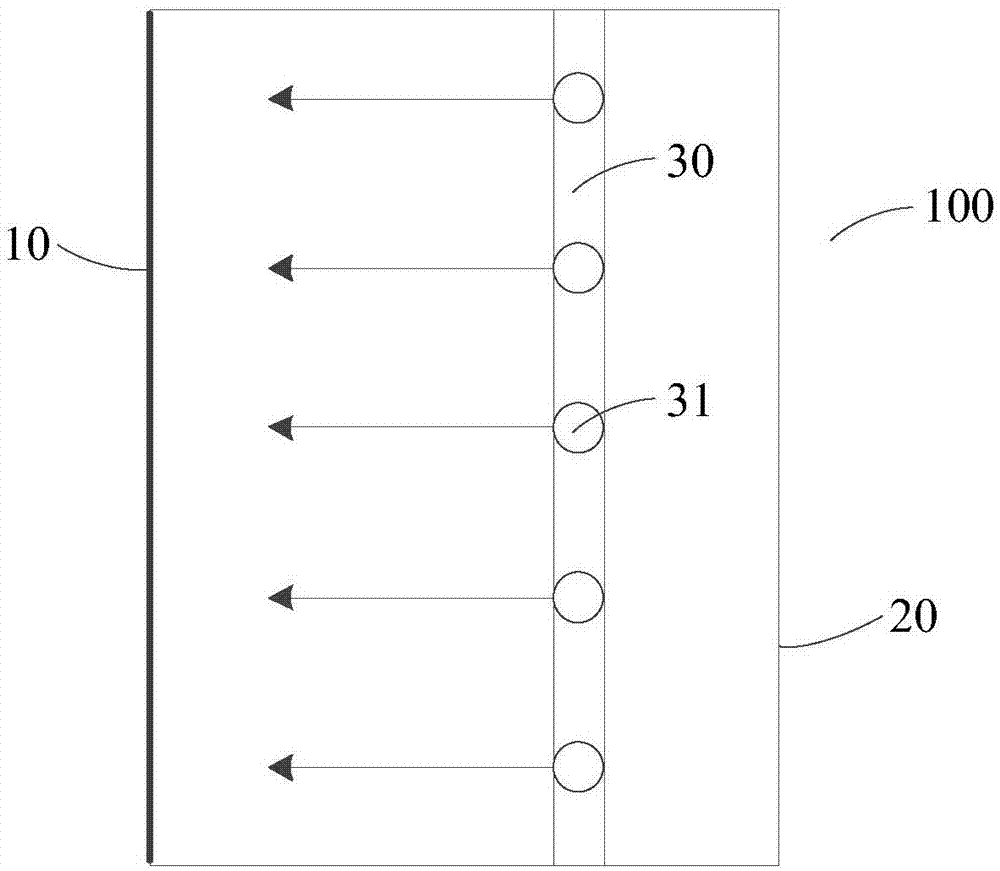

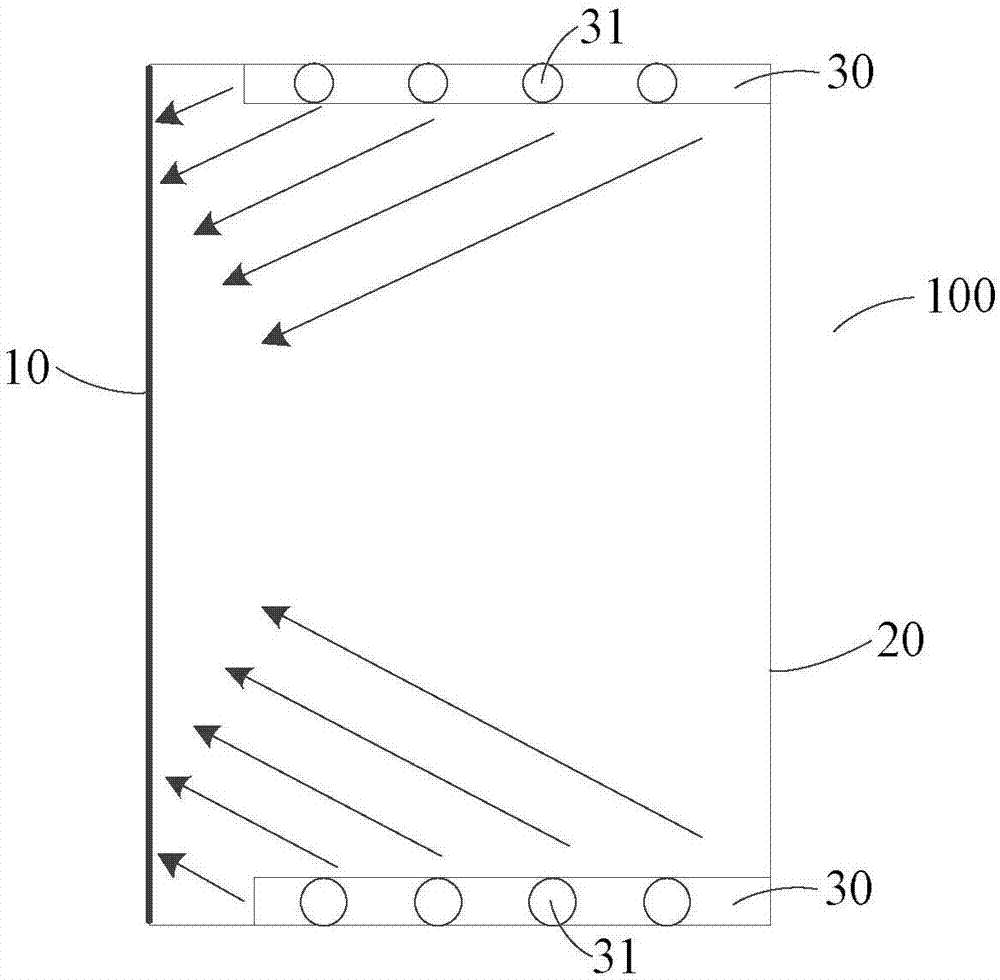

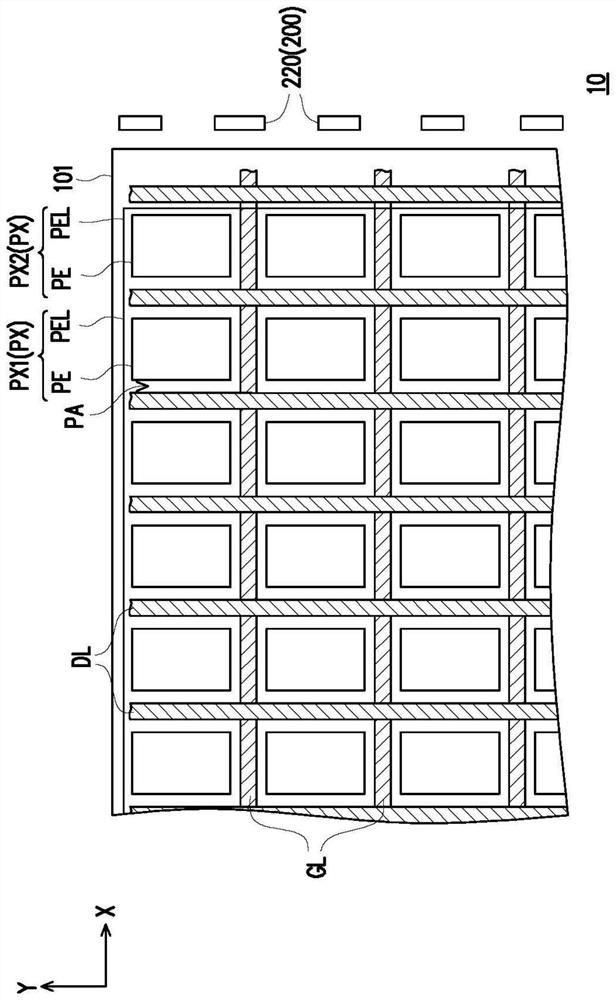

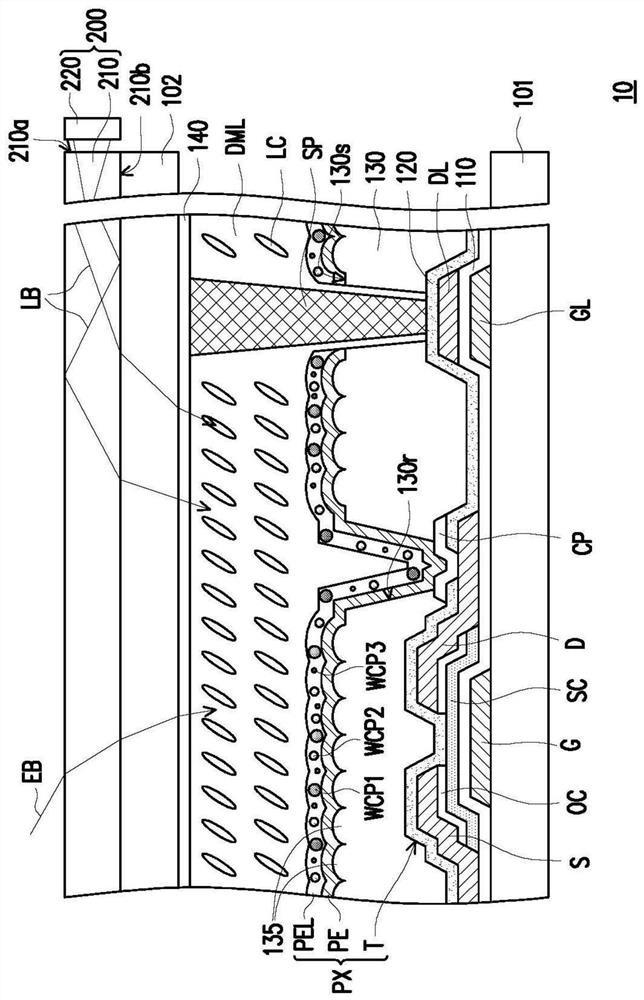

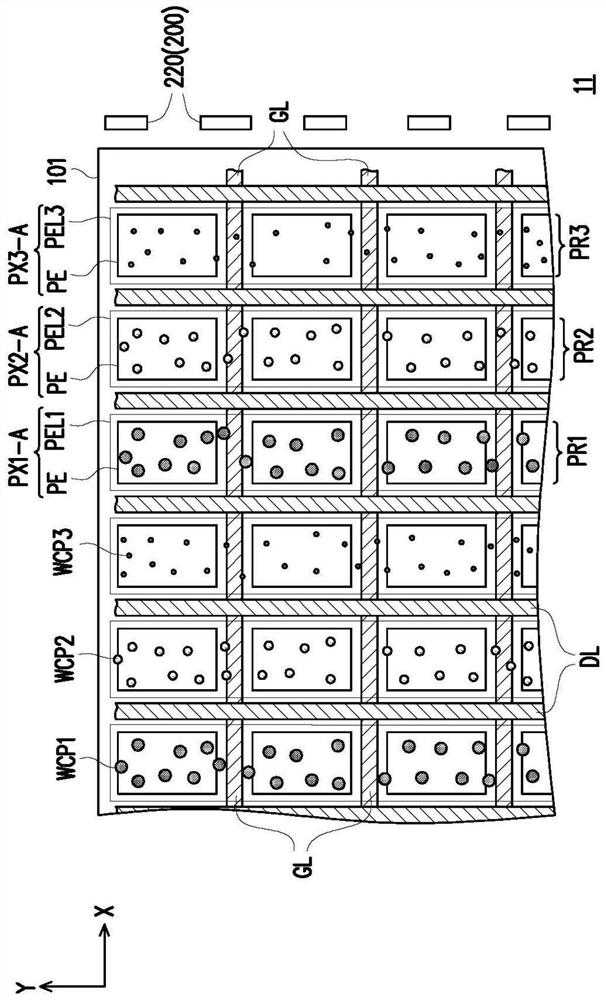

Display panel

PendingCN113960832AIncrease color varietyImprove color vibrancyNon-linear opticsPhysicsLiquid crystal

The invention provides a display panel comprising a first substrate, a second substrate, a plurality of pixel structures and at least one cholesterol liquid crystal layer. The first substrate and the second substrate are arranged opposite to each other. The pixel structures are arranged on the first substrate, and each pixel structure comprises a reflection electrode and a light excitation layer. The reflective electrode overlaps the optical excitation layer and is located between the optical excitation layer and the first substrate. The cholesterol liquid crystal layer is arranged between the first substrate and the second substrate.

Owner:HANNSTAR DISPLAY CORPORATION

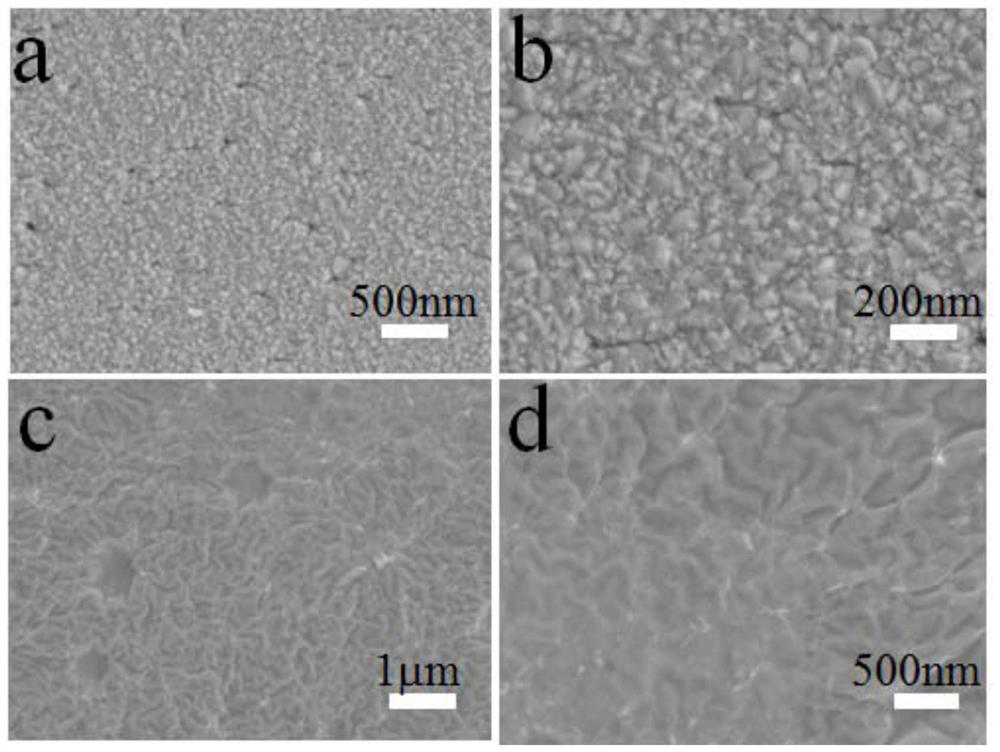

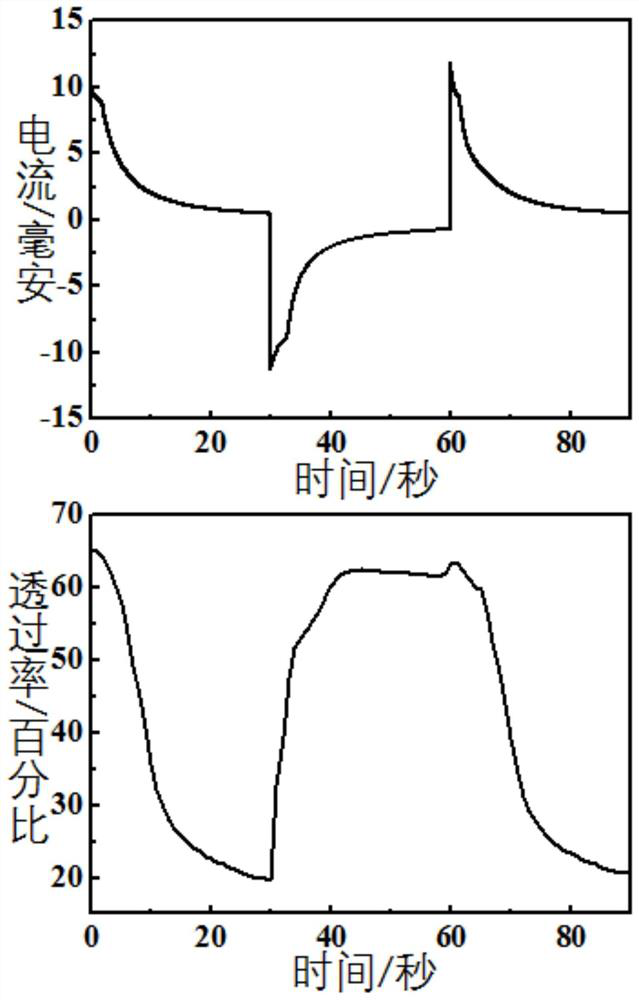

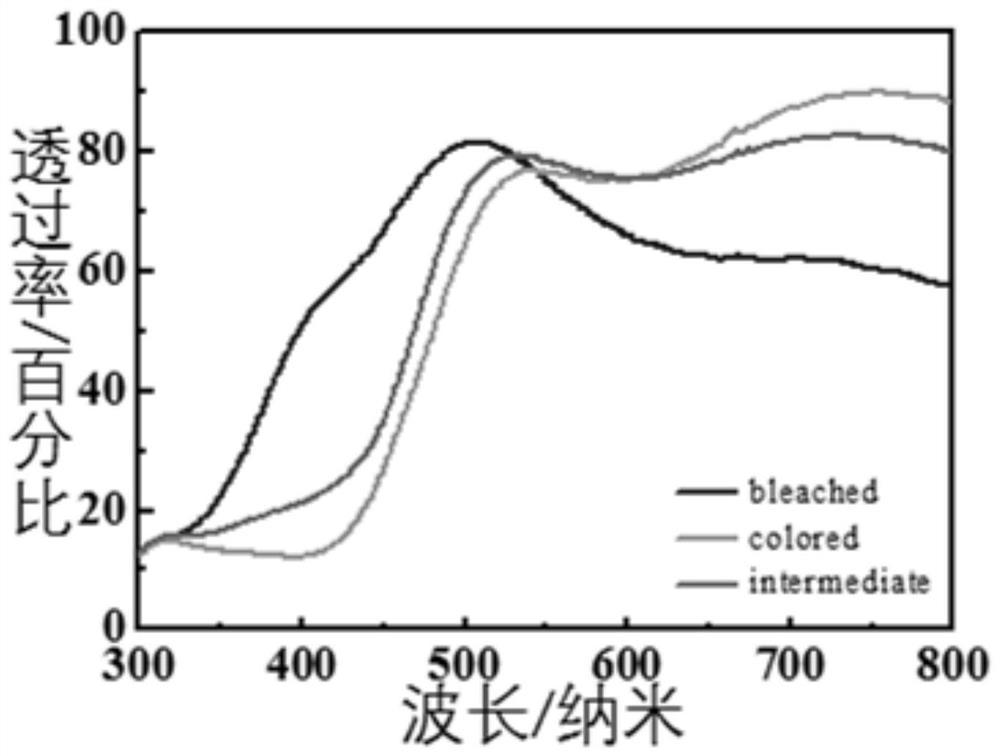

Method for simply and efficiently preparing multicolor all-solid-state electrochromic device

InactiveCN112415826AEasy to assembleReduce uncertaintyNon-linear opticsSolid state electrolytePolyethylene glycol

The invention discloses a method for simply and efficiently preparing a multicolor all-solid-state electrochromic device. The method comprises the step of quickly assembling the all-solid-state electrochromic device by taking a stannic oxide / vanadium pentoxide electrochromic composite film as an electrochromic layer and a polymer solid-state electrolyte as an ionic conductive layer through an ultraviolet curing effect, Wherein the polymer solid electrolyte takes polyethylene glycol diacrylate as a solvent and lithium bis (trifluoromethanesulfonyl) imide as a solute, and the two electrodes arefirmly combined together through polycondensation reaction of polyethylene glycol diacrylate under the action of a photoinitiator. The polymer electrolyte exists in a liquid form before being cured, so that the polymer electrolyte has high wettability when being in contact with the electrochromic layer and the ion storage layer, and the purpose of full contact with an electrode material is achieved. According to the preparation method, the device assembly process is optimized, and a new direction and important reference are provided for design and preparation of the all-solid-state electrochromic device. Meanwhile, the device shows the same color change as the thin film single electrode, and is expected to be truly applied to the field of military camouflage protection.

Owner:ZHEJIANG UNIV

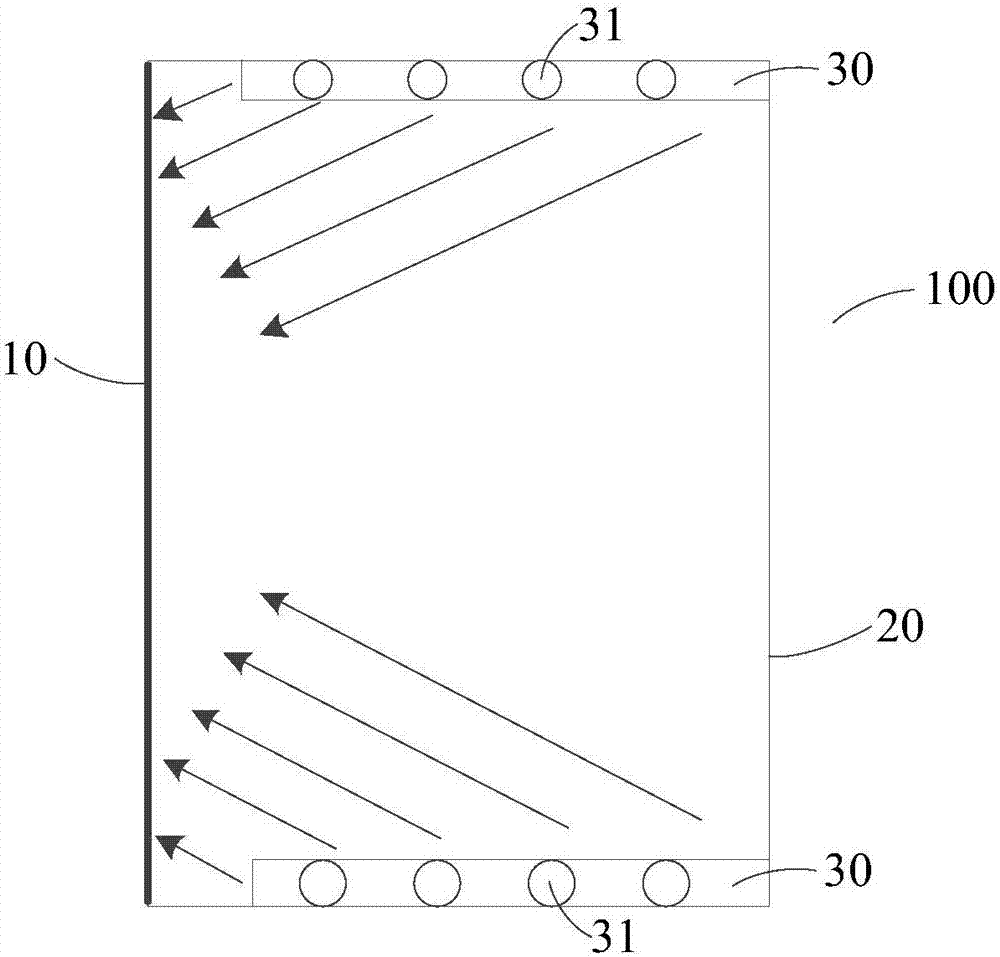

Light box cloth and light box

ActiveCN107283978BIncrease color varietySynthetic resin layered productsIlluminated signsColor effectEngineering

In one embodiment, the invention provides a lamp-box fabric and a lamp-box. The lamp-box fabric includes a reflecting layer, a base material layer and a material distributing layer, which are arranged in a successively laminated manner. A plurality of grooves are formed in one side, which faces to the reflecting layer, of the base material layer, wherein reflecting components are located in the grooves. Materials of the reflecting layer comprise metal. By arranging the reflecting layer in the lamp-box fabric, the lamp-box fabric can reflect external light, so that the surface of the lamp-box fabric has a metal-like luster. By observation at different angles from exterior of the lamp-box fabric, the lamp-box fabric can show a gradual-varying colorful effect; in addition, a plurality of grooves are arranged on the one side, which is towards the reflecting layer, of the base material layer and are filled with the reflecting components, light, which is not utilized by the reflecting layer, is cyclically utilized, thus improving the color diversity of the lamp-box.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Colorful decorative paint difficult to fall off

InactiveCN114410165AKeep the colorGood acid and alkali resistanceLiquid surface applicatorsPolyurea/polyurethane coatingsPolyesterPutty

The invention provides colored decorative paint difficult to fall off, and relates to the field of building paint. The colored decorative paint difficult to fall off comprises primer, decorative paint and protective paint, and the spraying steps are as follows: carrying out surface treatment on a wall surface to be sprayed, smearing putty, troweling the putty, waiting for drying, and preparing the primer and a brushing tool; after the putty is dried, the primer is brushed on the wall surface through a brushing tool, the brushing thickness is 2-3.5 mm, waiting is conducted for 30-50 min till the primer is completely dried, meanwhile, decorative paint is blended, and ground color decorative paint and colored decorative paint are formed. Through a three-layer compounding mode of the primer, the decorative paint and the protective paint, a layer of compact high-transparency paint film is formed through a polyester cross-linking reaction of the protective paint while the primer is used for improving the alkali-resistant and waterproof capacity and the adhesiveness of the inner layer, and the decorative paint is not prone to falling off under the condition that the color of the decorative paint is guaranteed. The acid and alkali resistance and scrubbing resistance of the outer paint surface are improved, the service life of the paint surface is effectively prolonged, and the practicability of the paint surface is enhanced.

Owner:陕西亮业科建设工程集团有限公司

Radiation curing coating, preparation process thereof and product containing coating

PendingCN114749355AHigh hardnessGood adhesionPretreated surfacesWood working apparatusAdhesive cementPolymer science

The invention discloses a preparation process of a radiation curing coating, which comprises the following steps: a radiation curing closed primer, radiation curing putty, a radiation curing solid color primer, a radiation curing sanding primer and a radiation curing finishing coat are sequentially coated on the surface of a base material, and the base material comprises a wood fiber density board, namely an MDF (medium density fiberboard), a multi-layer or single-layer wood board and the like; wherein the radiation curing putty is a selectable coating, and if the base material is a medium-density board or a high-density board, coating of the radiation curing putty can be omitted selectively. The coating disclosed by the invention can replace a melamine impregnated paper veneer process of a density board and a multilayer board in the market, avoids the use of an impregnated veneer which takes formaldehyde as an adhesive in public places and home decoration materials, simplifies a construction process, has good physical and chemical properties such as adhesive force, high hardness, chemical resistance and the like, has excellent color design capability, and can be applied to the field of decoration and decoration. Meanwhile, the method is environment-friendly and cost-saving. All coatings can be subjected to radiation curing, so that assembly line type production of coating is realized, and the production efficiency is greatly improved.

Owner:HUNAN BANFERT NEW MATERIALS TECH

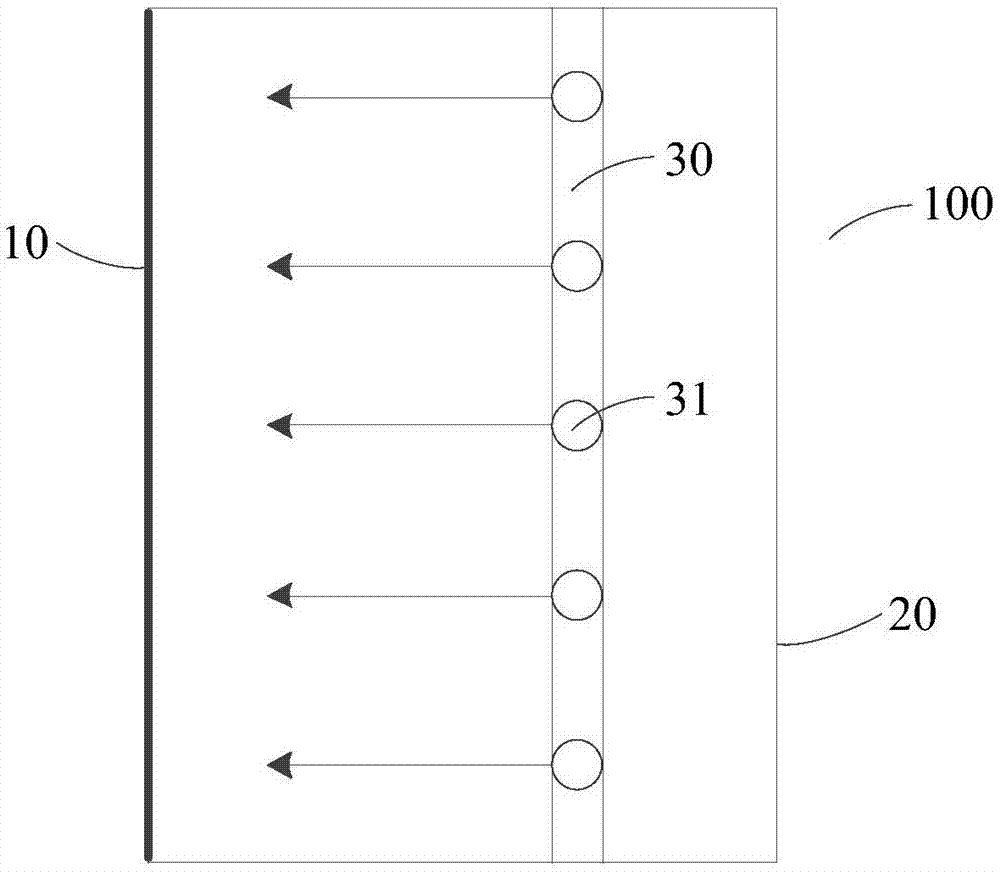

Light box cloth and light box

InactiveCN107175875AIncrease color varietySynthetic resin layered productsIlluminated signsOptoelectronicsReflective layer

An embodiment of the invention provides light box cloth and a light box. The light box cloth comprises a reflecting layer and a base material layer, wherein the reflecting layer is arranged on one side of the base material layer and made of metal and other materials. The surface of the light box cloth at least displays metal gloss when visible light is reflected by the reflecting layer. Due to the fact that the light box cloth is provided with the reflecting layer, the light box cloth can reflect external light to allow the surface of the light box cloth to display metal gloss. When viewed at different angles from the outside of the light box cloth, the light box cloth can display a gradient color, and accordingly color diversity of the light box can be improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

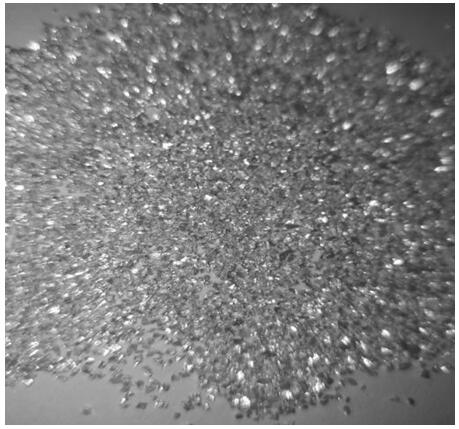

A kind of preparation method of metal silver effect colored sand

The invention discloses a method for preparing colored sand with metallic silver effect. The chemical plating method is mainly used to plate silver metal on the surface of sand and gravel, which mainly includes the following steps: 1) adding pretreated sand and gravel into a container, Distilled water and glucose are fully stirred; 2) Mix a certain amount of silver nitrate with ammonia water or amine, and stir until there is no precipitation; 3) Add the solution in 2) to 1) and stir for a period of time at room temperature, then dry to obtain silver plating colored sand. The preparation process of the present invention is highly efficient, low in cost, high in quality grade, and imparts a strong metallic feeling to the surface of the sandstone.

Owner:MINJIANG UNIV

Light box cloth and light box

ActiveCN107263981BIncrease color varietyEffective coolingSynthetic resin layered productsOptical articlesQuantum dotEngineering

The embodiment of the invention provides lamp box cloth and a lamp box, the lamp box cloth includes a reflection layer and a substrate layer, the reflection layer is arranged on the one side of the substrate layer, the reflection layer comprises a metal material, when visible light is reflected by the reflection layer, the surface of the lamp box cloth shows at least metal luster, a plurality of grooves are arranged on the substrate layer at intervals, and quantum dots are arranged and packed in the grooves. The reflection layer is arranged in the lamp box cloth, so that the lamp box cloth can reflect external light, and the surface of the lamp box cloth shows the metal luster, when the lamp box cloth is observed from different external angles, a gradient color effect can be shown by the lamp box cloth, the color diversity of the lamp box can be enhanced; in addition, due to the arrangement of the quantum dots, purposes of effective heat dissipation and wide color gamut can be achieved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Colorful SMC material applied to bathroom products and preparation method thereof

The invention discloses a colorful SMC material applied to bathroom products, which comprises the following components in percentage by weight: 65.9-73% of continuous-phase resin paste, 1-3% of dispersed-phase color matching base paint, 1-1.6% of a thickener and 25-30% of alkali-free glass fibers, and the sum of the weight percentages of the components is 100%. The invention also provides a preparation method of the colorful SMC material. The colorful SMC material disclosed by the invention has the advantages of good surface gloss, various colors, good product color stability, good mechanicalstrength and simple production process.

Owner:广东百汇达新材料有限公司

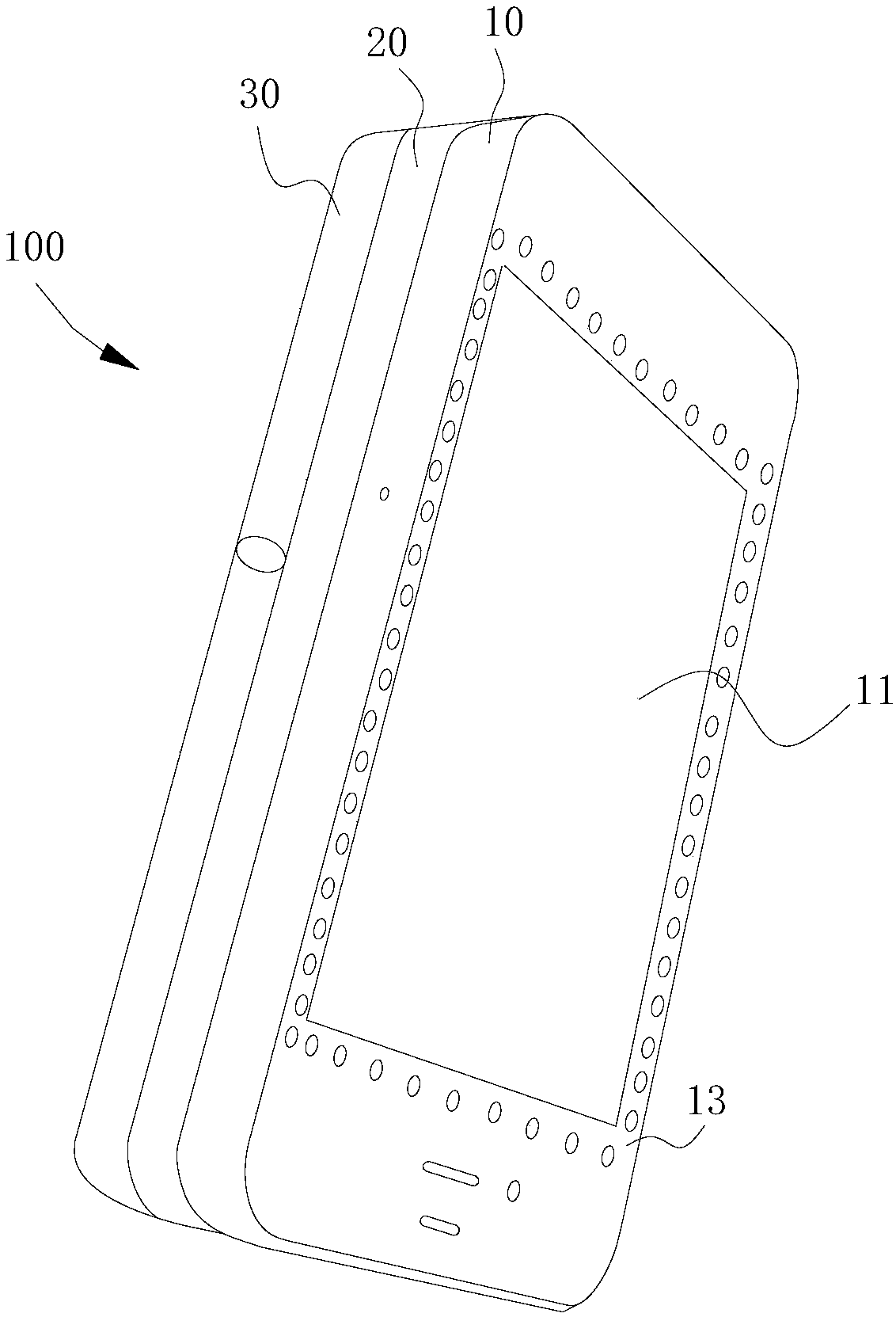

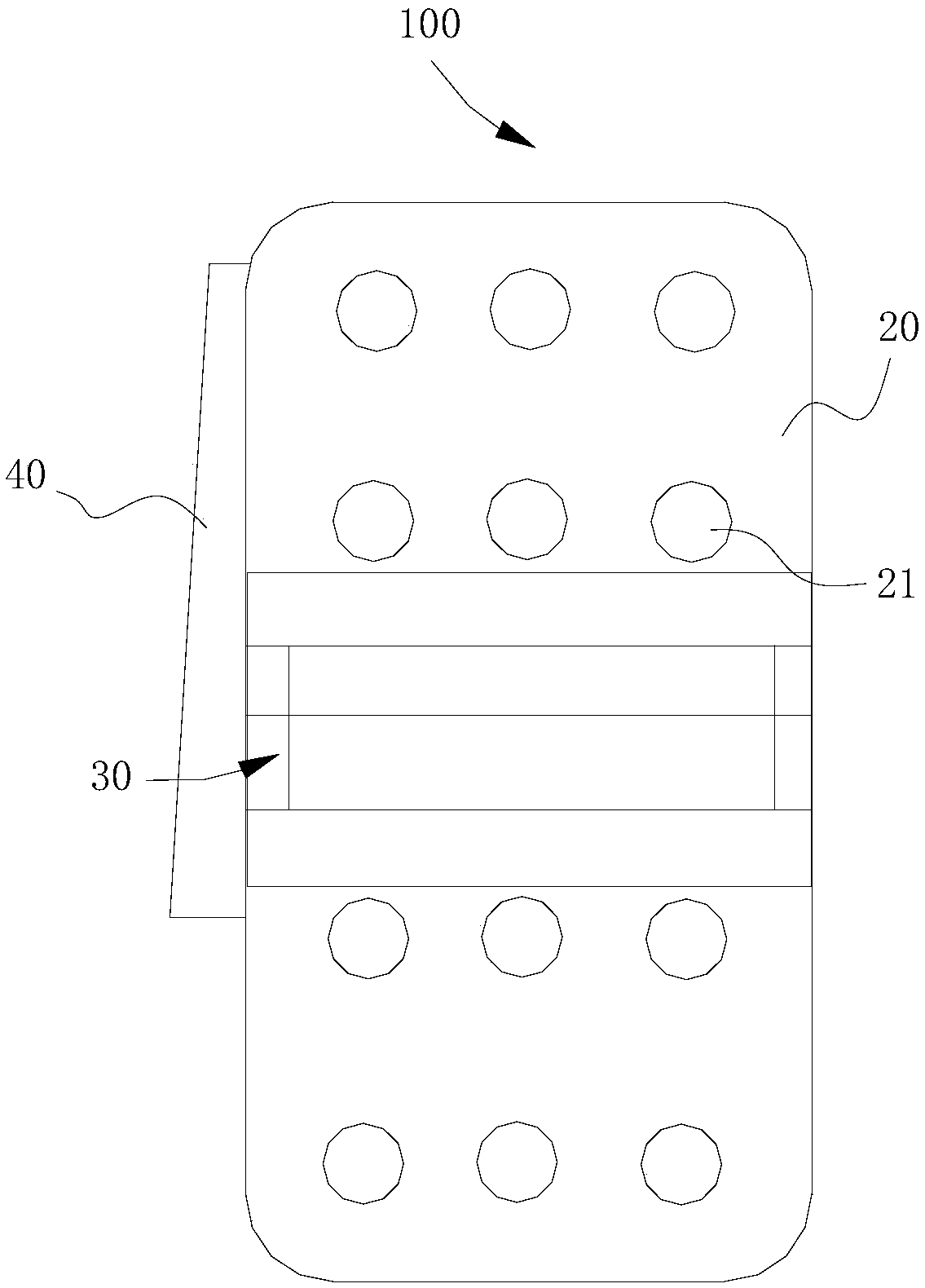

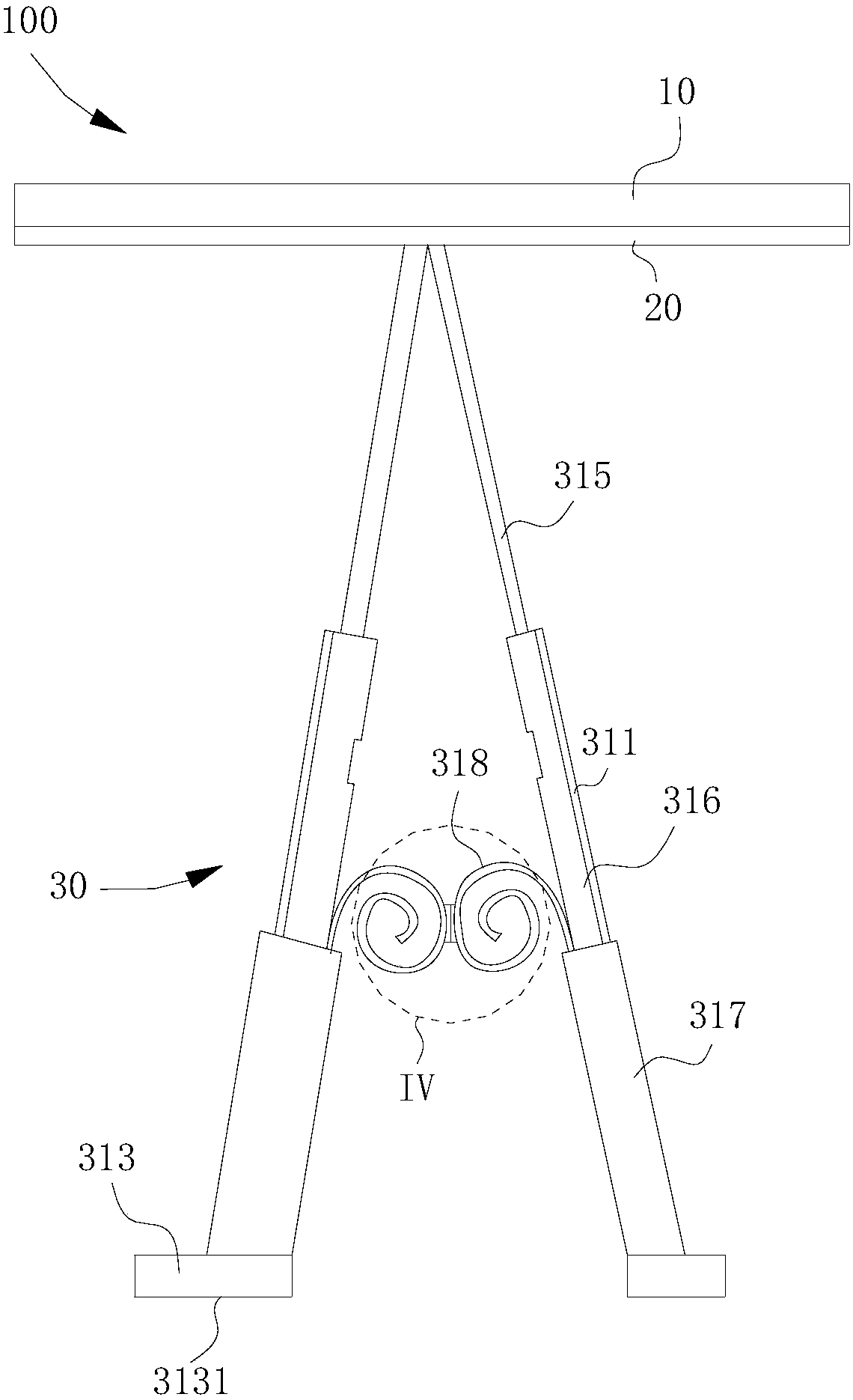

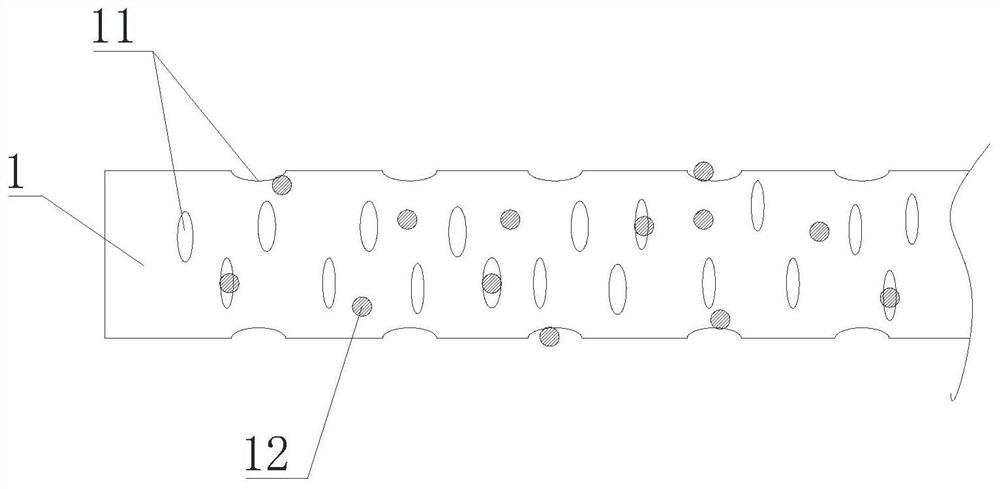

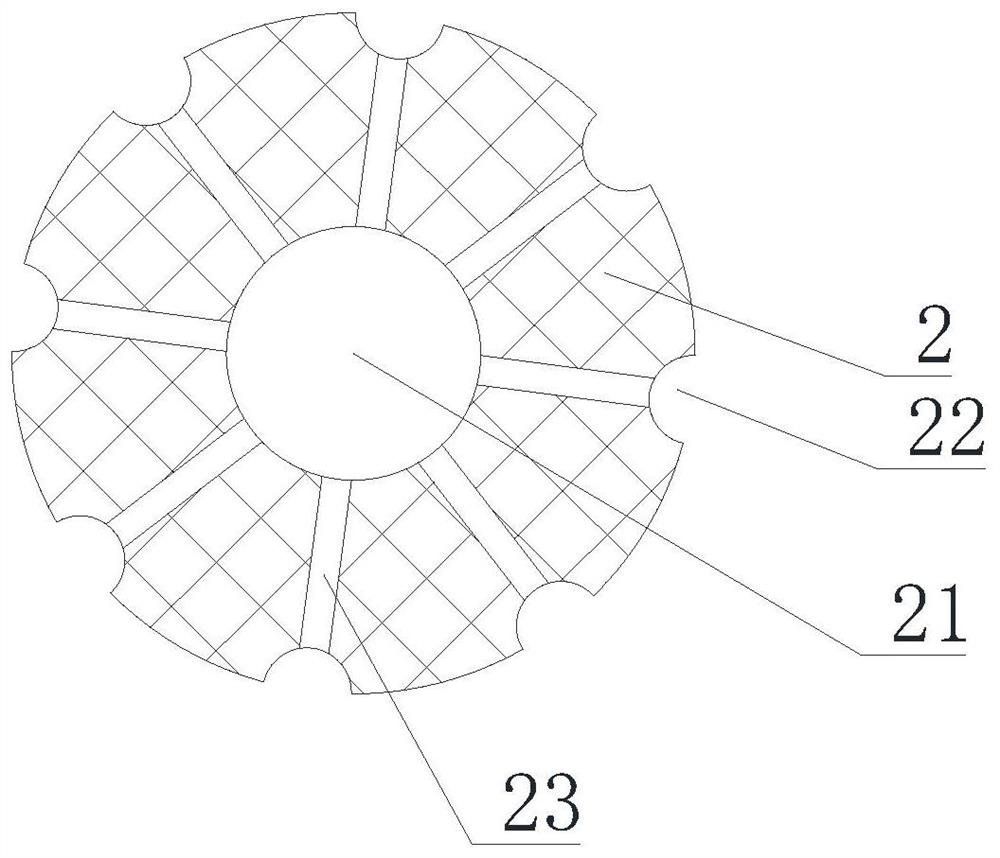

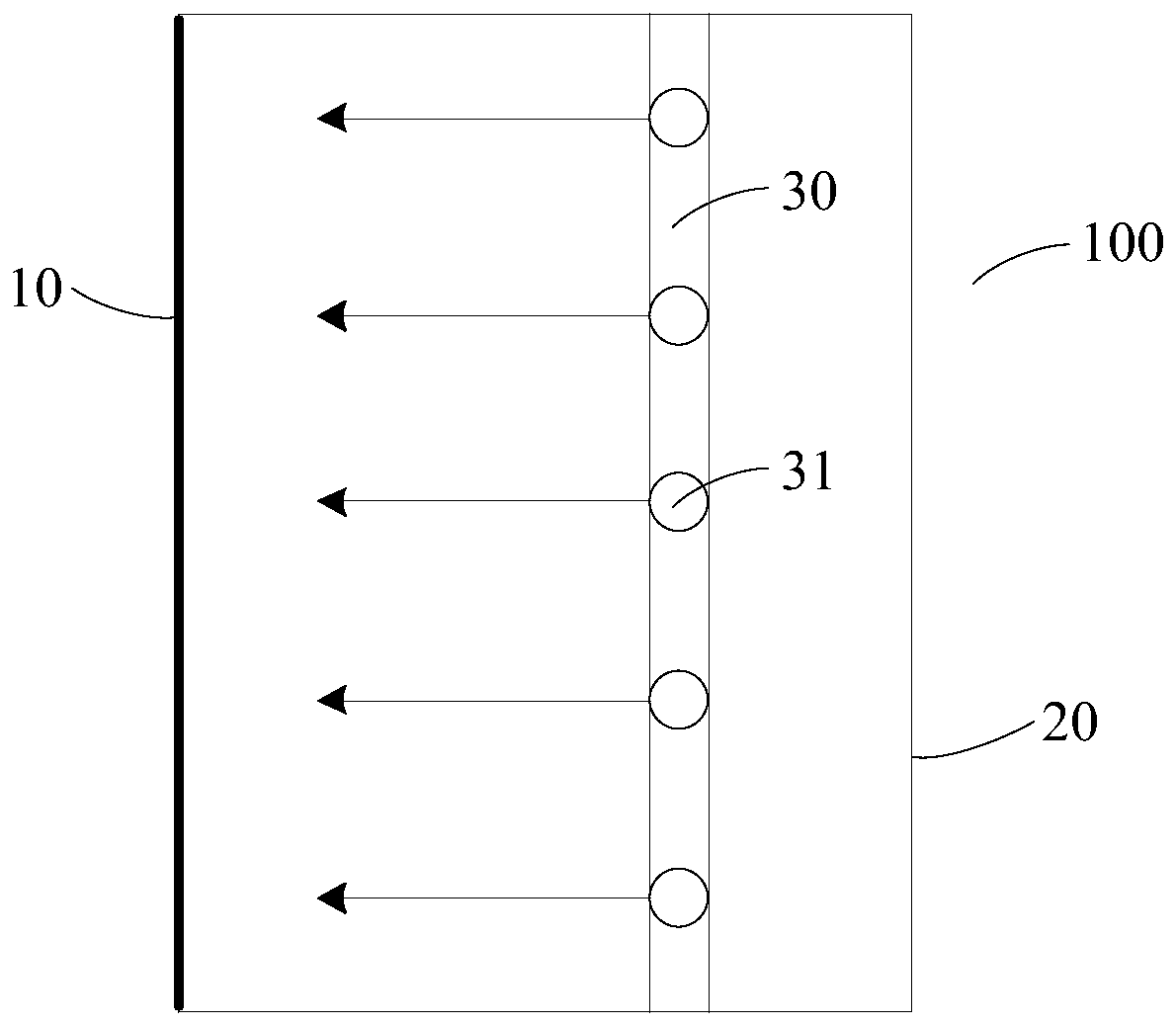

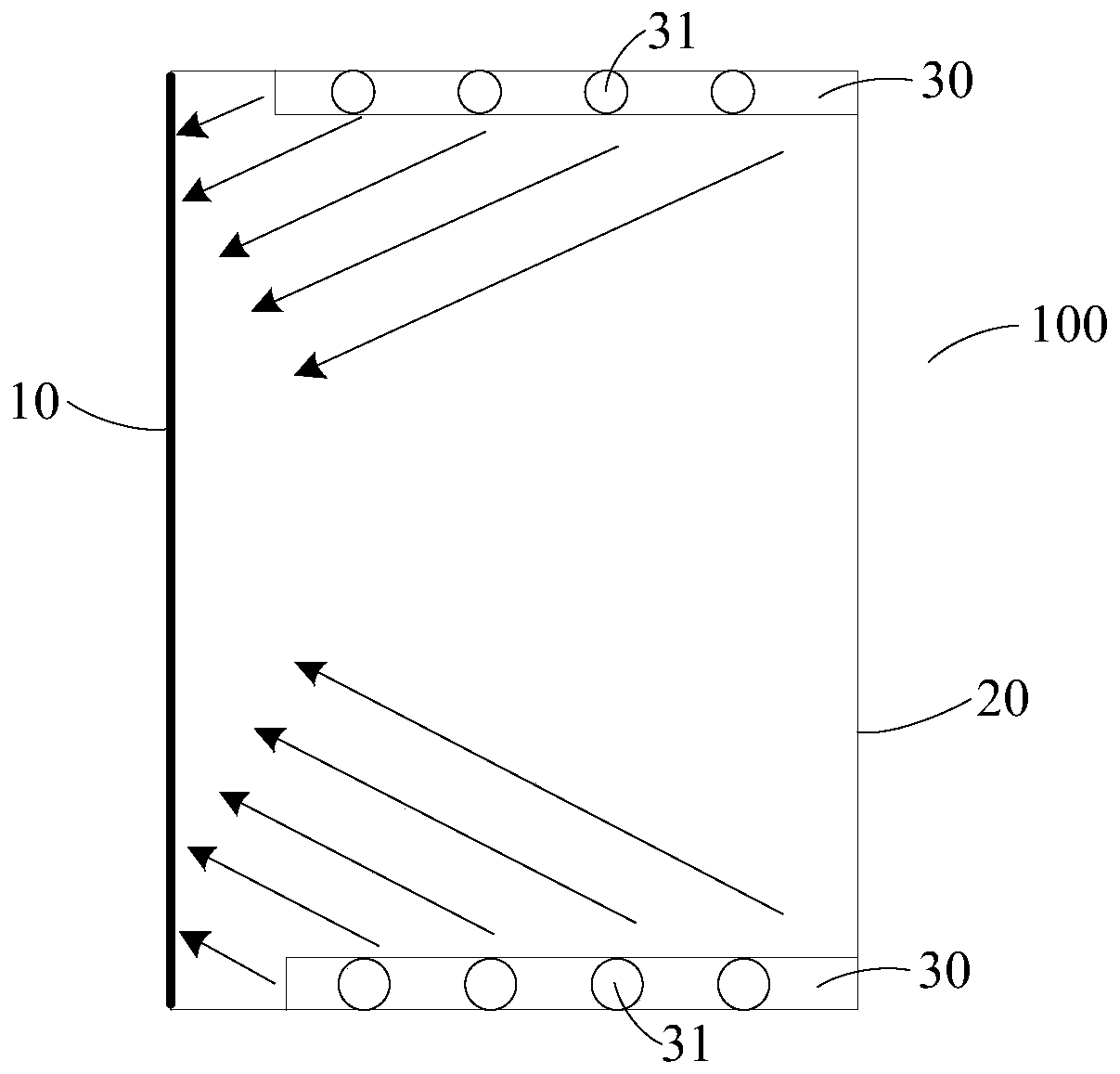

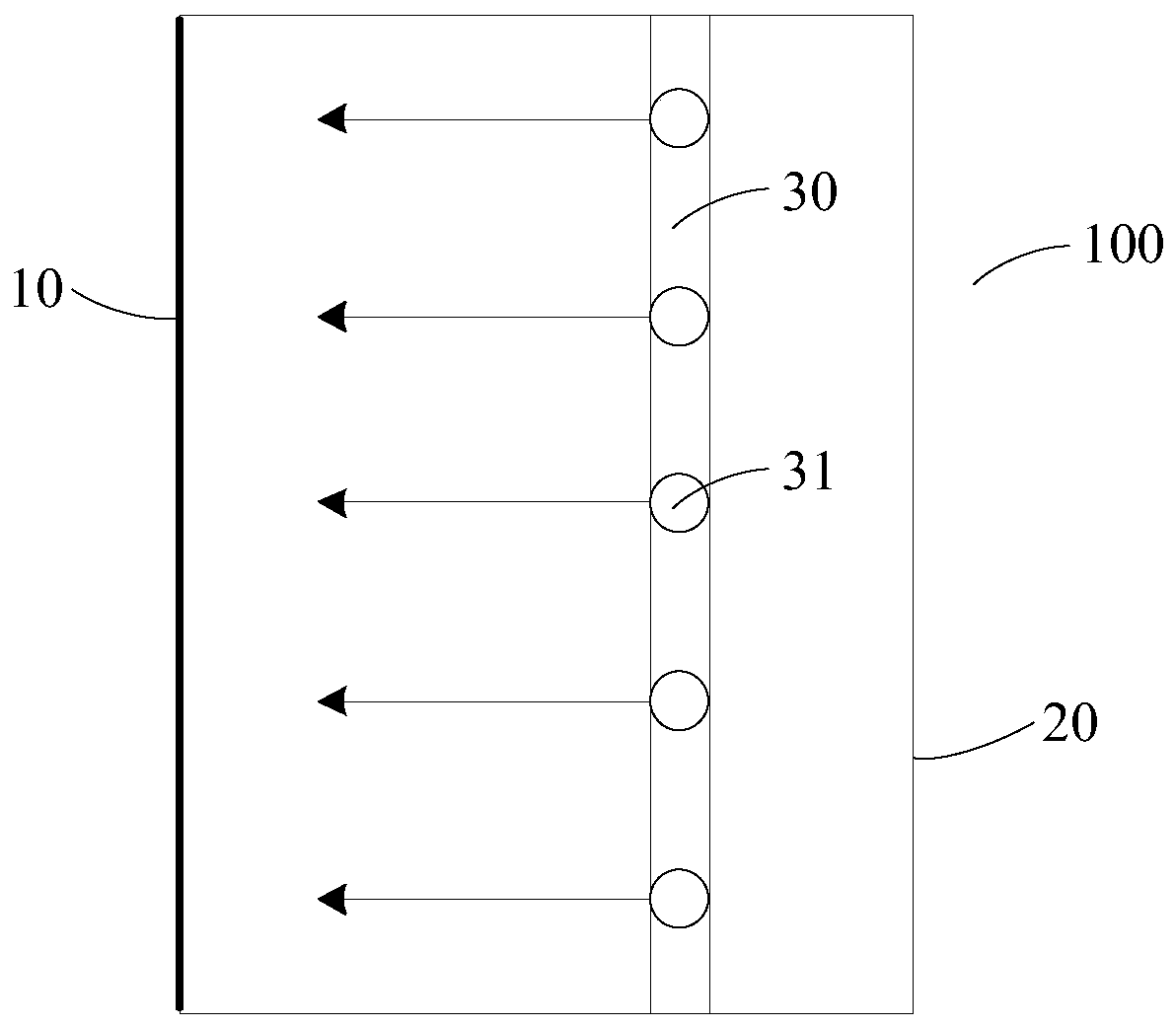

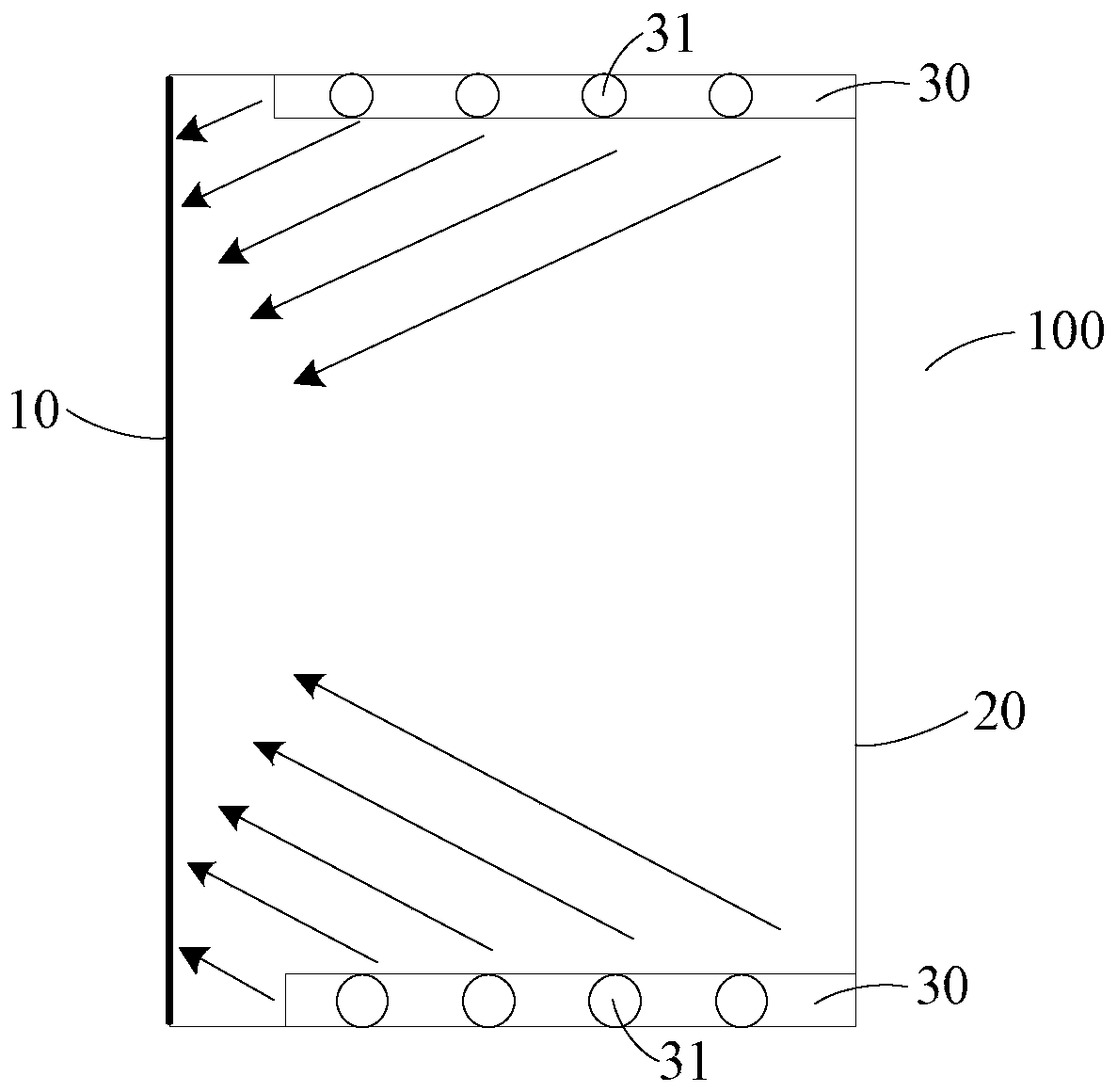

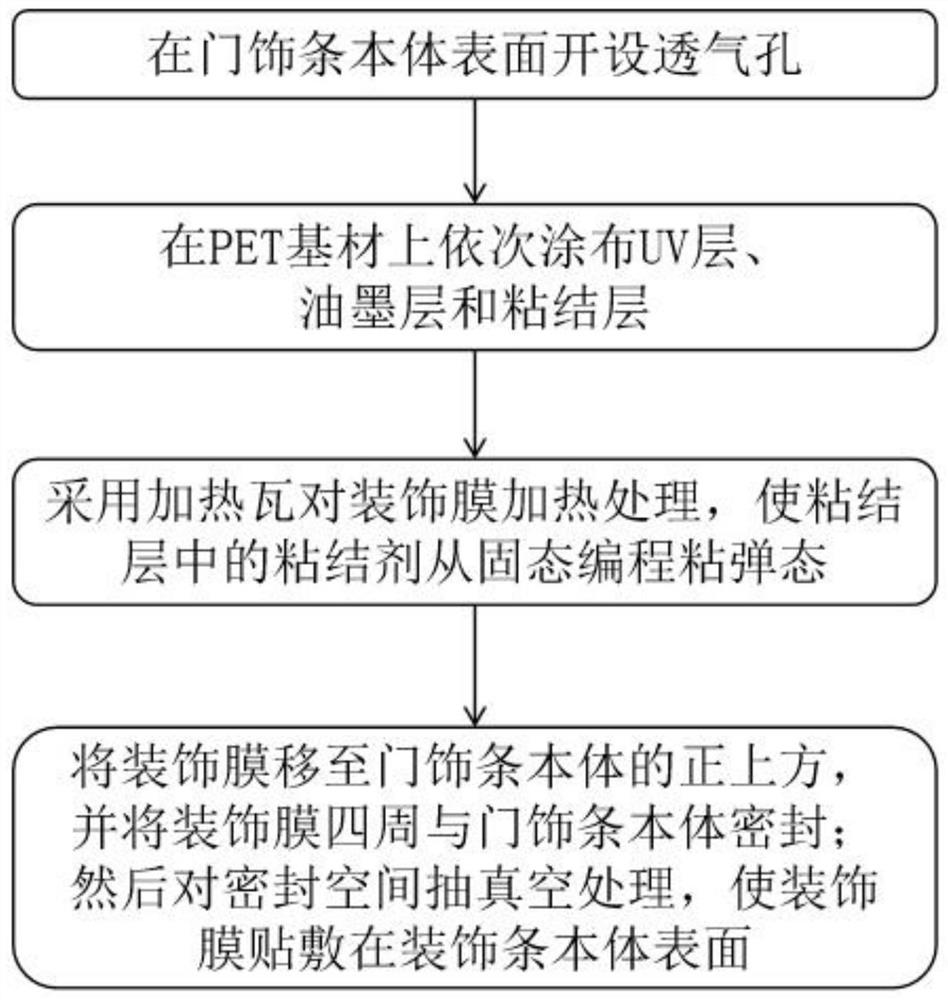

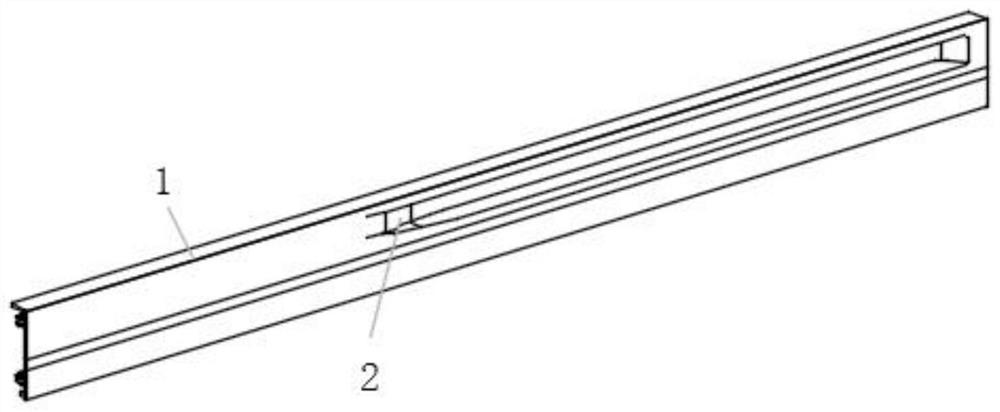

A refrigerator door trim strip and its surface treatment method

ActiveCN110319642BHigh hardnessIncrease color varietyLighting and heating apparatusCooling fluid circulationStructural engineeringMechanical engineering

The invention discloses a refrigerator door trim and a surface treatment method thereof, and relates to the technical field of door trim surface treatment. The present invention comprises a door trim body; a rectangular groove is provided on the door trim body; a 3D special-shaped curved surface is provided at the connection between the rectangular groove and a surface of the door trim body; a number of ventilation holes are provided on the door trim body The surface of the door trim body is sealed with a decorative film; the decorative film includes a PET base material, a UV layer, an ink layer, and an adhesive layer sequentially from the inside to the outside. The present invention moves the decorative film to the top of the door trim body by opening air holes on the surface of the door trim body, and seals the surroundings of the decorative film with the door trim body; then vacuumizes the sealed space to make the decorative film stick Coated on the surface of the decorative strip body, it has high hardness and high color diversity; it is environmentally friendly and efficient; it solves the problem that the IMD process cannot be applied to curved surfaces with large R angles, especially 3D special-shaped surfaces.

Owner:CHANGHONG MEILING CO LTD

Lamp box cloth and lamp box

ActiveCN107170386AIncrease color varietySynthetic resin layered productsVacuum evaporation coatingColor effectEngineering

The embodiment of the invention provides lamp box cloth and a lamp box. The lamp box cloth comprises a reflecting layer, a base material layer and a cloth material layer, wherein the reflecting layer, the base material layer and the cloth material layer are arranged in a sequential stacking manner, a first binder is arranged between the base material layer and the cloth material layer, miniature holes are formed in one side, close to the cloth material layer, of the base material layer, at least one part of the first binder is positioned in the miniature holes in the base material layer, the reflecting layer is made of metal, and the cloth material layer has light transmission. According to the technical scheme, the reflecting layer is arranged in the lamp box cloth, therefore, the lamp box cloth can reflect external light rays, thus the surface of the lamp box cloth can show the metallic luster, when observation is carried out from different angles of the outside of the lamp box cloth, the lamp box cloth can show the gradually variational color effect, and thus the color diversity of the lamp box can be improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

A kind of processing method of woolen fabric and finished garment with surface gradient color effect

The invention discloses a processing method of a wool fabric and wool ready-to-wear clothes having surface gradient color effect and aims to provide a method by that the gradient color effect is formed from one end to the other end of the wool fabric and wool ready-to-wear clothes. The method includes the steps of: adding a wool chlorination modifier to a penetrating agent solution to prepare a wool chlorination modifying treatment liquid; at constant speed, immersing one end of the wool fabric and wool ready-to-wear clothes in the wool chlorination modifying treatment liquid until the other end is immersed to perform wool chlorination modification to different degrees; dyeing the wool fabric and wool ready-to-wear clothes, after the chlorination modification, to prepare the product, wherein a dark-to-light gradient color effect is formed from one end to the other end of the surfaces of the wool fabric and wool ready-to-wear clothes. The method can form the gradient color effect, whichhas abundant color layers and natural transition, on the wool fabrics, so that color diversification and individuation of wool fabric products is improved.

Owner:山东神州毛纺织有限公司

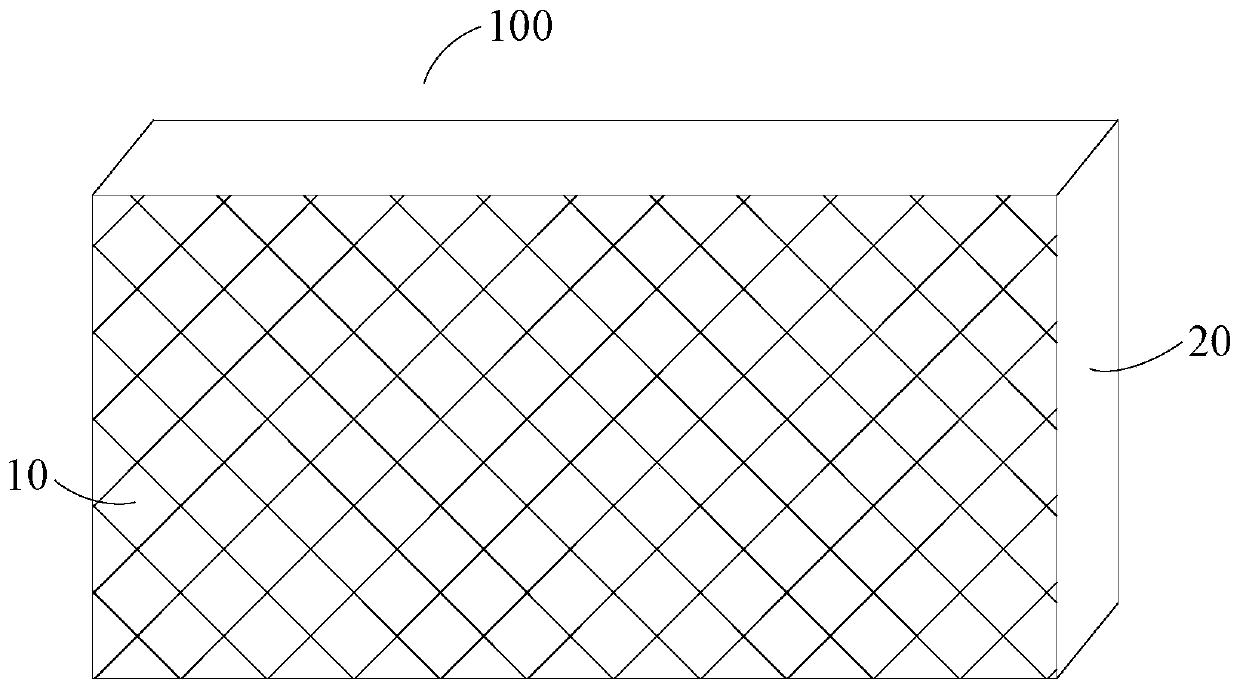

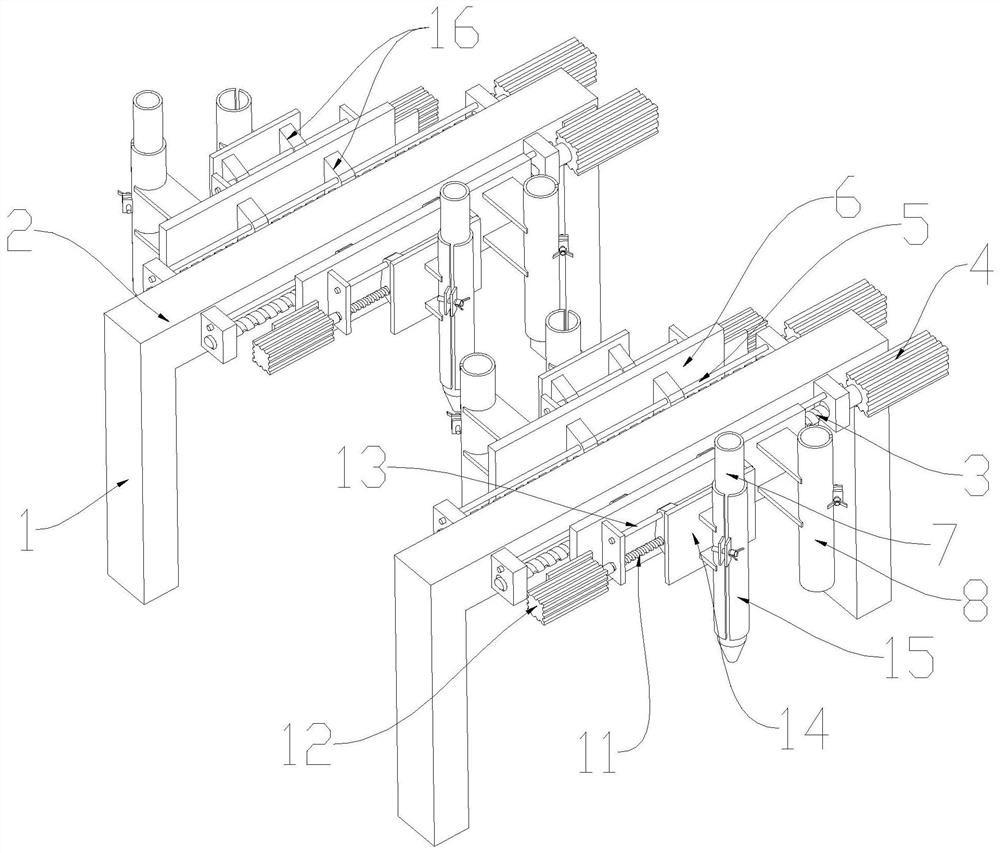

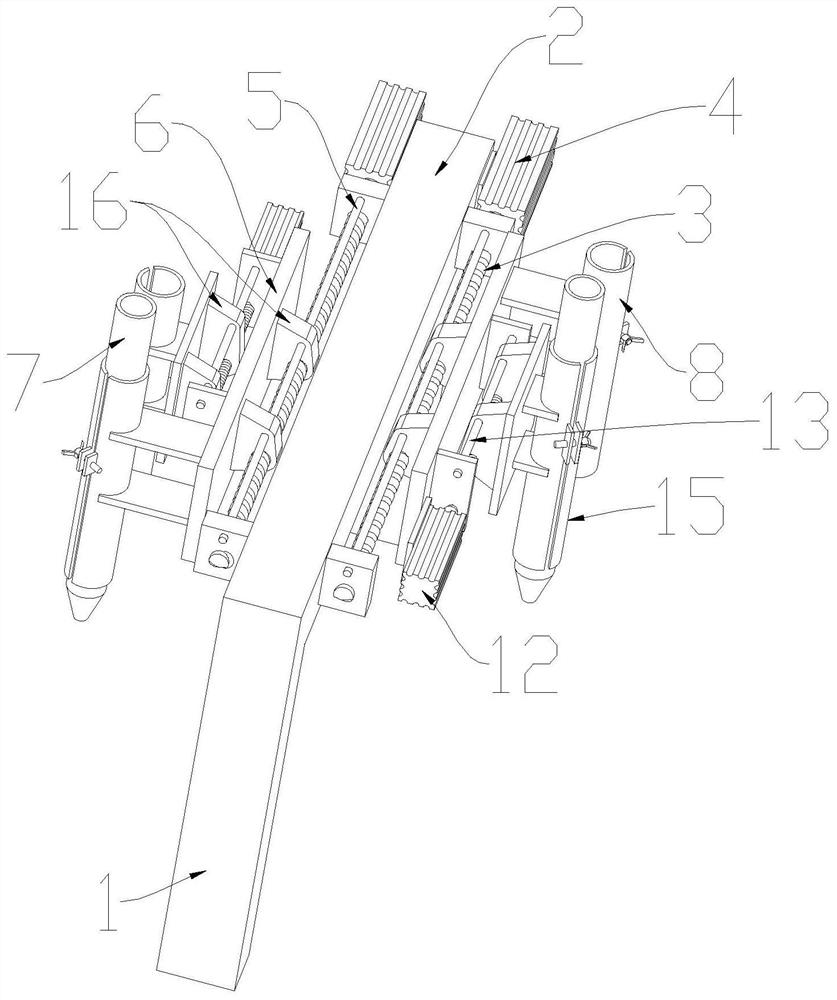

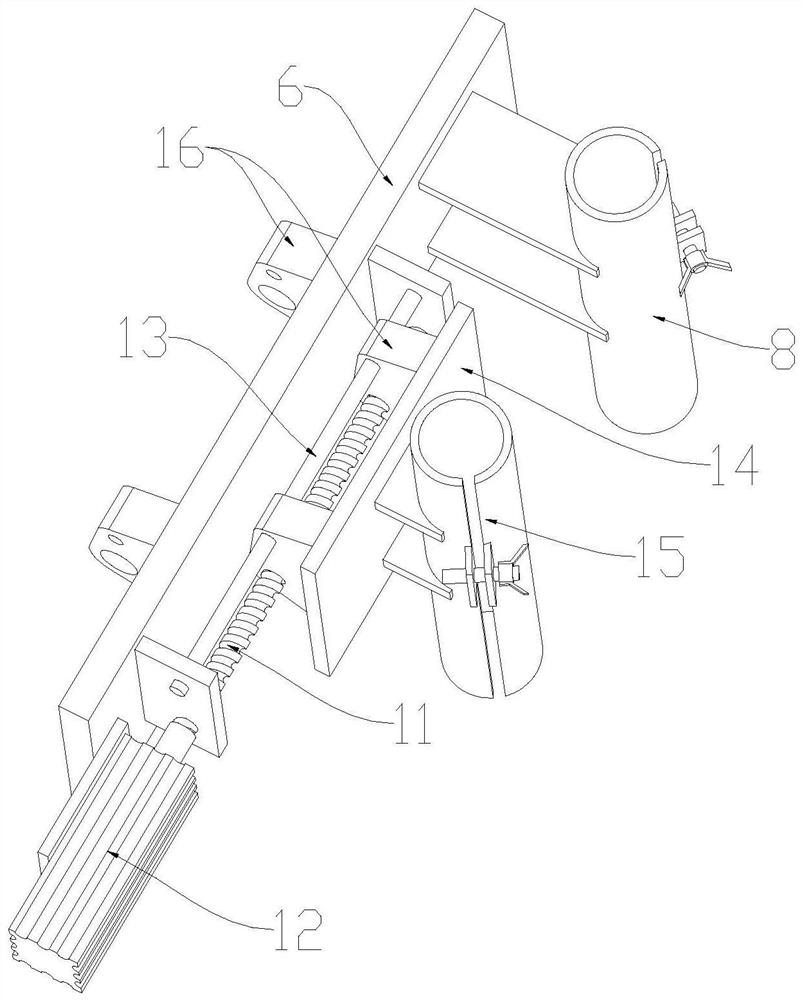

Multi-axis simulation grain pouring mechanism

The invention provides a multi-axis simulation grain pouring mechanism. The multi-axis simulation grain pouring mechanism comprises a plurality of portal frames, and main transmission shafts, main driving motors, main sliding rods and main sliding plates are arranged on the two opposite side walls of cross beams of the portal frames. The main transmission shafts are rotationally installed on the side walls of the portal frames, and output shafts of the main driving motors are connected with the main transmission shafts. The main sliding rods are arranged on the side walls of the portal frames,the main sliding plates are in sliding connection with the main sliding rods and are further in threaded connection with the main transmission shafts, and the main transmission shafts drive the mainsliding plates to slide on the main sliding rods. Main clamping pipes are arranged on the main sliding plates. Due to the fact that the multiple portal frames are erected above a forming groove, mainclamping pipes and auxiliary clamping pipes which can move towards or away from each other on the cross beams are designed on the portal frames, auxiliary color pouring guns are installed on the mainclamping pipes and the auxiliary clamping pipes, and during grain drawing operation, the different main clamping pipes and auxiliary clamping pipes are controlled to make relative movement, the purpose of drawing a plurality of grain lines and drawing crossed tree-shaped grain lines in the main color paste at the same time can be achieved.

Owner:ZHUHAI SHENGXIYUAN MECHANICAL & ELECTRICAL EQUIP CO LTD

Lamp box cloth and lamp box

InactiveCN107379677AIncrease color varietySynthetic resin layered productsIlluminated signsEngineeringTextile

An embodiment of the invention provides lamp box cloth and a lamp box. The lamp box cloth comprises a reflection layer, a substrate layer and a fabric layer which are stacked sequentially, wherein first cords extend from the edge of the substrate layer and are attached to the edge of the fabric layer; the material of the reflection layer includes metal. According to the scheme, the reflection layer is arranged in the lamp box cloth, so that the lamp box cloth can reflect outside light, the surface of the lamp box cloth can show metal luster, the lamp box cloth can have a gradually varied color effect when observed from different angles outside the lamp box cloth, and the color variety of the lamp box can be improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

A kind of ultra-high weather resistance PVC co-extruded surface layer material and its manufacturing method

The invention an ultrahigh-weather-resistance PVC (polyvinyl chloride) coextruded surface material and a manufacturing method thereof, belonging to the field of composite materials. The ultrahigh-weather-resistance PVC coextruded surface material comprises the following components in parts by mass: 40-60 parts of PVC powder, 20-50 parts of CPVC (chlorinated polyvinyl chloride), 10-20 parts of calcium carbonate powder, 0.4-6 parts of stabilizer, 4-7 parts of impact modifier, 1-3 parts of lubricant, 0.4-0.9 part of anti-ultraviolet agent, 0.4-0.9 part of antioxidant, 0.5-1 part of antistatic agent, 3-6 parts of whisker and 3-6 parts of toner. By adjusting the formula, the material has comparable weather resistance with ASA (acrylonitrile-styrene-acrylate), and has higher surface hardness and Vicat softening point temperature. The material is low in cost, does not need to depend on import, and can obviously lower the production cost. The production cost of the product is only about one half of that of the ASA material. The product can be widely used in surface coextrusion of PVC door / window profiles, PVC wood-plastic profiles and PVC tiles to enhance the physical properties and colorfulness of the product.

Owner:DONGGUAN BETTO WOOD NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com