A kind of preparation method of metal silver effect colored sand

A metal silver and colored sand technology, which is applied in the field of artificial colored sand preparation, can solve the problems of poor weather resistance, color and luster that cannot meet the decoration requirements, etc., and achieve the effects of improving economic benefits, enhancing gloss and color richness, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh 10g of quartz sand sieved with 50 mesh, add 40ml of distilled water and stir for 20min, add 1g of SnCl 2 , and 0.3g of 32wt% concentrated hydrochloric acid, add 50ml of distilled water, stir and react for 30min, then take it out and rinse with distilled water, filter, and dry to obtain pretreated quartz sand.

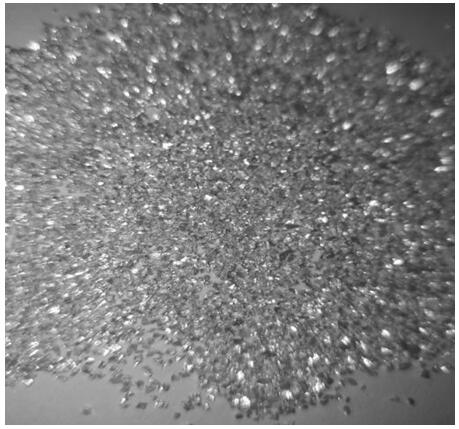

[0031] Weigh 1g glucose, 1gAgNO 3 , 3g diethanolamine, 80ml distilled water to prepare a plating solution, add 10g of pretreated quartz sand, stir and react at room temperature for 30min, then wash with distilled water, filter, and dry at 100°C for 1h to obtain colored sand with silver-plated surface. From figure 1 It can be seen from the figure that the surface of the chemically silver-plated colored sand has a strong metallic feel and has the flashing characteristics of silver alone, which can improve the decorative effect of the colored sand.

Embodiment 2

[0033] Weigh 10g of yellow sand sieved with 50 mesh, add 40ml of distilled water and stir for 20min, add 1g of SnCl 2 , and 0.3g of 32wt% concentrated hydrochloric acid, add 50ml of distilled water, stir and react for 30min, then take it out and rinse with distilled water, filter, and dry to obtain pretreated quartz sand.

[0034] Weigh 1g glucose, 1gAgNO 3 , 3g diethanolamine, 80ml distilled water to prepare a plating solution, add 10g of pretreated quartz sand, stir and react at room temperature for 30min, then wash with distilled water, filter, and dry at 100°C for 1h to obtain colored sand with silver-plated surface. From figure 2 It can be seen from the figure that the surface of the chemically silver-plated colored sand has a strong metallic feel and has the flashing characteristics of silver alone, which can improve the decorative effect of the colored sand.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com