Production process of moisture-absorbing, sweat-releasing and antibacterial colored textile fabric

A technology for moisture absorption and perspiration production, which is applied in fabrics, textiles, textiles and papermaking, etc., can solve the problems of the need to strengthen the moisture absorption and perspiration performance, the single direction of moisture absorption and water absorption, and the poor antibacterial performance of fabrics, so as to increase the antibacterial and Color richness, improved moisture wicking performance, strong adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A production process of moisture-wicking and antibacterial colored textiles, comprising the following steps:

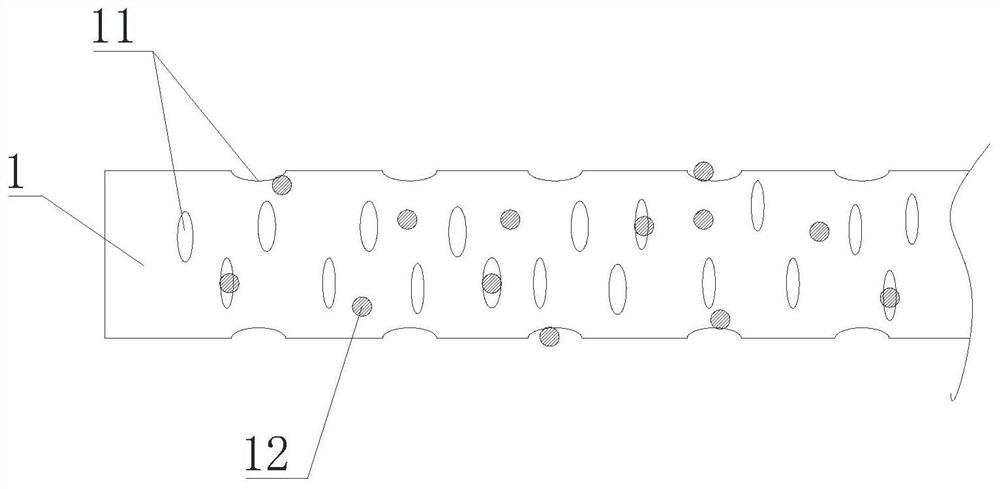

[0030] S1: Add colorant and antibacterial particles 12 to polyester fiber spinning solution to make modified antibacterial polyester fiber; the surface of the modified antibacterial polyester fiber 1 is provided with transverse micropores 11, modified antibacterial The interior of the polyester fiber is provided with longitudinal micropores 11;

[0031] S2: blending modified antibacterial polyester fiber and viscose fiber in a ratio of 60 / 40 to obtain blended yarn a;

[0032] Blending modified antibacterial polyester fiber and viscose fiber in a ratio of 60 / 40 to obtain blended yarn b;

[0033] S3: doubling the blended yarn a to obtain double-ply warp yarns;

[0034] S4: core-spun blended yarn b and spandex to obtain weft yarn;

[0035] Wherein, the count of the blended yarn a is 32S, the count of the blended yarn b is between 32S, and the count of the spand...

Embodiment 2

[0039] A production process of moisture-wicking and antibacterial colored textiles, comprising the following steps:

[0040] S1: Add colorant and antibacterial particles to the polyester fiber spinning solution to make modified antibacterial polyester fiber 1; the surface of the modified antibacterial polyester fiber 1 is provided with transverse micropores 11, modified antibacterial The interior of the polyester fiber is provided with longitudinal micropores 11 .

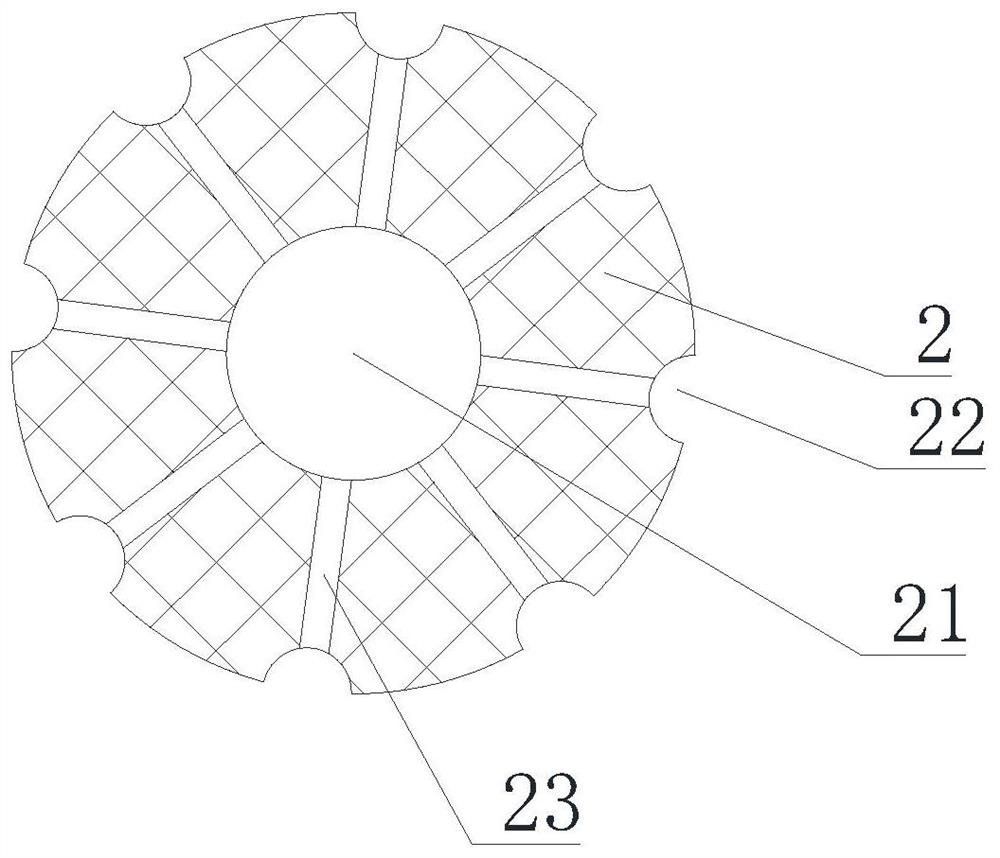

[0041] S2: Blend modified antibacterial polyester fiber and viscose fiber at a ratio of 60 / 40 to obtain polyester viscose blended fiber; blend modified antibacterial polyester fiber and bamboo fiber at a ratio of 50 / 50 to obtain polyester Bamboo fiber blended fiber; blending modified antibacterial polyester fiber and tencel according to the ratio of 70 / 30 to obtain polyester tencel blended fiber; on the surface of polyester viscose blended fiber, polyester bamboo fiber blended fiber and Polyester Tencel blended fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com