A refrigerator door trim strip and its surface treatment method

A surface treatment and door trim technology, which is applied in the field of refrigerator door trim and its surface treatment, can solve the problems of unapplicable, low surface hardness and single color of refrigerator door trim, and achieve high hardness, high efficiency and various colors sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

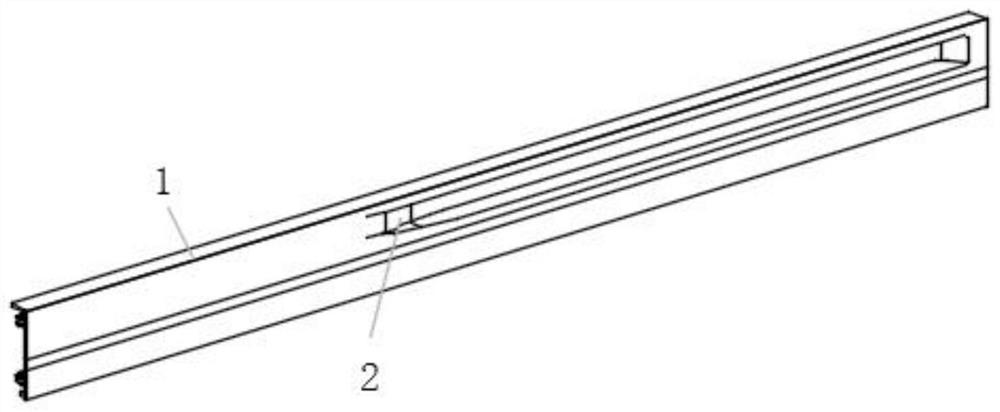

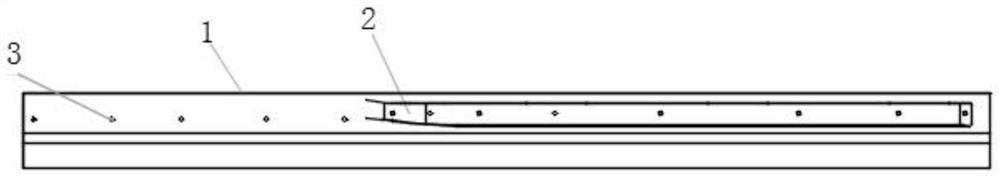

[0030] see Figure 1-2 As shown, the present invention is a refrigerator door trim, comprising: a door trim body 1; a rectangular groove is provided on the door trim body 1; a 3D special-shaped curved surface 2 is provided at the connection between the rectangular groove and a surface of the door trim body 1 ; A number of ventilation holes 3 are provided on the door trim body;

[0031] The surface of the door trim body 1 is sealed with a decorative film 4; the decorative film 4 sequentially includes a PET substrate, a UV layer, an ink layer, and an adhesive layer from inside to outside. Among them, the thickness of the PET substrate is 35um; the thickness of the UV layer is 7um, the thickness of the ink layer is 12um, the thickness of the adhesive layer is 10um; the diameter of the air hole is 0.4mm.

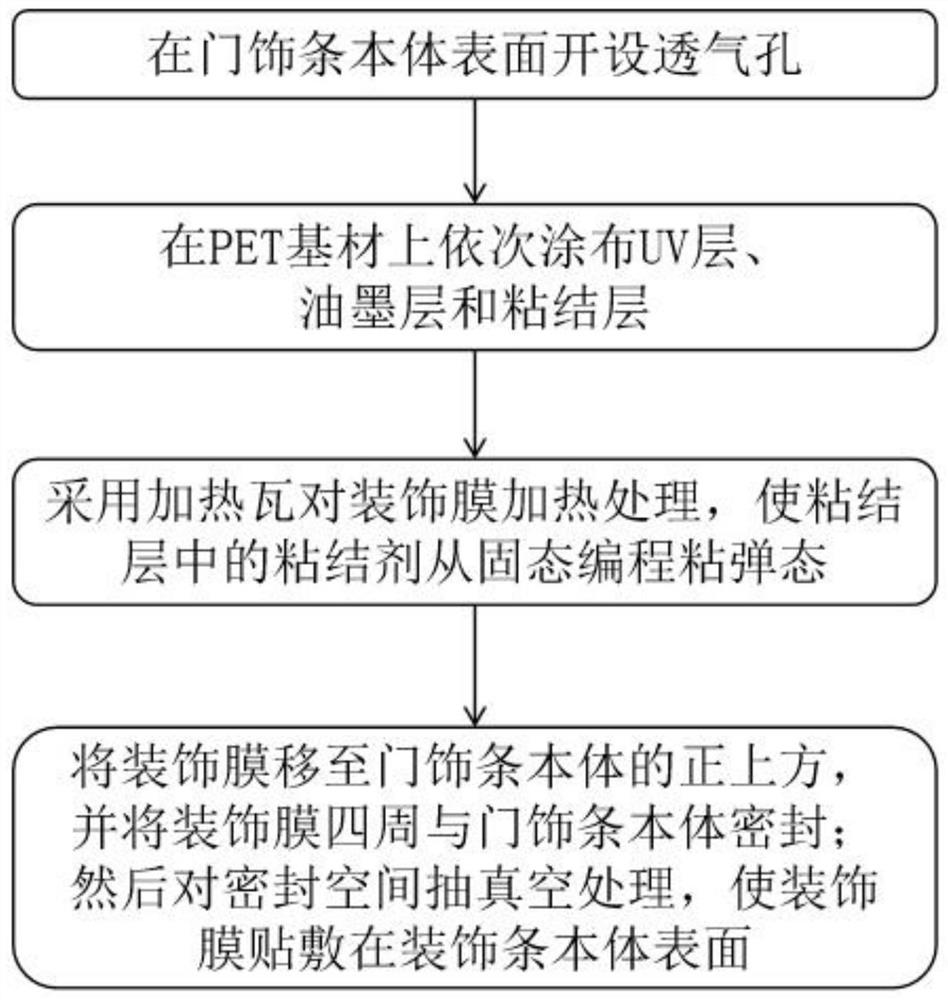

[0032] The surface treatment method of the refrigerator door trim strip of the present invention is as follows in the actual use process:

[0033] Step 1: Open air vents 4 on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com