Thermal insulation composite external wall panel suitable for industrial manufacturing and environment-protecting construction and manufacturing method thereof

A technology of thermal insulation composite and external wall panels, which is applied in the direction of manufacturing tools, layered products, building structures, etc., can solve problems such as cracking, uneven cooling and heating of walls, hollowing, etc., to prevent the formation of heat convection, excellent Thermal insulation performance, high tensile strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

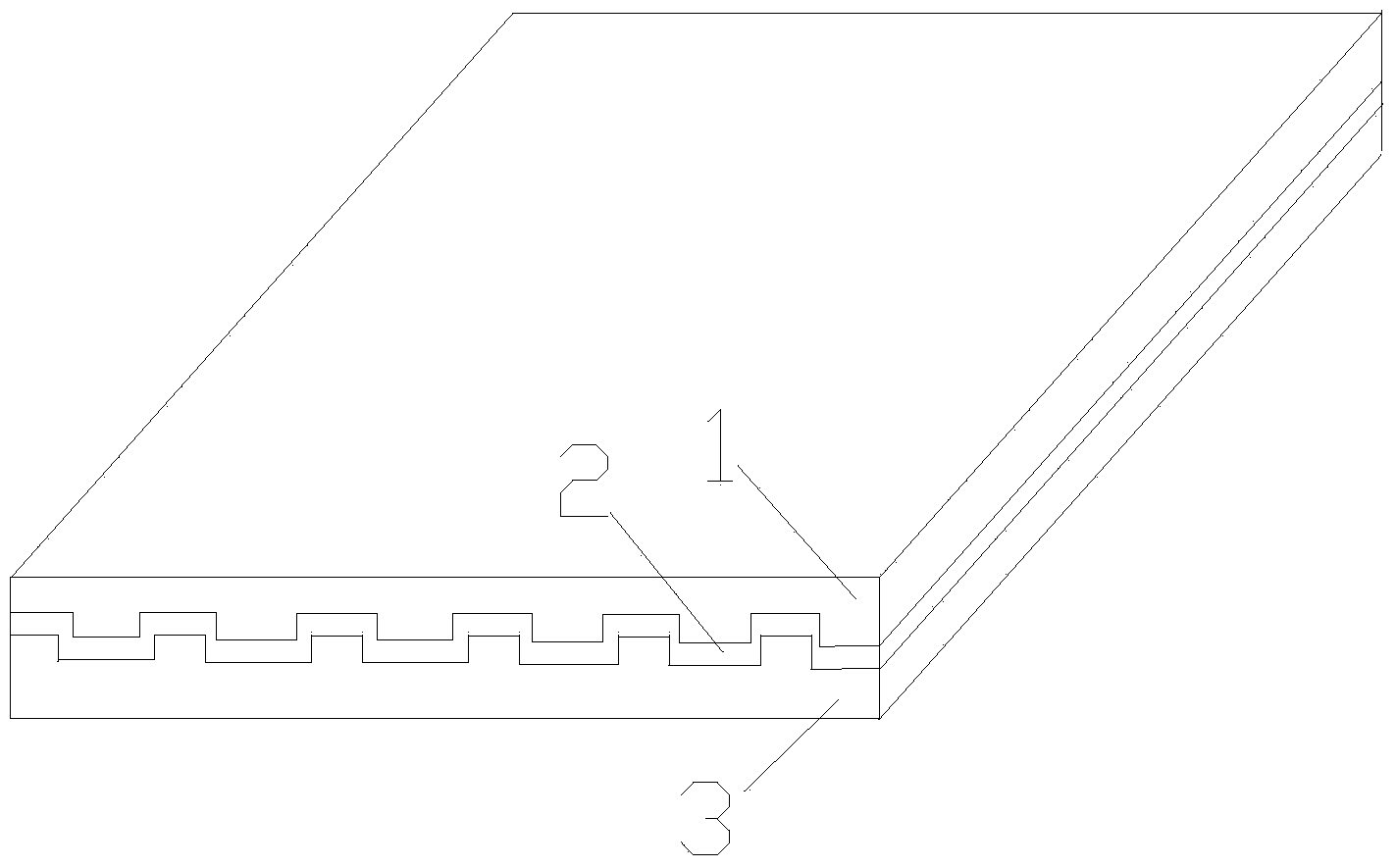

[0019] A thermal insulation composite exterior wall panel suitable for industrialized manufacturing and environmentally friendly construction with an air-decomposing absorbent, including a composite fiber pressure plate and a high-strength waterproof vermiculite substrate, and the composite fiber pressure plate and high waterproof vermiculite substrate are passed through an interlaced Grooves and protrusions are combined, and there is an energy-saving, heat-radiation-resistant, air-absorbing and decomposing adhesive layer between the composite fiber pressure plate and the high-water-proof vermiculite substrate.

[0020] Adopt multi-level and multi-step conditions to block heat radiation from passing through the composite board and prevent air heat convection at the junction, thereby greatly improving the thermal insulation performance and bonding strengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com