Solar cell back film with high weather resistance and high water vapor barrier property and preparation method of solar cell back film

A solar cell and water vapor barrier technology, applied in the field of solar cells, can solve problems such as yellowing, air bubbles, and electrode corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The present invention also provides a method for preparing a back film of a solar cell with high weather resistance and high water vapor barrier, comprising the following steps:

[0048] (1) Fix a weather-resistant metal film or a weather-resistant metal coating on one side of the support layer;

[0049] (2), fixing a weather-resistant polymer film or a weather-resistant polymer coating on the other side of the support layer;

[0050] (3), post-processing.

[0051] Wherein, the method also includes:

[0052] A weather-resistant coating for metal or a weather-resistant polymer film for metal is fixed on one side of the metal film or the weather-resistant metal coating.

[0053] Wherein, the adhesive is set, and the adhesive is left to stand or matured to fix the weather-resistant polymer film or the weather-resistant metal film on the support layer; One or any combination of coatings to fix the weather-resistant polymer coating on the support layer; through magnetron ...

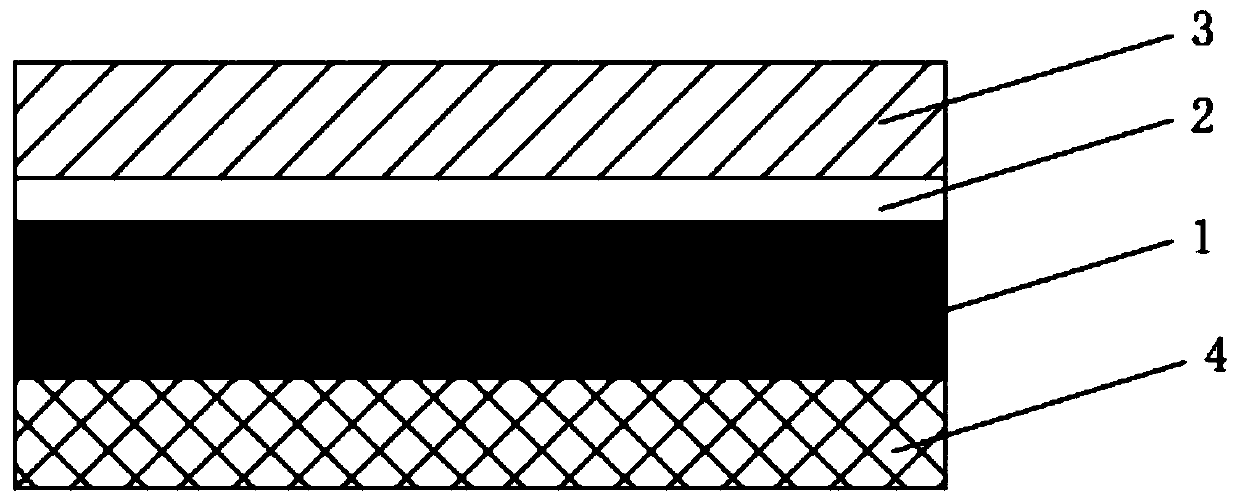

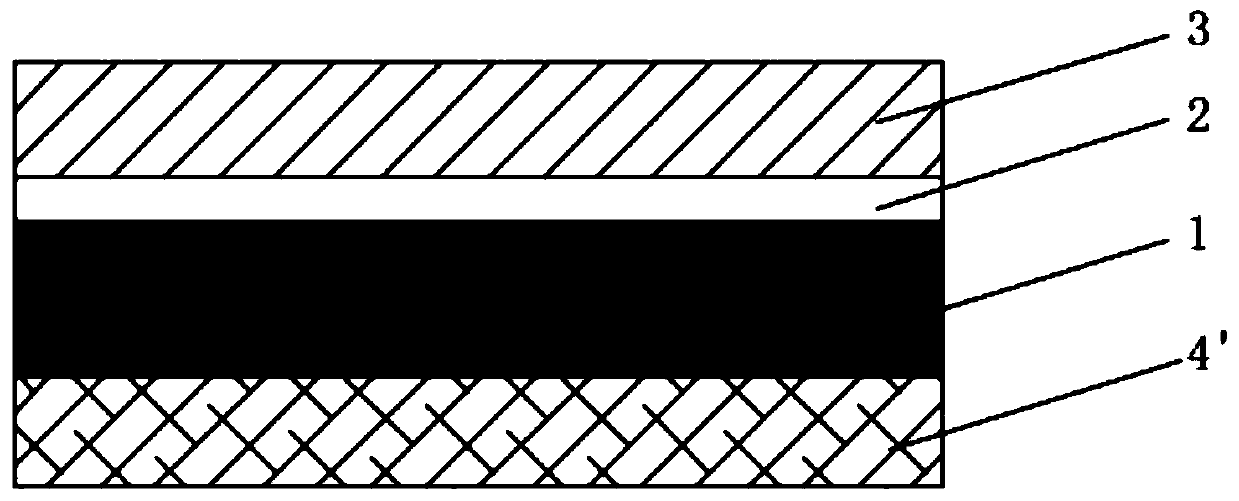

Embodiment 1

[0056] On one side of the support layer 1 with polyethylene terephthalate as the main material and a thickness of 250-300 μm, a layer of gold, silver, The weather-resistant metal film 2 with copper, iron and aluminum as the main material obtains the semi-finished product a1;

[0057] Place the semi-finished product a1 in a constant temperature environment of 40-80°C for 24-72 hours to obtain the semi-finished product a2;

[0058] One side of the metal film 2 of the semi-finished product a2 is coated with a thickness of 15-20 μm by roller coating, and modified polytetrafluoroethylene resin, modified polytetrafluoroethylene alkoxy resin, modified ethylene-tetrafluoroethylene The mixture of copolymer resin, modified fluoroolefin-vinyl ether copolymer resin, modified weather-resistant polyester and modified polyacrylic resin is a reactive polymer with curable groups as the main body, adding specific metal adhesion promotion The weather-resistant coating 3 for metals prepared with...

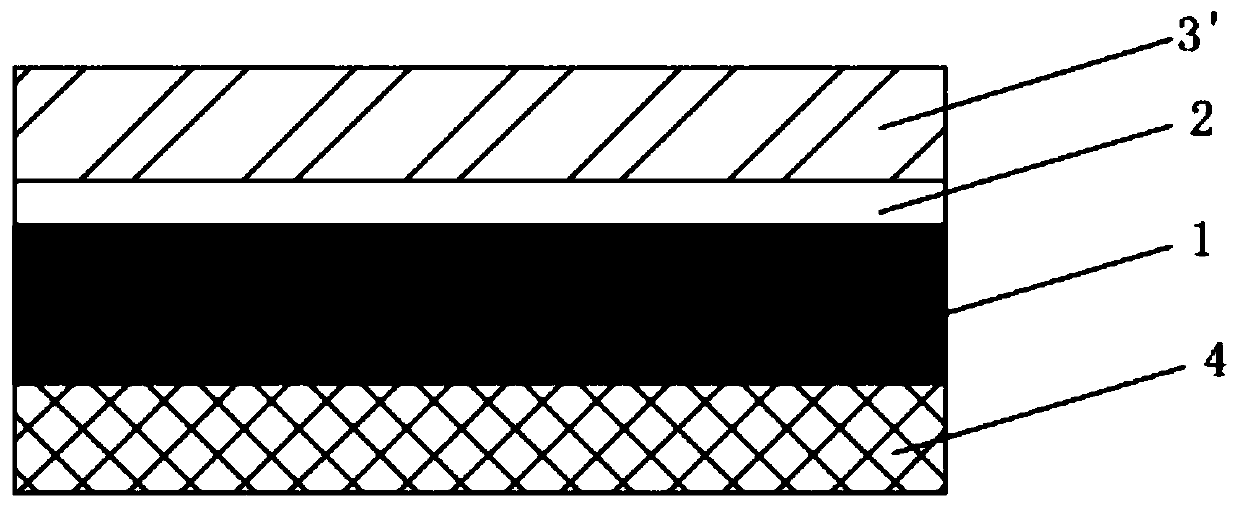

Embodiment 2

[0062] On one side of the support layer 1 with polyethylene terephthalate as the main material and a thickness of 250-300 μm, a layer of gold, silver, The weather-resistant metal film 2 with copper, iron and aluminum as the main material obtains the semi-finished product a1;

[0063] On one side of the metal film 2 of the semi-finished product a1, fix a layer of weather-resistant polymer film 3' for metal with a thickness of 20-38 μm and made of polyvinyl fluoride or polyvinylidene fluoride as the main material by adhesive bonding. , get the semi-finished product a2;

[0064] Place the semi-finished product a2 in a constant temperature environment of 40-80°C for 24-72 hours to obtain the semi-finished product b;

[0065] On the untreated side of the support layer 1 of the semi-finished product b, a layer of thickness of 10-15 μm is coated by roller coating, and modified polytetrafluoroethylene resin, modified polytetrafluoroethylene alkoxy resin, modified ethylene-tetrafluoro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com