Preparation method of self-lubricating novel material for lock cylinder

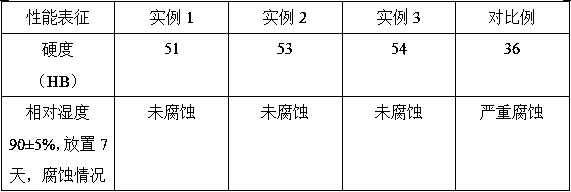

A self-lubricating, new material technology, applied in the coating process of metal materials, devices for coating liquid on the surface, coatings, etc., can solve the problems of low hardness, large rotational friction resistance of the lock cylinder, and easy rust of the lock cylinder. , to achieve the effect of high hardness, reducing scratch damage and increasing self-lubricating ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Take 80~160g of copper powder, 20~40g of iron powder, 4~8g of chromium powder, 5~10g of ferrochrome powder, 2~4g of silicon dioxide and 20~40g of engine oil and fully mix them in the mixing equipment to obtain the mixture. The mixture is cold-pressed to obtain the lock cylinder matrix; take 10-20g of zinc phosphate and place it in 150-300g of 13mol / L ammonia solution, stir until dissolved, and obtain the modified solution; put the lock cylinder matrix into the modified solution , take it out after 1h, and dry to obtain the modified lock core matrix; take 2~4g of graphite and 1~2g of anhydrous sodium nitrate and pour it into 35~70g18mol / L sulfuric acid solution under ice-water bath conditions, add 8~ 16g of potassium permanganate, stirred at 30°C for 1 hour to obtain mixed solution A; add 50~100g of deionized water to the mixed solution and continue to stir for 30min, control the temperature at 90°C, add 20~40g of 10mol / L hydrogen peroxide solution, Obtain the mixed solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com