PVC chemical leather treating agent, PVC chemical leather and method for producing the same

A technology of synthetic leather and treatment agent, applied in fiber processing, textiles and papermaking, etc., can solve the problems of surface layer damage of synthetic leather, surface damage of synthetic leather, change of haze, etc., and achieves easy cleaning, good weather resistance, and easy cleaning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Take 30 kg of melamine resin, 10 kg of polyurethane resin, 30 kg of methyl isobutyl ketone, 4 kg of tetrahydrofuran, and 3 kg of p-toluenesulfonic acid. Stir and mix the melamine resin, polyurethane resin, methyl isobutyl ketone and tetrahydrofuran evenly, and then seal and pack for use.

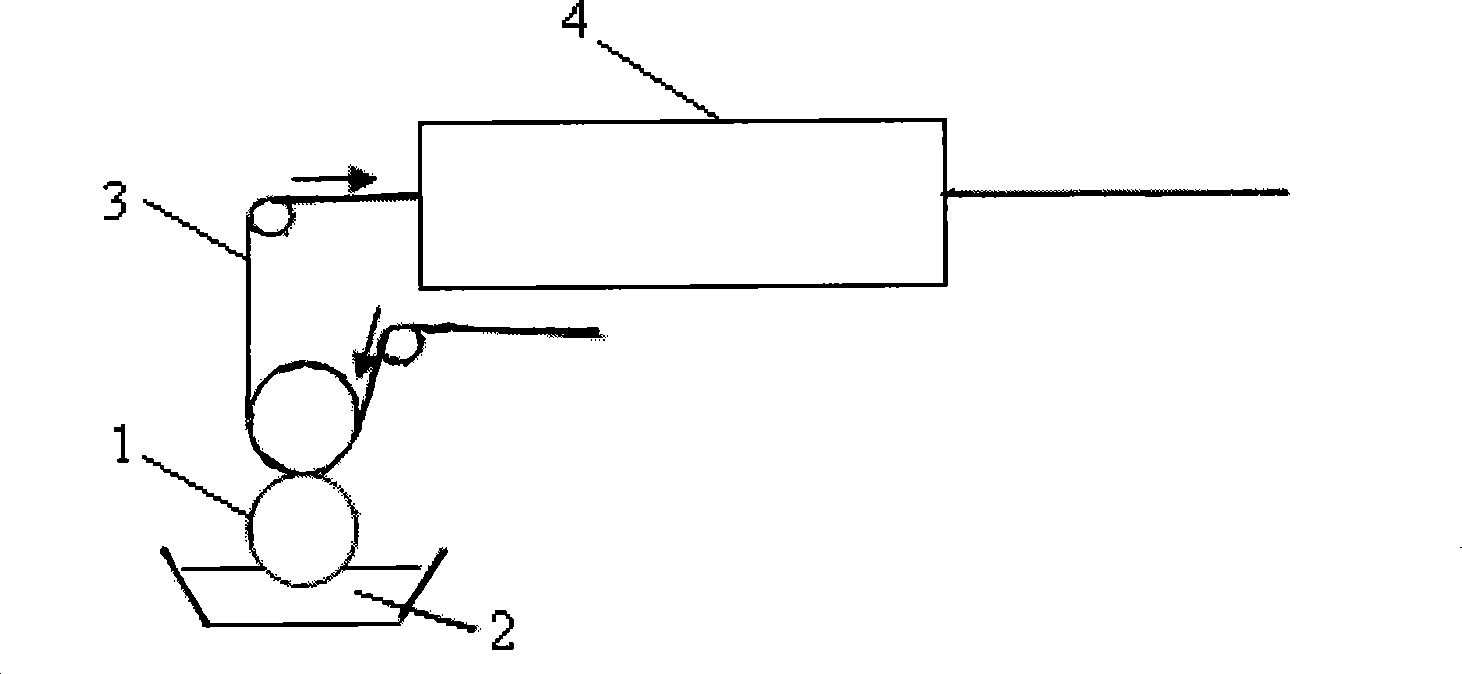

[0029] Before use, add p-toluenesulfonic acid and stir evenly to obtain a PVC synthetic leather treatment agent. Such as figure 1 As shown, the treatment wheel 1 with 100-120 mesh is selected, and the PVC synthetic leather treatment agent 2 is covered on the surface of the PVC synthetic leather 3 by gravure printing. The amount of PVC synthetic leather treatment agent 2 on the surface of PVC synthetic leather is 10-20g / m 2 . Then it is dried in an oven 4 at a drying temperature of 130° C. and a drying time of 1 min.

Embodiment 2

[0031] Get 40kg of melamine resin, 20kg of polyurethane resin, 40kg of methyl isobutyl ketone, 8kg of tetrahydrofuran, 10kg of silicon dioxide, and 8kg of p-toluenesulfonic acid. Stir and mix the melamine resin, polyurethane resin, methyl isobutyl ketone and tetrahydrofuran evenly, then add silicon dioxide and stir again, and then seal and pack for use.

[0032] Before use, add p-toluenesulfonic acid and stir evenly to obtain a PVC synthetic leather treatment agent. Such as figure 1 As shown, the treatment wheel 1 with 100-120 mesh is selected, and the PVC synthetic leather treatment agent 2 is covered on the surface of the PVC synthetic leather 3 by gravure printing. The amount of PVC synthetic leather treatment agent 2 on the surface of PVC synthetic leather is 10-20g / m 2 . Then it is dried in an oven 4 at a drying temperature of 130° C. and a drying time of 1 min.

Embodiment 3

[0034] Get 35kg of melamine resin, 15kg of polyurethane resin, 35kg of methyl isobutyl ketone, 6kg of tetrahydrofuran, 5kg of silicon dioxide, and 5kg of p-toluenesulfonic acid. Stir and mix the melamine resin, polyurethane resin, methyl isobutyl ketone and tetrahydrofuran evenly, then add silicon dioxide and stir again, and then seal and pack for use.

[0035] Before use, add p-toluenesulfonic acid and stir evenly to obtain a PVC synthetic leather treatment agent. Such as figure 1 As shown, the treatment wheel 1 with 100-120 mesh is selected, and the synthetic leather treatment agent 2 is covered on the surface of the PVC synthetic leather 3 by gravure printing. The amount of PVC synthetic leather treatment agent 2 on the surface of PVC synthetic leather is 10-20g / m 2 . Then it is dried in an oven 4 at a drying temperature of 130° C. and a drying time of 1 min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com