Scratch-resistant wear-resistant stone-plastic composite floor

A composite floor and stone-plastic technology, applied in the field of floor manufacturing, can solve the problems of easy scratches, warping and deformation of the board shape, and high comprehensive cost, and achieve the effects of avoiding warping and arching, appropriate thermal expansion coefficient, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

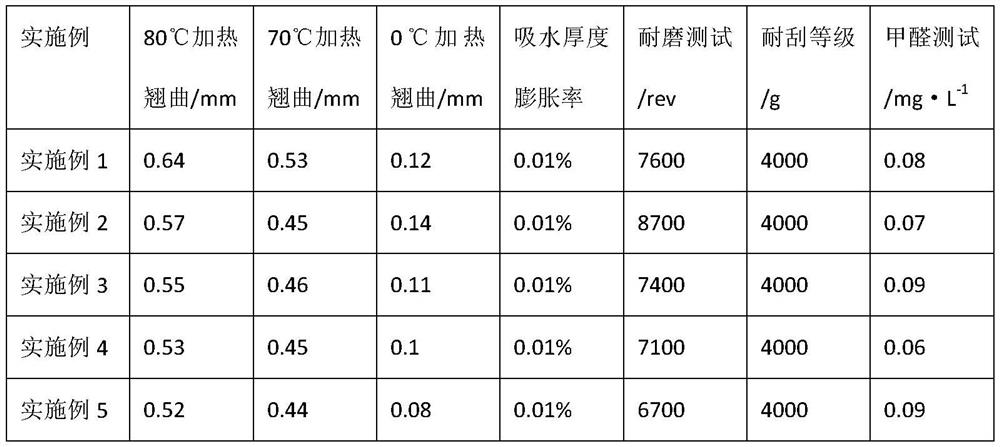

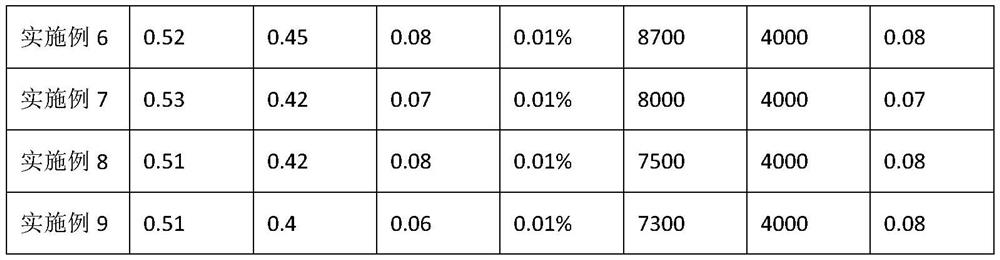

Examples

Embodiment 1

[0028] Example 1: A scratch-resistant and wear-resistant stone-plastic composite floor, including from top to bottom, impregnated paper, flexible middle layer, PVC color film paper, energy-absorbing layer A, stone-plastic substrate board, energy-absorbing layer B ; The mass ratio of PVC powder and calcium powder in the stone-plastic substrate board is 1:2.5~1:3.5.

[0029] Its preparation method comprises the following steps:

[0030] Preparation of S1 base material: The stone-plastic base plate is produced by a twin-screw extruder. The thickness of the stone-plastic base plate is 3.5 mm. The properties of the produced base material meet the following conditions: static bending strength > 20Mpa, elastic modulus > 4000Mpa, base material dimensional change rate < 0.1% in oven test at 80°C for 6 hours; use a screw extruder and prepare according to the normal production process of stone-plastic flooring Stone plastic substrate;

[0031] S2. Preparation of the flexible middle lay...

Embodiment 2

[0035] Example 2: A scratch-resistant and wear-resistant stone-plastic composite floor, which includes, from top to bottom, rubber-impregnated paper, a flexible middle layer, PVC color film paper, energy-absorbing layer A, stone-plastic substrate board, and energy-absorbing layer B ; The mass ratio of PVC powder and calcium powder in the stone-plastic substrate board is 1:3.5.

[0036] Its preparation method comprises the following steps:

[0037] Preparation of S1 base material: the stone-plastic base plate is produced by a twin-screw extruder. The thickness of the stone-plastic base plate is 5mm. The mass ratio of PVC powder and calcium powder in the base material formula is 1:3.5. The performance of the base material meets the following conditions: static bending strength > 20Mpa, elastic modulus > 4000Mpa, and the dimensional change rate of the base material in an oven test at 80°C for 6 hours < 0.1%; use a screw extruder to prepare stone according to the normal production...

Embodiment 3

[0042] Example 3: A scratch-resistant and wear-resistant stone-plastic composite floor, including from top to bottom, impregnated paper, flexible middle layer, PVC color film paper, energy-absorbing layer A, stone-plastic substrate board, and energy-absorbing layer B ; The mass ratio of PVC powder and calcium powder in the stone-plastic substrate board is 1:2.5.

[0043] Its preparation method comprises the following steps:

[0044] Preparation of S1 base material: The stone-plastic base plate is produced by a twin-screw extruder. The thickness of the stone-plastic base plate is 3.5mm. The properties of the produced base material meet the following conditions: static bending strength > 20Mpa, elastic modulus > 4000Mpa, base material dimensional change rate < 0.1% in the oven test at 80°C for 6 hours; use a screw extruder and prepare according to the normal production process of stone-plastic flooring Stone plastic substrate;

[0045] S2. Preparation of the flexible middle la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com