A scratch-resistant and wear-resistant stone-plastic composite floor

A composite floor and stone-plastic technology, which is applied in the field of floor manufacturing, can solve the problems of plate warping, easy scratches, and high overall cost, and achieve the effects of appropriate thermal expansion coefficient, avoiding warping and arching, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

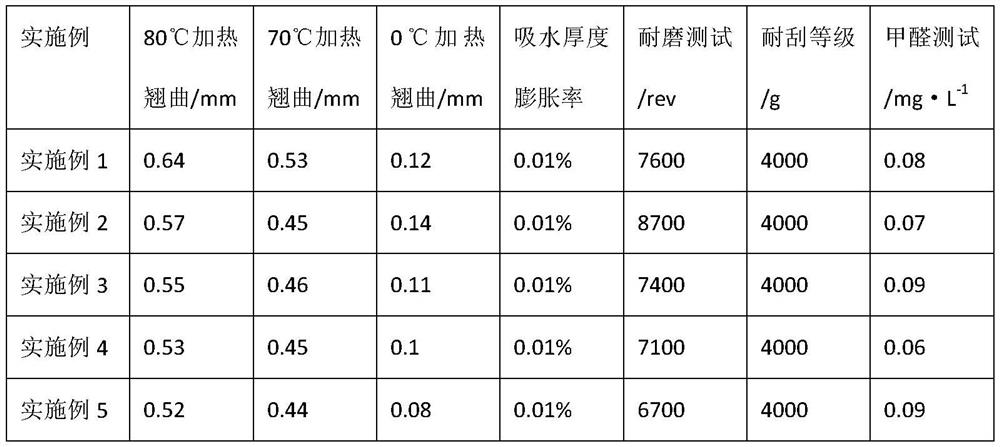

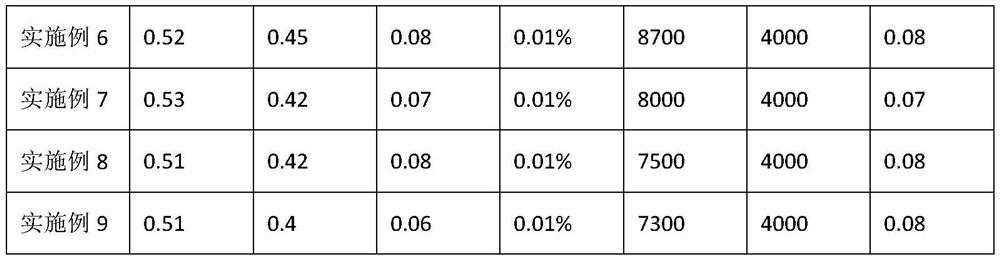

Examples

Embodiment 1

[0028] Example 1: A scratch-resistant abrasion-resistant stone-plastic composite floor, from top to bottom, including, dipping paper, flexible intermediate layer, PVC color film paper, suction layer A, a stone plastic substrate plate, an capability layer B The mass ratio of PVC powder and calcium powder in the stone-plastic substrate plate is 1: 2.5 to 1: 3.5.

[0029] Its preparation method includes the following steps:

[0030] Preparation of S1 substrate: Production of stone-plastic substrate plate by twin-screw extruder, the thickness of the stone plastic substrate plate is 3.5 mm, the mass ratio of the mixing of PVC powder and calcium powder in the substrate formulation is 1: 3, squeezed The substrate performance satisfies the following conditions: static strength> 20MPa, elastic modulus> 4000MPa, substrate 80 ° C 6 hour oven test size change rate <0.1%; use screw extruder, according to the normal production process of stone plastic floor Stone plastic substrate;

[0031] S2....

Embodiment 2

[0035] Example 2: A scratch-resistant abrasion-resistant composite floor, in order from top to bottom, including, immersion paper, flexible intermediate layer, PVC color film paper, suction layer A, a stone plastic substrate plate, a capability layer B The mass ratio of PVC powder and calcium powder in the stone plastic substrate plate was 1: 3.5.

[0036] Its preparation method includes the following steps:

[0037] Preparation of the S1 substrate: Production of the stone plastic substrate plate by twin screw extruder, the thickness of the stone-plastic substrate plate is 5mm, the mass ratio of the mixing of PVC powder and calcium powder in the substrate formulation is 1: 3.5, extruded The substrate performance satisfies the following conditions: static intensity> 20MPa, elastic modulus> 4000MPa, substrate 80 ° C 6 hour oven test size change rate <0.1%; use screw extruder, according to the normal production process of stone plastic floor Plastic substrate;

[0038] S2. Preparatio...

Embodiment 3

[0042] Example 3: A scratch resistant abrasion-resistant composite floor, in order from top to bottom, including, dipping paper, flexible intermediate layer, PVC color film, suction layer A, a stone-plastic substrate plate, a capability layer B The mass ratio of PVC powder and calcium powder in the stone plastic substrate plate was 1: 2.5.

[0043] Its preparation method includes the following steps:

[0044] Preparation of S1 substrate: Production of stone-plastic substrate plate by twin screw extruder, the thickness of the stone plastic substrate plate is 3.5 mm, the mass ratio of the mixing of PVC powder and calcium powder in the substrate formulation is 1: 2.5, squeezed The substrate performance satisfies the following conditions: static strength> 20MPa, elastic modulus> 4000MPa, substrate 80 ° C 6 hour oven test size change rate <0.1%; use screw extruder, according to the normal production process of stone plastic floor Stone plastic substrate;

[0045] S2. Preparation of fle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com