Single-component water-based epoxy anticorrosive primer and preparation method thereof

A water-based epoxy and anti-corrosion primer technology, applied in anti-corrosion coatings, coatings, etc., can solve problems such as poor impact resistance, poor weather resistance, and paint waste, achieve good water resistance and anti-corrosion performance, and solve brittleness and weather resistance. The effect of expanding the range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

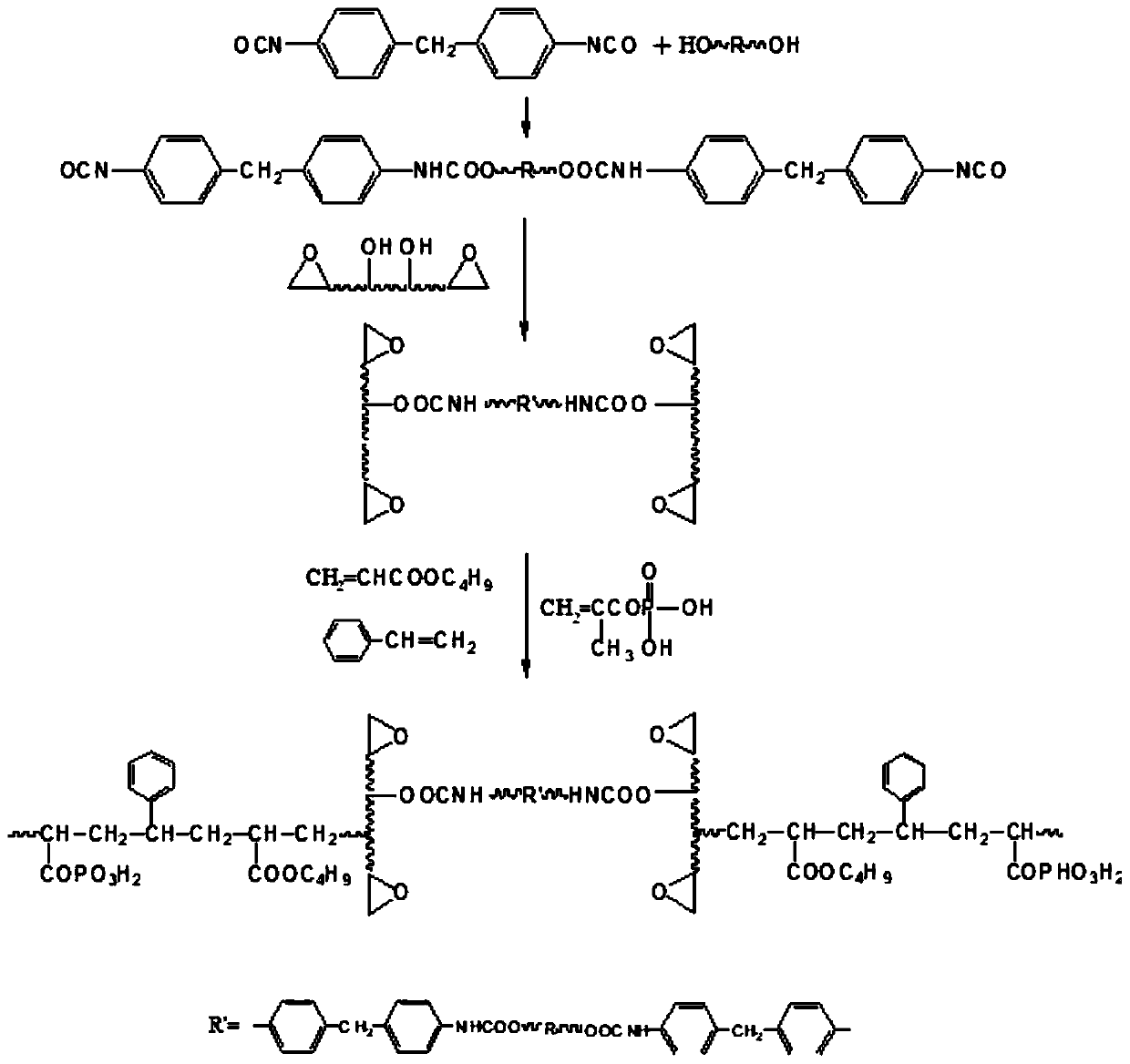

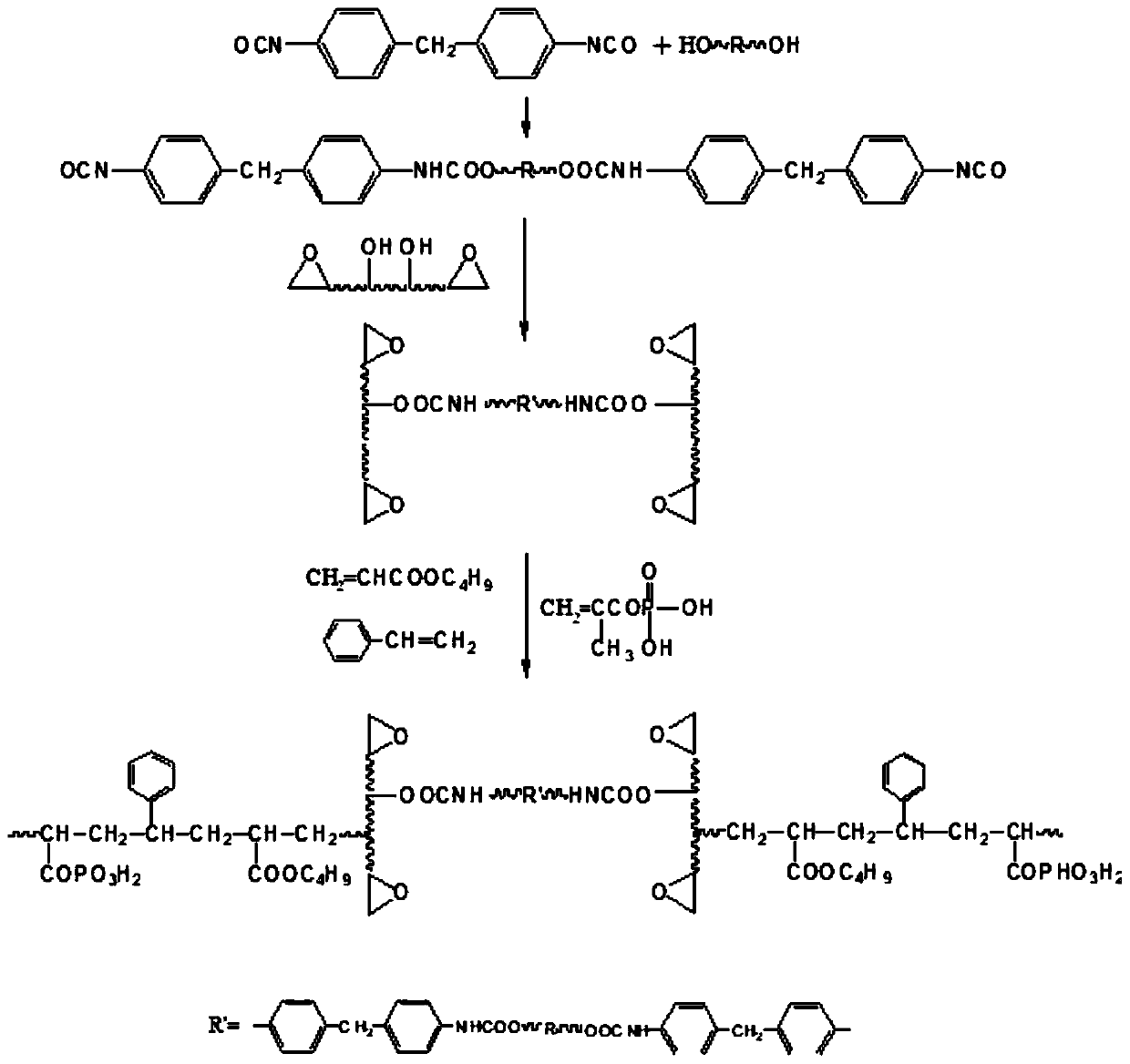

Method used

Image

Examples

Embodiment 1

[0054] A kind of one-component waterborne epoxy anticorrosion primer, raw material comprises by weight:

[0055] Water-based polyurethane epoxy acrylate emulsion 40-60%, dispersant BYK-151 1.5%, defoamer BYK02 51%, substrate wetting agent TEGO Wet 250 0.2%, anti-rust pigment iron oxide yellow 15%, anti-flash embroidery agent R-760F 2%, thickener RM-8W 1%, filler light calcium carbonate 9%, and the rest is deionized water.

[0056] Wherein the raw material of aqueous polyurethane epoxy acrylate emulsion comprises by weight:

[0057] Bisphenol A type epoxy resin E-44 35%, diisocyanate liquefied MDI 15%, polyethylene glycol 2000 18%, styrene 22%, ammonium persulfate 7%, sodium carbonate 0.5%, and the rest is deionized water.

Embodiment 2

[0059] A kind of one-component waterborne epoxy anticorrosion primer, raw material comprises by weight:

[0060] Waterborne polyurethane epoxy acrylate emulsion 60%, dispersant TEGO Dispers 715W 1.7%, defoamer BYK-023 0.5%, substrate wetting agent TEGO Wet 245 0.5%, mica powder 13%, anti-flash agent Raybo 60 0.5 %, thickener RM-8W 3.4%, filler calcite powder 15%, and the rest is deionized water.

[0061] Wherein the raw material of aqueous polyurethane epoxy acrylate emulsion comprises by weight:

[0062] Bisphenol A type epoxy resin E-20 30%, diisocyanate liquefied HDI 11%, polyethylene glycol 1000 25%, hydroxypropyl acrylate 20%, BPO 3%, sodium carbonate 0.8%, and the rest is deionized water.

Embodiment 3

[0064] A kind of one-component waterborne epoxy anticorrosion primer, raw material comprises by weight:

[0065] Water-based polyurethane epoxy acrylate emulsion 40%, dispersant BYK-190 1.6%, defoamer TEGO Airex931 1.3%, substrate wetting agent BYK-301 0.1%, glass flake 12%, anti-flash agent Raybo 60 3%, Thickener TEGO ViscoPlus 3060 1.9%, filler talc 8%, the rest is deionized water.

[0066] Wherein the raw material of aqueous polyurethane epoxy acrylate emulsion comprises by weight:

[0067] Bisphenol A type epoxy resin E-51 32%, diisocyanate liquefied IPDI 10%, polyethylene glycol 6000 21%, hydroxypropyl acrylate 28%, potassium persulfate 4%, sodium bicarbonate 1%, the rest is to ionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com