ASA 3D printing wire with low warpage at low temperature and preparation method thereof

A printing wire, low warpage technology, applied in the direction of additive processing, etc., can solve the problems of interlayer stress cracking, cracked material toughness, reduce nozzle life and other problems, achieve the effect of reducing energy consumption, excellent molding performance, and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

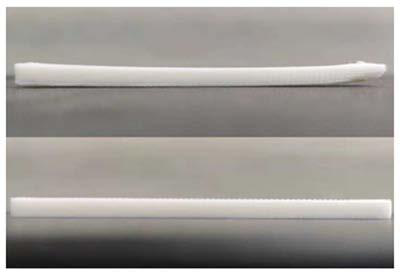

Image

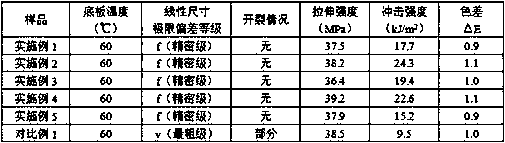

Examples

Embodiment 1

[0035] A low-temperature and low-warpage ASA 3D printing wire, the components are: ASA resin 60%, wherein the content of acrylate rubber in ASA resin is 42%, EMA-aramid pulp compound 25%, Solvent (E-BA-GMA) 8%, terpene resin 5%, 1010 antioxidant 1%, paraffin oil 1%.

[0036] Its preparation method comprises the following steps:

[0037] A. EMA and aramid pulp are vacuum-dried respectively;

[0038] B. Accurately weigh the EMA and aramid pulp dried in step A according to a mass ratio of 1:1, then place the weighed components in a high-speed kneader and mix them uniformly to obtain a mixture;

[0039] C. Mix the mixture in step B with a continuous mixer to obtain an EMA-aramid pulp compound. The mixing temperature is 95° C., the extrusion temperature is 150° C., and the screw speed is 40 rpm.

[0040] D. ASA, EMA-aramid pulp compound, E-BA-GMA, terpene resin and antioxidant 1010 are vacuum-dried respectively;

[0041] E. Accurately weigh the various resins and paraffin oil af...

Embodiment 2

[0046] A low-temperature and low-warpage ASA 3D printing wire, the components are calculated by weight percentage: ASA resin 65% (of which acrylate rubber content in ASA resin is 55%), TPU-aramid pulp compound 24.5%, benzene Ethylene-acrylonitrile-glycidyl methacrylate (SAG) 6%, tackifier C5 petroleum resin 3%, 168 antioxidant 0.5%, paraffin oil 1.0%.

[0047] Its preparation method comprises the following steps:

[0048] A. Vacuum dry the TPU and aramid pulp respectively;

[0049] B. Accurately weigh the TPU and aramid pulp dried in step A according to the mass ratio of 0.8:1, then place the weighed components in a high-speed kneader and mix them uniformly to obtain a mixture;

[0050] C. Mix the mixture in step B with a continuous mixer to obtain a TPU-aramid pulp compound. The mixing temperature is 100° C., the extrusion temperature is 160° C., and the screw speed is 42 rpm.

[0051] D. ASA, TPU-aramid pulp compound, SAG, C5 resin and 168 antioxidant are vacuum-dried resp...

Embodiment 3

[0057] A low temperature and low warpage ASA 3D printing wire, the components are calculated by weight percentage: ASA resin 55.7% (the content of acrylate rubber in ASA resin is 42%), EEA-aramid pulp compound 32, SGMA 7, Rosin resin 4, 1076 antioxidant 0.5, paraffin oil 0.8.

[0058] Its preparation method comprises the following steps:

[0059] A. EEA and aramid pulp are vacuum-dried respectively;

[0060] B. Accurately weigh the EEA and aramid pulp dried in step A according to the mass ratio of 2.5:1, then place the weighed components in a high-speed kneader and mix them uniformly to obtain a mixture;

[0061] C. Mix the mixture in step B with a continuous mixer to obtain the EEA-aramid pulp compound. The mixing temperature is 95° C., the extrusion temperature is 165° C., and the screw speed is 55 rpm.

[0062] D. ASA resin, EEA-aramid pulp compound, SGMA, rosin resin and antioxidant 1076 are vacuum-dried respectively;

[0063] E. Accurately weigh the various resins and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com