Preparation method of anticorrosion coiled steel pipe for marine environment

A technology for rolling steel pipes and marine environment, applied in the field of steel pipe manufacturing and processing, can solve problems such as poor corrosion resistance, short validity period, easy aging, etc., and achieve the effect of solving short validity period and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for preparing a corrosion-resistant rolled steel pipe for marine environments, comprising the following steps:

[0024] (1) Plate detection: through ultrasonic non-destructive testing of steel plates;

[0025] (2) Blank cutting and beveling;

[0026] (3) Rolling: The polished steel plate is rolled into an "O" shape by using the supporting rolling technology; Cantilever with bearings, the cantilever rotates freely on the inner wall of the pile pipe during the rolling process, which has reached the top support function and guaranteed the ellipticity of the steel pipe.

[0027] (4) UT flaw detection for group alignment, circle calibration, and longitudinal seam;

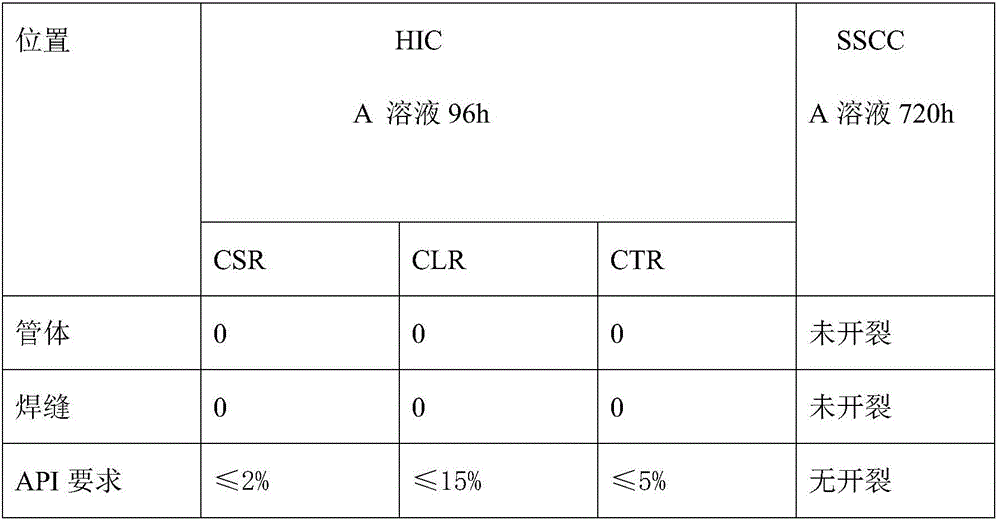

[0028] (5) Internal and external welding of longitudinal seams: internal welding adopts double-wire tandem submerged arc automatic welding, the first wire is DC, the current is 825A, and the voltage is 31V; the second wire is AC, the current is 400A, and the voltage is 34V; the distance between welding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com