Preparation method of antibacterial metal-organic framework membrane

A technology of organic framework and antibacterial metal, which is applied in the field of preparation of metal-organic framework membranes, can solve the problems of unstable membrane structure, cumbersome preparation steps, and poor repeatability, and achieve the effects of insufficient binding force, simple preparation process, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Step 1. Pretreatment of the vector. Take a clean piece of glass and put it into 10mL sulfuric acid and hydrogen peroxide mixed solution (volume ratio 7:3), react at 70°C for 2 hours, take it out, wash it with water, and dry it;

[0017] Step 2. Organic molecule modification carrier. Put the pretreated glass slide into 10mL of 3-aminopropyltriethoxysilane, react at 50°C for 24 hours, take it out, wash with methanol and water three times, and dry to obtain the modified carrier;

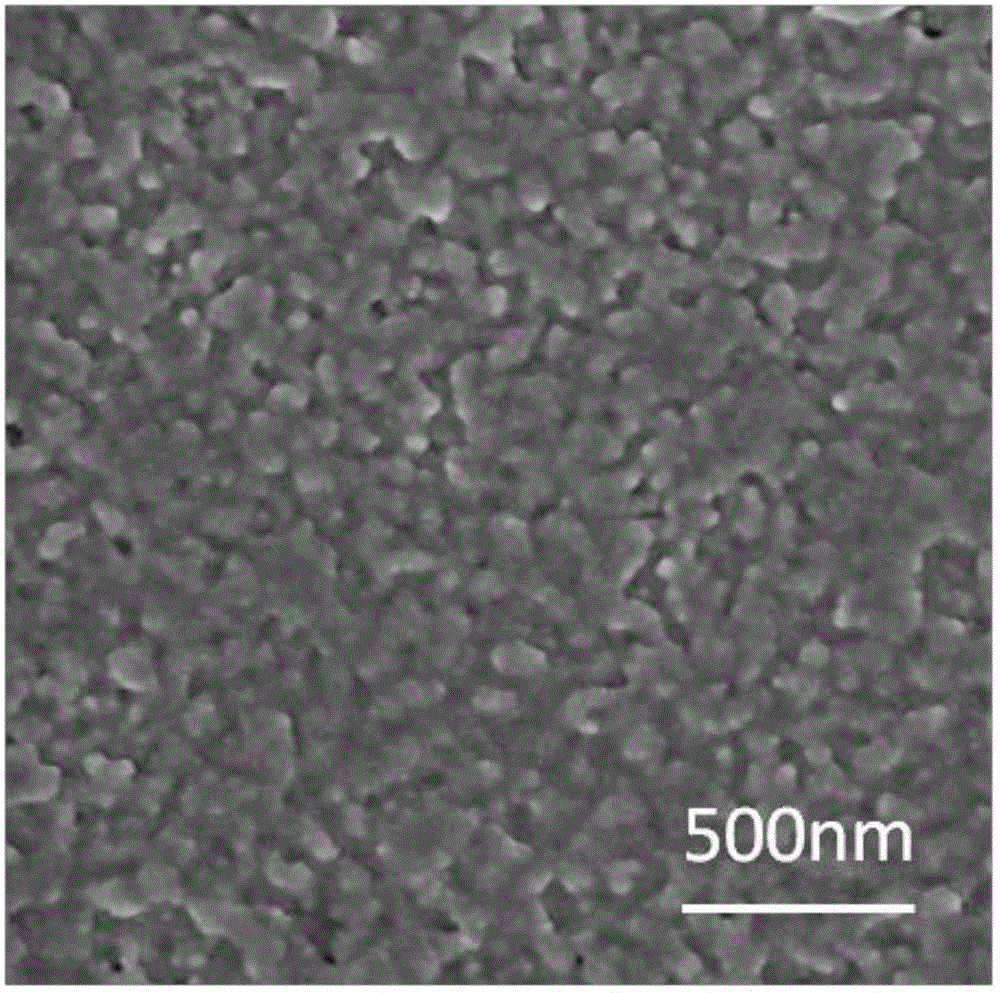

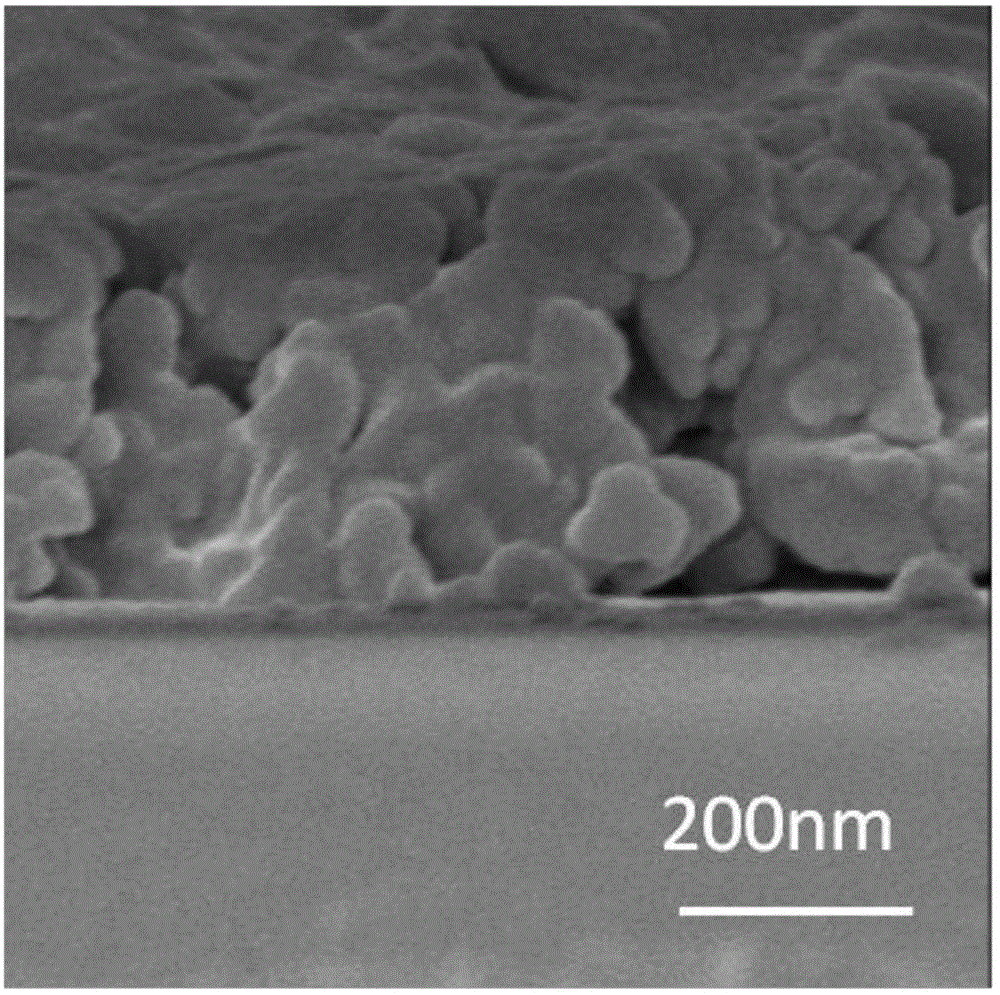

[0018] Step 3. Place the modified glass flake carrier in 10mL aqueous solution containing 0.2g trimesic acid, and transfer it to a 15mL polytetrafluorohydrothermal reaction kettle, crystallize at 180°C for 24 hours, cool naturally, and take out Place the glass flakes in 10mL aqueous solution containing 0.15g 1,3,5-benzenetricarboxylic acid and 0.15g silver nitrate, transfer the above mixed solution and glass flakes to a 15mL hydrothermal kettle, and react at 120°C for 72 hours, Cool naturally, ...

Embodiment 2

[0021] Step 1. Pretreatment of the vector. Take a clean single crystal silicon wafer and put it into 10mL sulfuric acid and hydrogen peroxide mixed solution (volume ratio 7:3), react at 80°C for 1 hour, take it out, wash it with water, and dry it;

[0022] Step 2. Organic molecule modification carrier. Put the pretreated single crystal silicon wafer into 10mL of 3-aminopropyltrimethylsilane, react at 70°C for 2 hours, take it out, wash with methanol and water three times, and dry to obtain the modified carrier;

[0023] Step 3. Place the modified silicon chip carrier in 10mL aqueous solution containing 0.2g of 5-nitroisophthalic acid, then transfer to a 15mL polytetrafluorohydrothermal reaction kettle, and crystallize at 120°C for 12 hours , cool naturally, take out the glass flakes and place them in 10mL aqueous solution containing 0.2g of 5-nitroisophthalic acid and 0.7g of silver nitrate, transfer the above mixed solution and glass flakes to a 15mL hydrothermal kettle, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com