Nanometer high temperature resistant thermal insulation and prevention coating

A technology of heat insulation and high temperature resistance, applied in the direction of coating, etc., can solve problems such as not very mature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

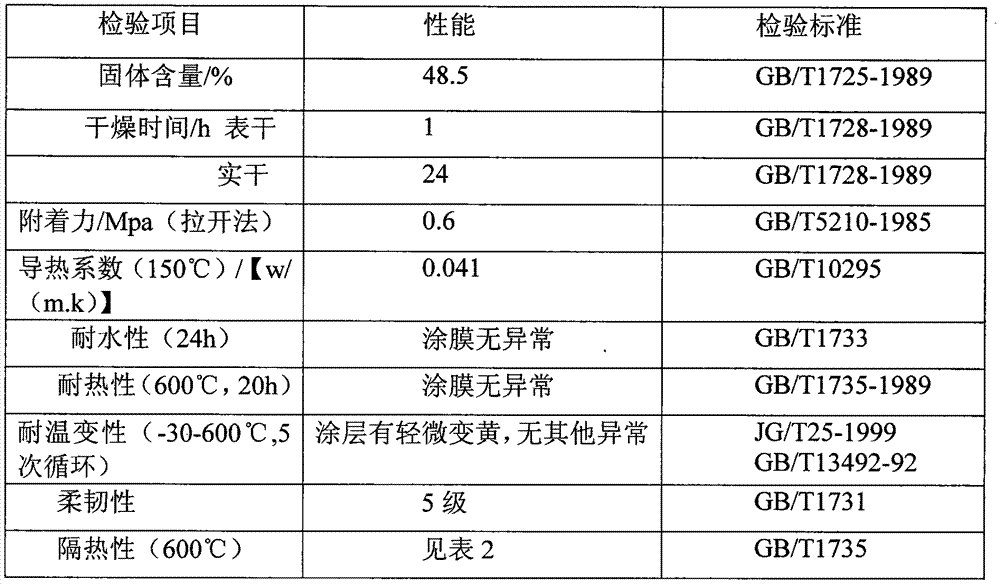

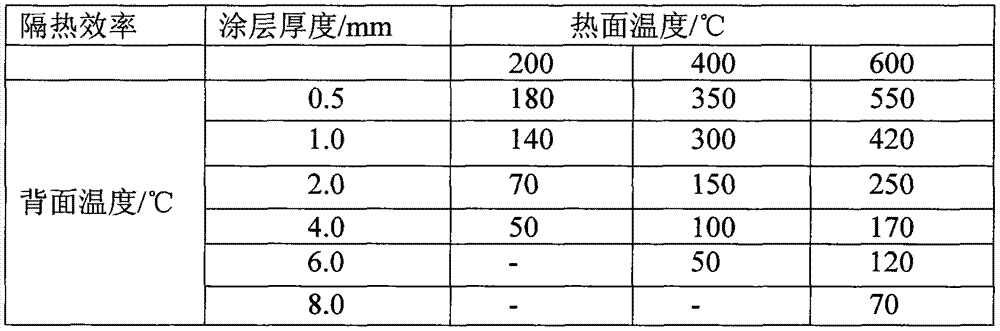

Examples

Embodiment Construction

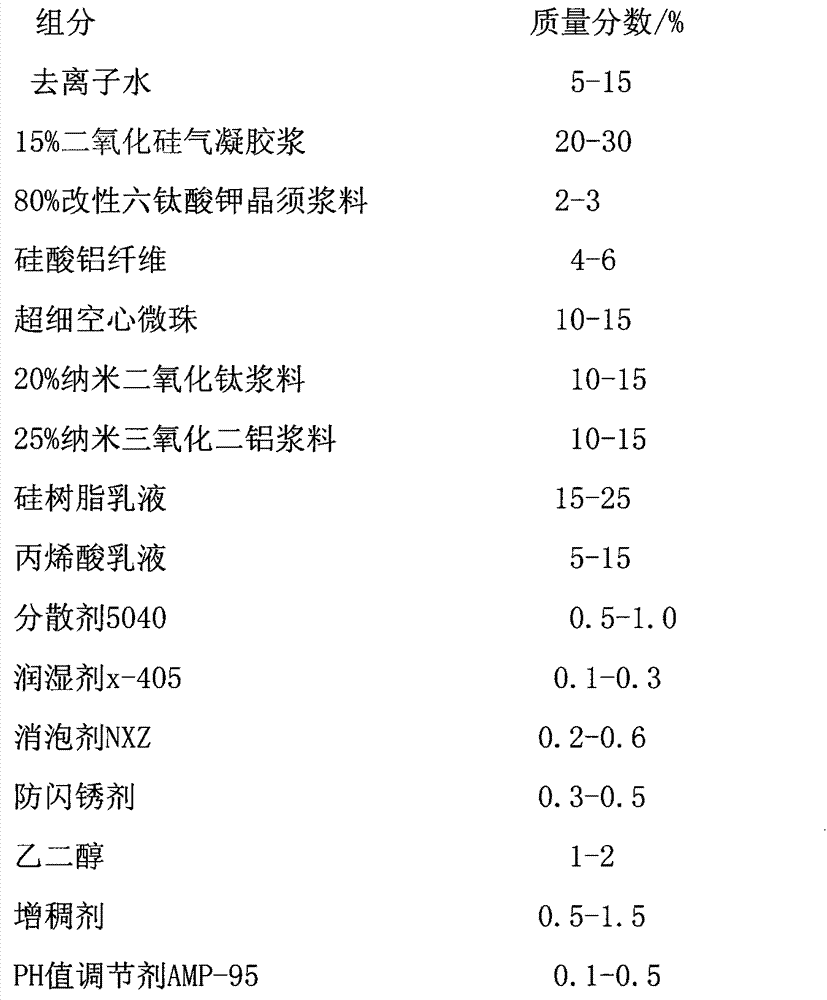

[0030] Describe the present invention in detail below in conjunction with specific embodiment: A kind of nano high temperature resistant thermal insulation coating, concrete formula is composed as follows:

[0031]

[0032]

[0033] The content units of the above-mentioned components are calculated by mass fraction.

[0034] The preparation process steps of nanometer high temperature resistant thermal insulation coating are as follows:

[0035] a. Preparation of modified potassium hexatitanate whisker slurry

[0036] Add 2 parts of silane coupling agent, 3 parts of dispersant, 0.4 part of wetting agent, 0.4 part of defoamer, and 2 parts of pH regulator into 15 parts of deionized water, stir well and add 80 parts of potassium hexatitanate whiskers , dispersed at high speed for 1 hour to make 80% potassium hexatitanate whisker slurry;

[0037] b. Preparation of silica airgel slurry

[0038] Add 2 parts of dispersant, 0.4 part of wetting agent, 0.4 part of defoamer, 1 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com