Rare-earth weather-proofing bridge steel plate with yield strength being 420MPa and production method of rare-earth weather-proofing bridge steel plate

A yield strength and rare earth technology, applied in the field of yield strength 420MPa grade rare earth weathering bridge steel plate and its production field, can solve problems such as increasing cost, and achieve the effects of short production cycle, low production cost and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Smelt according to the chemical composition shown in Table 1, and cast into a steel ingot. The steel ingot is heated to 1210°C for a total furnace time of 252 minutes. The first stage rolling is carried out on the experimental rolling mill, namely rolling in the austenite recrystallization zone. The start-rolling temperature is 1176℃, and the reduction in the first and second passes should be greater than 10%, and at least the reduction in the first and second passes should be controlled at 25% or more. When the thickness of the rolled piece is 45mm, wait on the roller table. The temperature reaches 930°C, and then the second stage rolling is carried out, namely rolling in the austenite non-recrystallized region. The final rolling temperature is 830°C, and the thickness of the finished steel sheet is 14mm. After rolling, the steel plate enters the laminar flow cooling device and is cooled to 630℃ at a rate of 10℃ / s, and finally the steel plate can be obtained.

Embodiment 2

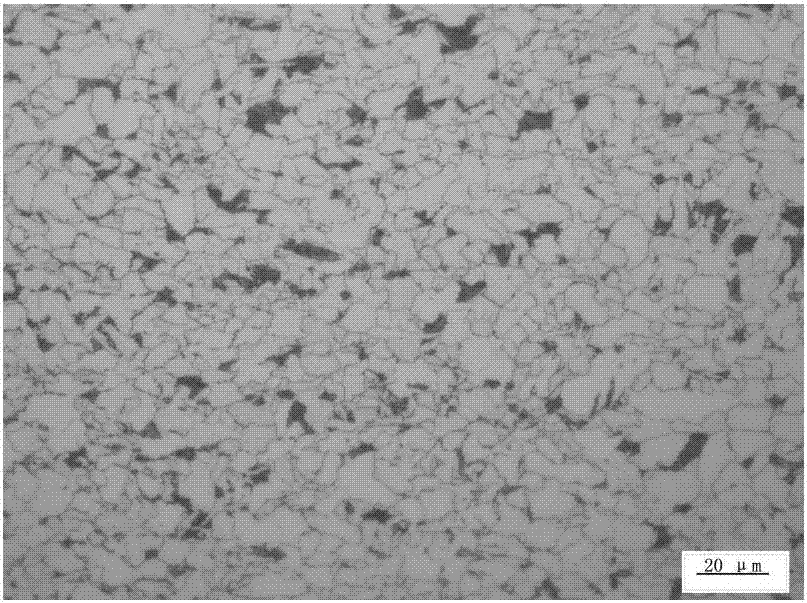

[0044] The implementation is the same as in Example 1, where the heating temperature is 1220℃, the total furnace time is 256 minutes, the opening temperature of the first stage rolling is 1175℃, the thickness of the intermediate billet is 60mm, and the opening temperature of the second stage rolling It is 925℃, the final rolling temperature is 836℃, and the thickness of the finished steel plate is 20mm. After the rolling is finished, the steel sheet enters the laminar flow cooling device and is cooled to 620°C at a rate of 12°C / s, and finally the steel sheet can be obtained. The 500 times metallographic structure of the steel strip is shown as figure 1 Shown.

Embodiment 3

[0046] The embodiment is the same as in Example 1, where the heating temperature is 1226°C, and the total furnace time is 260 minutes; the opening temperature of the first stage rolling is 1180°C, and the thickness of the intermediate billet is 80mm; the opening temperature of the second stage rolling is The final rolling temperature is 930°C, the final rolling temperature is 850°C, and the thickness of the finished steel sheet is 40mm. After rolling, the steel sheet enters the laminar flow cooling device and is cooled to 610°C at a rate of 15°C / s. Finally, the steel sheet can be obtained.

[0047] Table 1 Chemical composition of Examples 1 to 3 of the present invention (wt%)

[0048] Example

C

Si

Mn

P

S

Cu

Ni

Cr

Als

Ce

1

0.08

0.23

0.63

0.014

0.004

0.31

0.21

0.48

0.025

0.0008

2

0.08

0.21

0.61

0.014

0.004

0.33

0.22

0.47

0.024

0.0042

3

0.09

0.25

0.73

0.011

0.002

0.34

0.18

0.43

0.028

0.0024

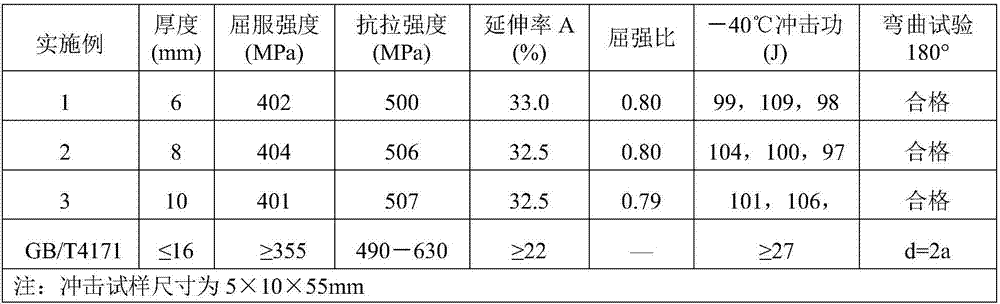

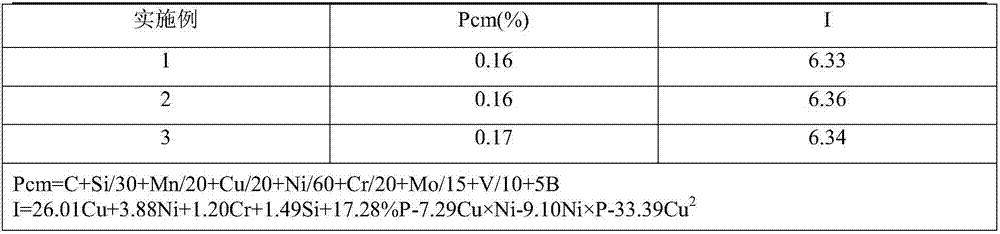

[0049] The steel strips of Examples 1 to 3 of the present invention were tested for mechanical properties, and the test...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com