Wear-resistant modified HNBR (hydrogenated nitrile butadiene rubber), NBR (nitrile butadiene rubber) and NBR/PVC (polyvinyl chloride) dynamic sealing material adopting molybdenum disulfide solid lubricant and preparation method for same

A technology of solid lubricants and molybdenum disulfide, applied in chemical instruments and methods, and other chemical processes, can solve problems such as poor ozone resistance, poor electrical properties, and poor low temperature resistance, and achieve enhanced modification effects and excellent friction reduction Good anti-wear performance and aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

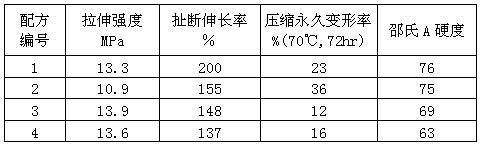

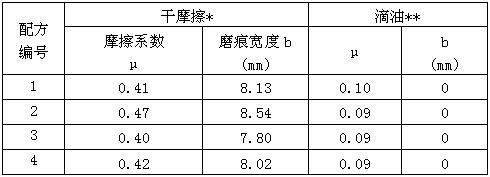

Examples

Embodiment 1

[0024] In Example 1, 100 parts by mass of nitrile rubber (brand: NBR-26) and 8 parts by mass of molybdenum disulfide MoS are used in this embodiment. 2 , 2 parts by mass of zinc oxide, 60 parts by mass of carbon black, 0.3 parts by mass of stearic acid, 4 parts by mass of 2,5-dimethyl-2,5 (di-tert-butylperoxy) hexane (DBPH), 2 parts by mass Parts of 2-mercaptobenzimidazole (MBI), 1 part by mass of N-phenyl-2-naphthylamine (D), 6 parts by mass of triallyl isocyanurate (TAIC), 10 parts by mass of phthalic acid Dioctyl formate (DOP). Using low-temperature mixing, first add 100 parts by mass of the base rubber compound, then add molybdenum disulfide, zinc oxide, carbon black, stearic acid, antioxidant, accelerator, vulcanizing agent, plasticizer, and mixing roll temperature 40~60℃, the prepared rubber compound should be parked for 16~20 hours; before vulcanization, the above-mentioned rubber compound is re-mixed and thinned out, and the rubber compound is vulcanized and molded. The...

Embodiment 2

[0025] In the second embodiment, 100 parts by mass of nitrile rubber polyvinyl chloride blend (brand: NBR-26 / PVC-32) and 10 parts by mass of molybdenum disulfide MoS are used in this embodiment. 2 , 2 parts by mass zinc oxide, 80 parts by mass carbon black, 0.2 parts by mass stearic acid, 6 parts by mass 2,5-dimethyl-2,5 (di-tert-butylperoxy) hexane (DBPH), 1 mass Parts of 2-mercaptobenzimidazole (MBI), 1 part by mass of N-phenyl-2-naphthylamine (D), 4 parts by mass of triallyl isocyanurate (TAIC), 5 parts by mass of phthalic acid Dioctyl formate (DOP). Others are the same as the first embodiment.

Embodiment 3

[0026] Example 3: This embodiment uses 100 parts by mass of hydrogenated nitrile butadiene rubber (brand: Zetpol2010L) and 5 parts by mass of molybdenum disulfide MoS 2 , 3 parts by mass zinc oxide, 50 parts by mass carbon black, 0.5 parts by mass stearic acid, 5 parts by mass 2,5-dimethyl-2,5 (di-tert-butylperoxy) hexane (DBPH), 1 mass Parts of 2-mercaptobenzimidazole (MBI), 1 part by mass of N-phenyl-2-naphthylamine (D), 5 parts by mass of triallyl isocyanurate (TAIC), 5 parts by mass of phthalic acid Dioctyl formate (DOP). Others are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com