Preparation method of nano calcium carbonate used for weather proofing silicone sealant

A nano-calcium carbonate and sealant technology, applied in the directions of adhesive additives, dyed low-molecular-weight organic compounds, dyed high-molecular organic compounds, etc., can solve the problems of high modulus, poor processing performance, poor fluidity, etc. Low modulus, simple and feasible process, and the effect of reducing modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

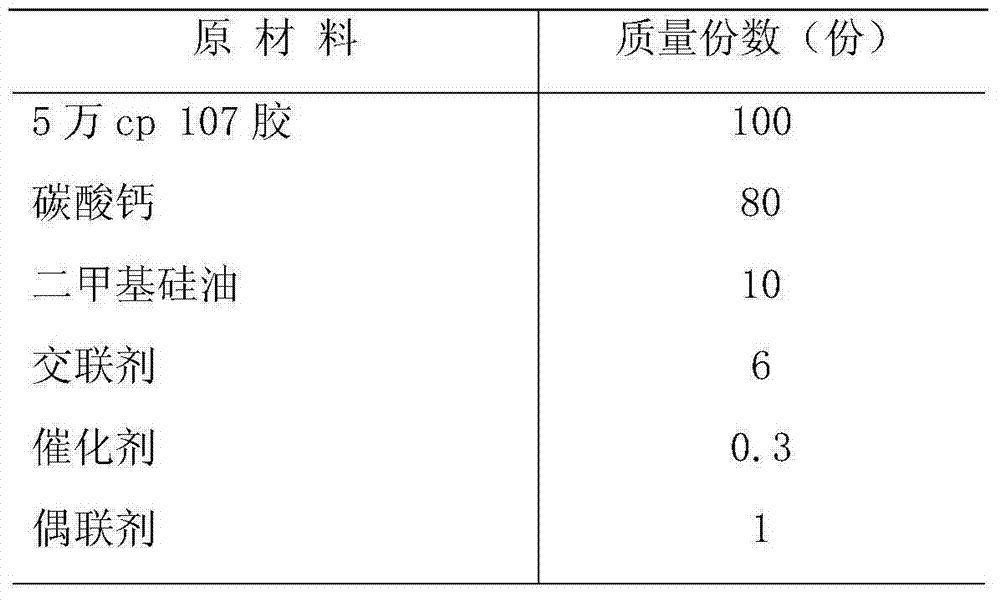

Method used

Image

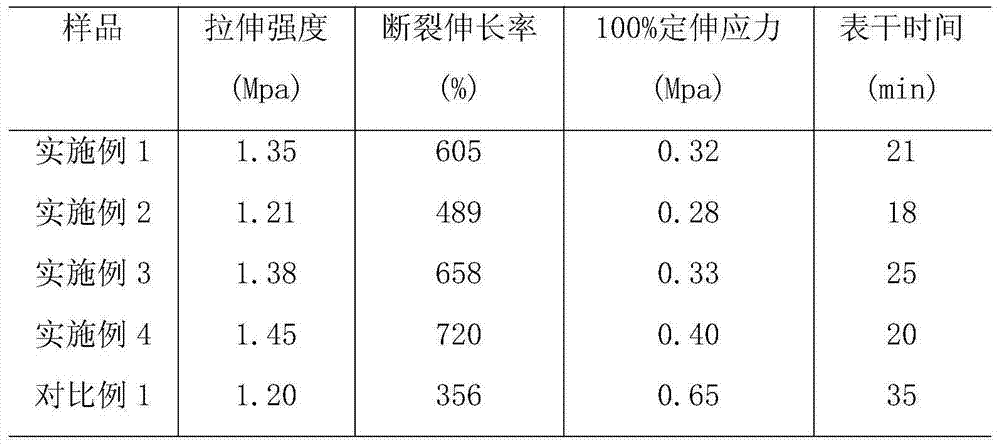

Examples

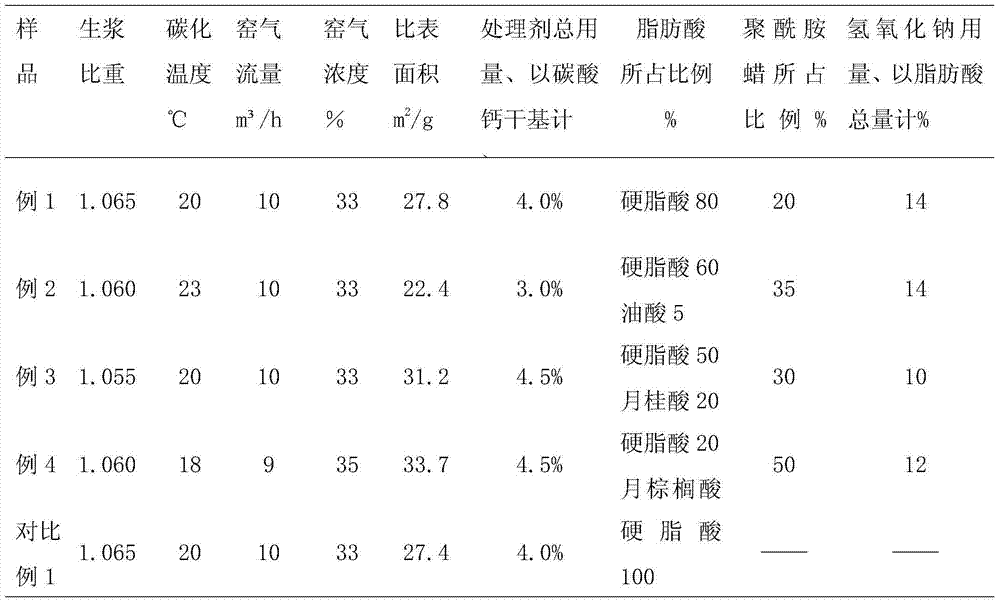

Embodiment 1

[0033] Dilute the milk of lime that has been refined and aged for 48 hours, adjust the specific gravity to 1.065, control the temperature at 20°C, and then transport it to the carbonation reaction kettle; enter the purified and cooled lime kiln gas for carbonation reaction, kiln gas The flow rate is 10m 3 / h, the volume content of carbon dioxide is 33%, when the pH of the reaction solution drops to 7.0, the carbonation reaction is completed, and the specific surface area of cooked pulp is 27.8m 2 / g;

[0034] Prepare the composite surface treatment agent of 4.0% (in calcium carbonate dry basis): wherein fatty acid is selected stearic acid for use, and its consumption is 80% of surface treatment agent total amount, and polyamide wax consumption is 20% of surface treatment agent total amount , hot water temperature is 95 ℃, and sodium hydroxide consumption is 14% of stearic acid total amount;

[0035] Transfer the carbonized slurry to the surface treatment tank, raise the te...

Embodiment 2

[0038] Dilute the milk of lime that has been refined and aged for 48 hours, adjust the specific gravity to 1.060, control the temperature at 23°C, and then transport it to the carbonation reaction kettle; pass it into the purified and cooled lime kiln gas for carbonation reaction, kiln gas The flow rate is 10m 3 / h, the volume content of carbon dioxide is 33%, when the pH of the reaction solution drops to 7.0, the carbonation reaction is completed, and the specific surface area of cooked pulp is 22.4m 2 / g;

[0039] Prepare the compound surface treatment agent of 3.0% (calcium carbonate dry basis): wherein stearic acid consumption is 60% of surface treatment agent total amount, oleic acid consumption is 5% of surface treatment agent total amount, polyamide wax consumption It is 35% of the total amount of surface treatment agent, the temperature of hot water is 95°C, and the amount of sodium hydroxide is 14% of the total amount of fatty acids;

[0040] Transfer the carboniz...

Embodiment 3

[0043] Dilute the milk of lime that has been refined and aged for 48 hours, adjust the specific gravity to 1.055, control the temperature at 20°C, and then transport it to the carbonation reaction kettle; enter the purified and cooled lime kiln gas for carbonation reaction, kiln gas The flow rate is 10m 3 / h, the volume content of carbon dioxide is 33%, when the pH of the reaction solution drops to 7.0, the carbonation reaction is completed, and the specific surface area of cooked pulp is 31.2m 2 / g;

[0044] Prepare the composite surface treatment agent of 4.5% (calcium carbonate dry basis): wherein stearic acid consumption is 50% of surface treatment agent total amount, lauric acid consumption is 20% of surface treatment agent total amount, polyamide wax consumption It is 30% of the total amount of surface treatment agent, the temperature of hot water is 95°C, and the amount of sodium hydroxide is 10% of the total amount of fatty acids;

[0045] Transfer the carbonized sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com