Anti-crack and anti-leak construction method of arranging tower crane foundation below waterproof baseplate

A technology of tower crane foundation and construction method, which is applied in basic structure engineering, protection devices, buildings, etc., can solve problems such as affecting the waterproof effect of waterproof bottom plate, negative bending moment, and settlement difference between tower crane foundation and waterproof bottom plate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

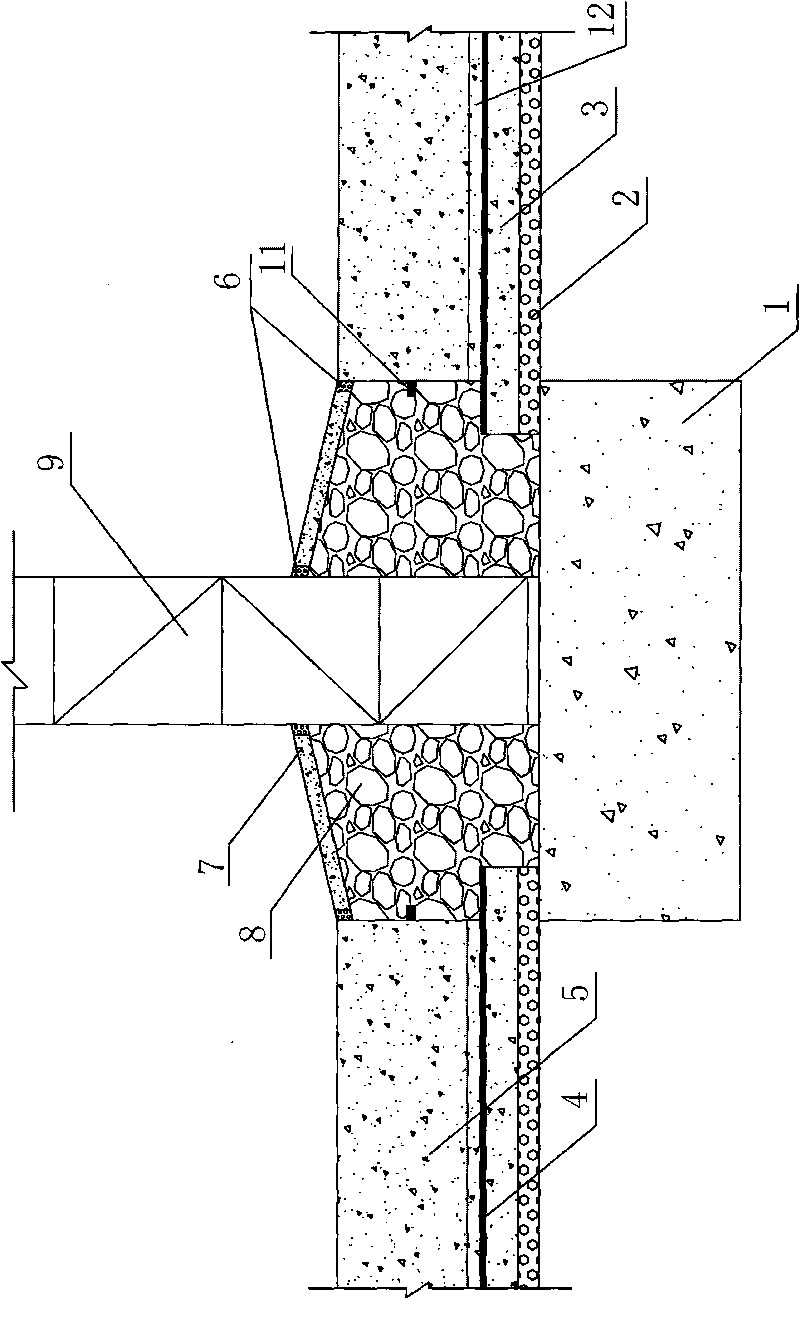

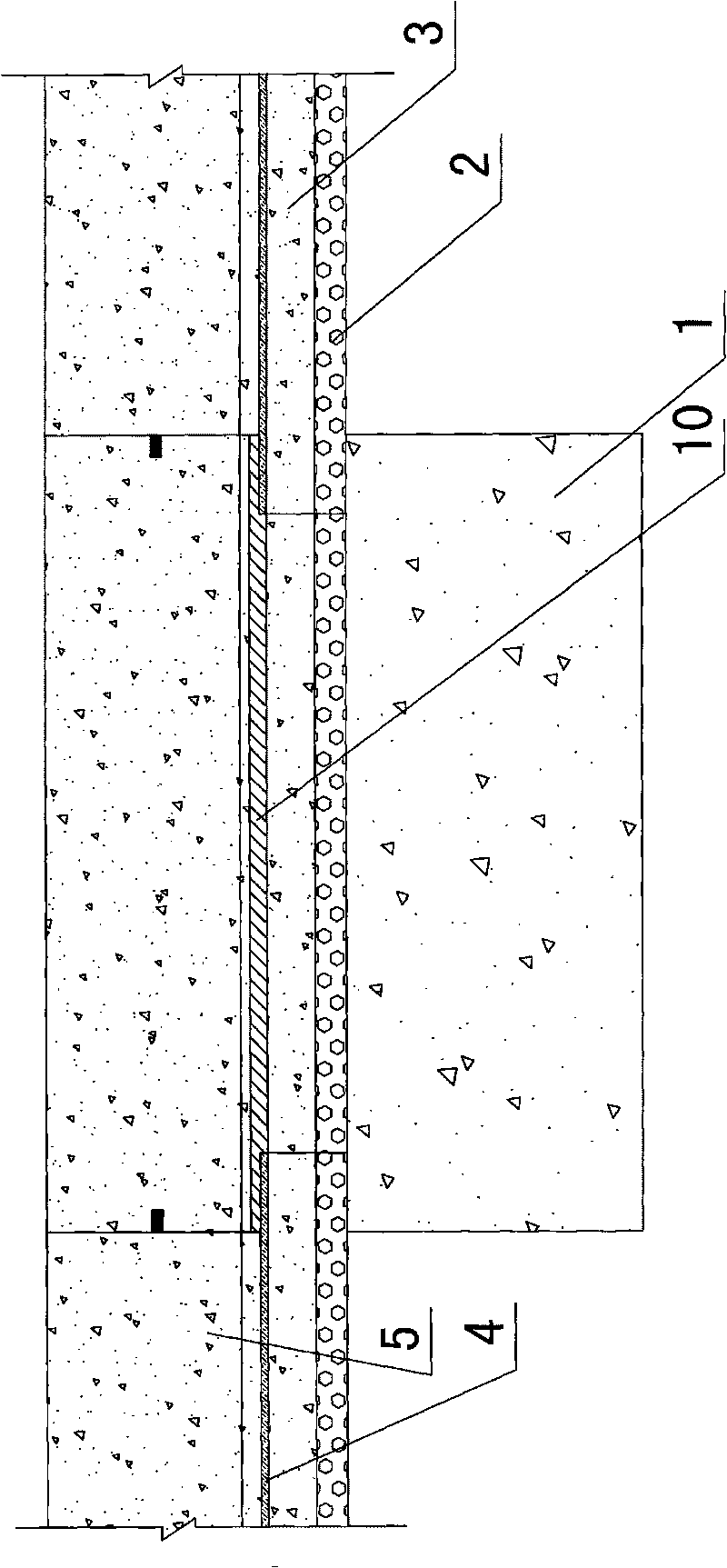

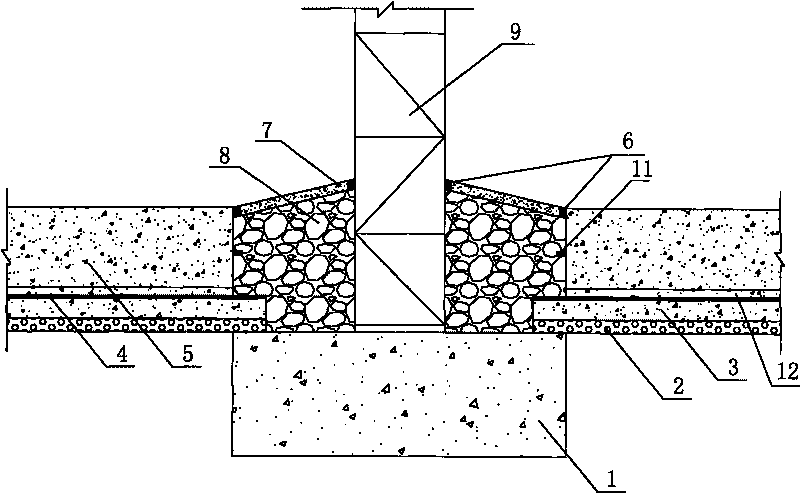

[0016] Such as Figure 1-2 The described embodiment adopts the following steps:

[0017] 1) Tower crane foundation 1 construction;

[0018] 2) Install the tower crane 9, and then carry out the construction of the flexible cushion 2, the concrete cushion 3, the waterproof layer 4, the waterproof protection layer 12, and the waterproof bottom plate 5 around the tower crane foundation 1 from bottom to top, wherein the flexible cushion 2, the concrete cushion 3. The waterproof layer 4 penetrates into the tower crane foundation 1 at a distance of 200mm, and the bottom surface of the flexible cushion layer 2 is flush with the top surface of the tower crane foundation 1;

[0019] 3) The range of the tower crane foundation 1 is rammed with plain soil 8, rammed with plain soil 8 to 100mm below the top surface of the waterproof bottom plate 5, and then sealed with C20 anti-seepage concrete from the center of the tower crane 9 to the surroundings and calendered to prevent seepage, do 2%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com