Vacuum internal-combustion type grey-brick-tile baking method using shale as raw material

A raw material and vacuum technology, applied in the field of building ceramic tile firing, can solve problems such as threats to land resources, and achieve the effect of uniform, firm and stable color quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

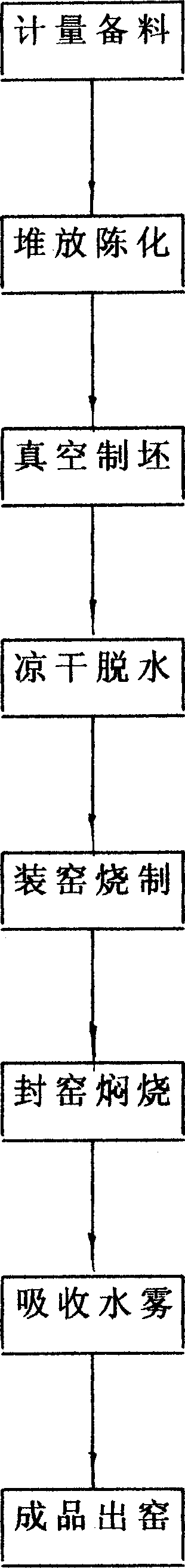

[0022] The method proposed by the present invention is to use shale as a raw material vacuum internal combustion type to burn green bricks and tiles, and it is carried out by the following steps successively:

[0023] (1) Measuring and preparing materials: The shale is blasted by blasting in the mountains, and the materials are manually selected and transported back to the workshop for standby, and the commercially purchased coal materials are used, and the raw materials are weighed according to the following weight:

[0024] 1 part shale,

[0025] Coal 0.25 parts,

[0026] Send the weighed raw materials into a pulverizer to pulverize to form a mixed material with a block size of 6mm, and then send the mixed material to a ray mill for ball milling to form a mixed powder with a particle size of 260 mesh.

[0027] (2) Stacking and aging: the prepared mixed powder is stacked indoors for natural aging treatment for 3 days, and the moisture inside the mixed powder can be completel...

Embodiment 2

[0035] The method proposed by the present invention is to use shale as the raw material vacuum internal combustion type to burn the green brick and tile method, is to carry out by following steps successively:

[0036] (1) Measuring and preparing materials: The shale is blasted by blasting in the mountains, and the materials are manually selected and transported back to the workshop for standby, and the raw materials are weighed according to the weight ratio as follows:

[0037] 1 part shale,

[0038] Coal 0.35 parts,

[0039] Send the weighed raw materials into a pulverizer to pulverize to form a mixed material with a block size of 10 mm, and then send the mixed material to a ray mill for ball milling to form a mixed powder with a particle size of 320 mesh.

[0040] (2) Stacking and aging: the mixed powder was stacked and aged indoors for 2 days.

[0041] (3) Vacuum billet making: Weigh the mixed powder that has been stacked and aged and put it into the mixer, and add 5% sa...

Embodiment 3

[0048] The method proposed by the present invention is to use shale as the raw material vacuum internal combustion type to burn the green brick and tile method, is to carry out by following steps successively:

[0049] (1) Measuring and preparing materials: Weigh raw materials according to the following weight:

[0050] 1 part shale,

[0051] Coal 0.1 part,

[0052] Send the raw materials into a pulverizer to pulverize to form a mixed material with a block size of 4 mm, and then send the mixed material to a ray mill for ball milling to form a mixed powder with a particle size of 220 mesh.

[0053] (2) Stack aging: stack the mixed powder indoors for natural aging for 1 day.

[0054] (3) Vacuum billet making: Put the mixed powder that has been stacked and aged into a mixer, add water according to 12% of the weight of the mixed powder, and then fully stir to make a uniformly stirred billet mud, and send it into the vacuum The blank can be made by extruding in the extrusion mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com