Laminating equipment for sound-proof laminating cotton

A film covering and equipment technology, applied in the field of sound-absorbing materials, can solve the problems of polluting the environment, sound-proof cotton wadding and lint flying, and achieve the effects of reducing noise, preventing wadding and lint flying, and saving labor and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

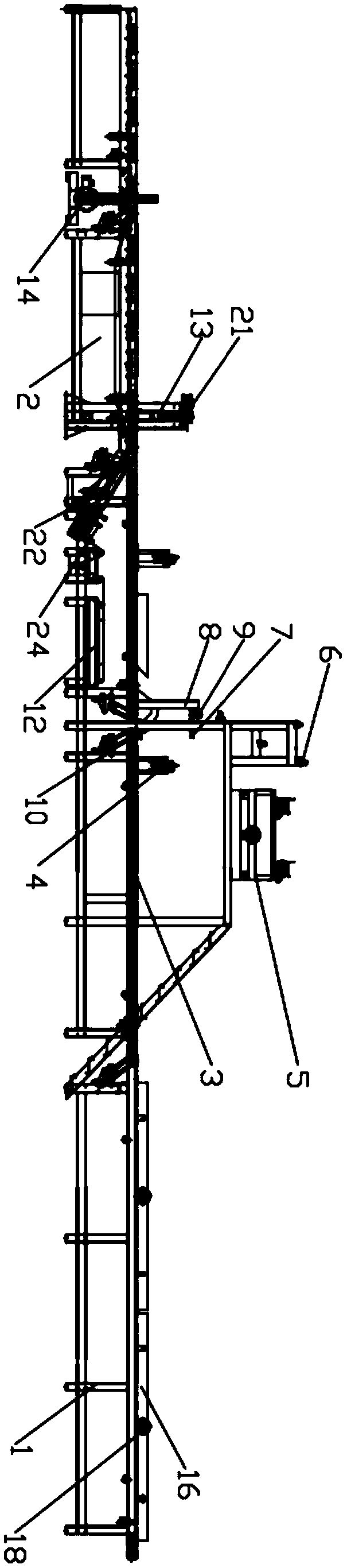

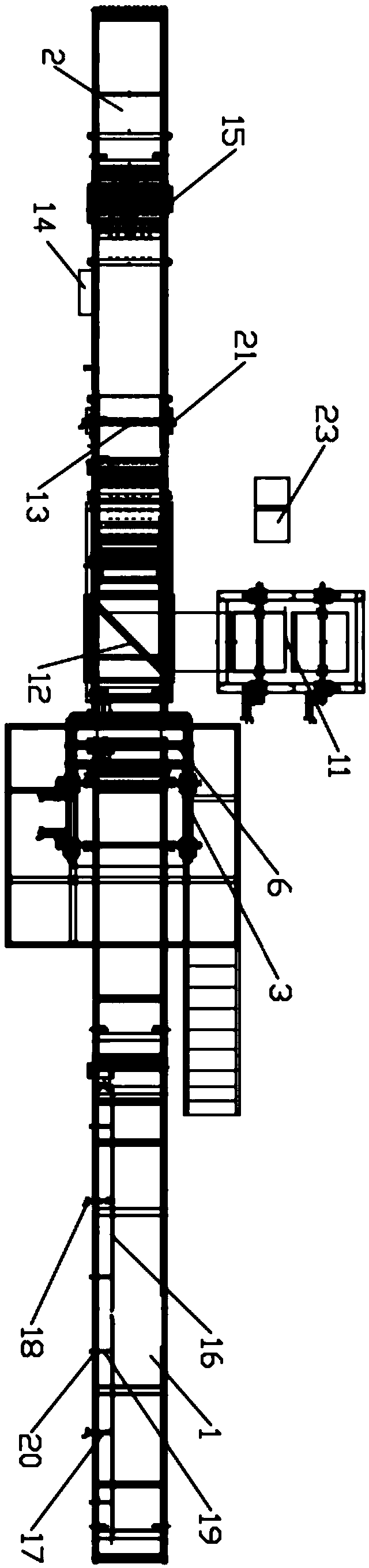

[0025] Such as Figure 1-6 As shown, a film-coating equipment for sound-proof film-coated cotton includes an input platform 1, a film-coating device and an output platform 2.

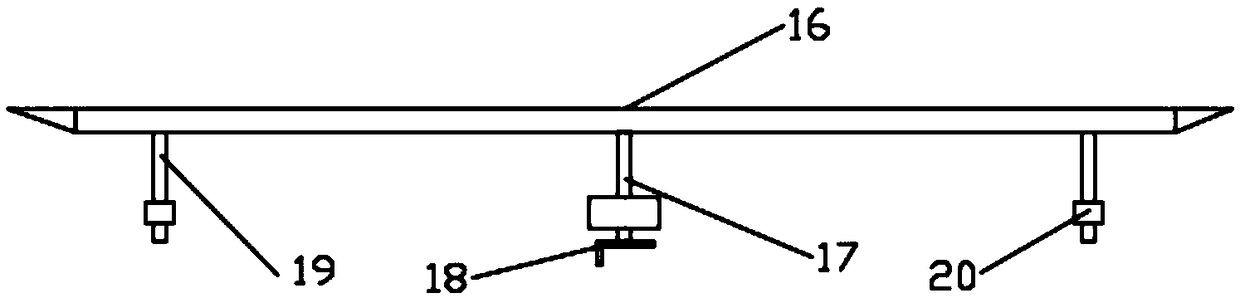

[0026] One side above the input platform 1 is provided with a position adjustment plate 16, and the position adjustment plate 16 is connected to the input platform 1 through a position adjustment device. Described adjusting device comprises threaded rod 17, and described threaded rod 17 is screwed on the described input platform 1, and one end of described threaded rod 17 is welded on described position adjusting plate 16, and the other end of described threaded rod 17 Connect with shaking handle 18. The positioning device also includes an auxiliary positioning rod 19 and a collar 20, the collar 20 is fixed on the input platform 1, one end of the auxiliary positioning rod 19 is welded on the input platform 1, and the other One end passes through the collar 20 . Turning the rocking handle 18 makes the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com