Wood grinding and polishing device for assisting wood spraying

A polishing device, wood technology, applied in the direction of grinding/polishing safety device, grinding/polishing equipment, grinding machine, etc., can solve the problems of easily causing respiratory diseases, environmental pollution, mass and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

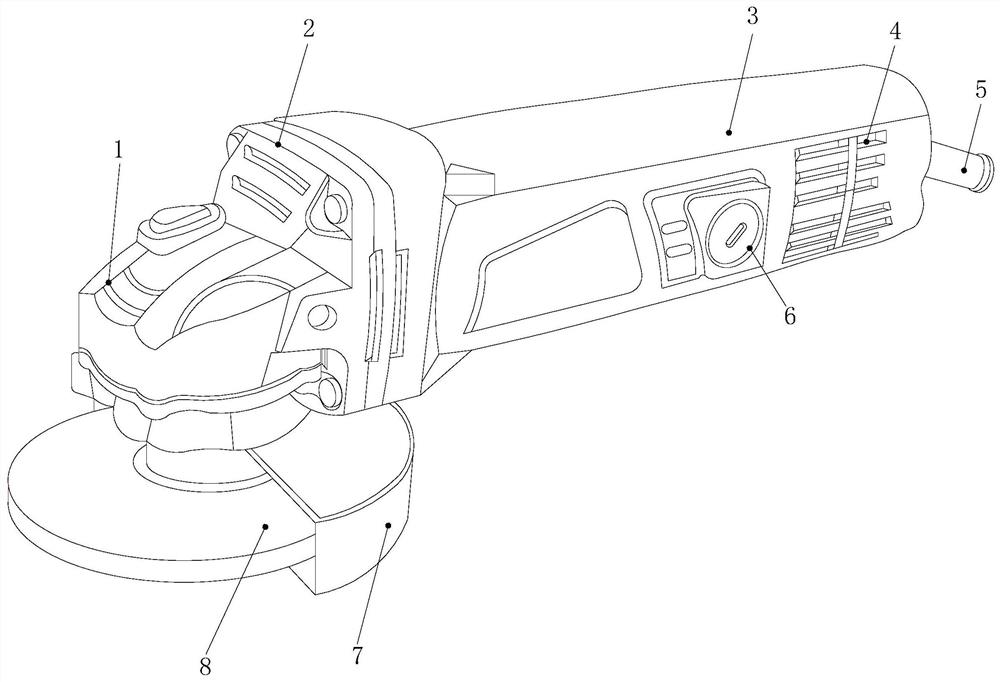

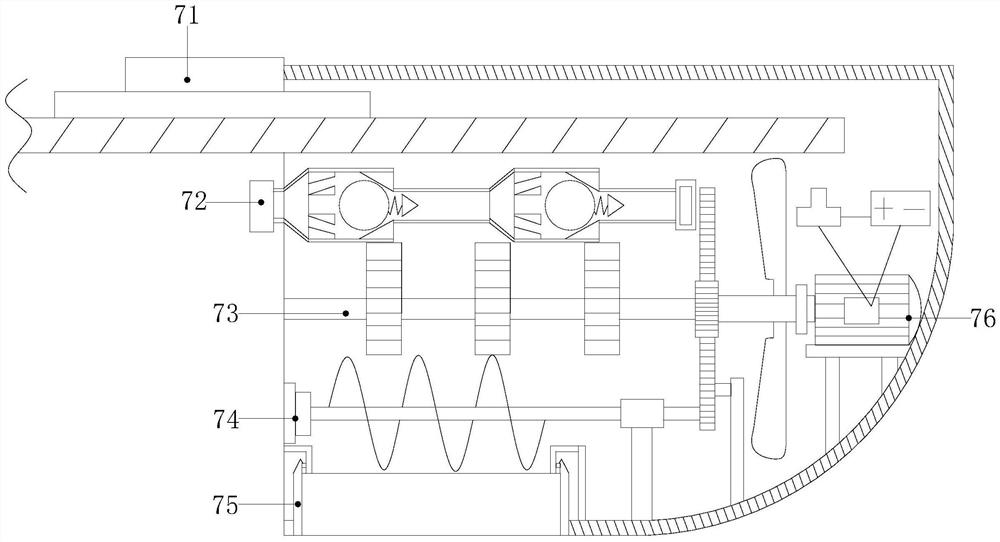

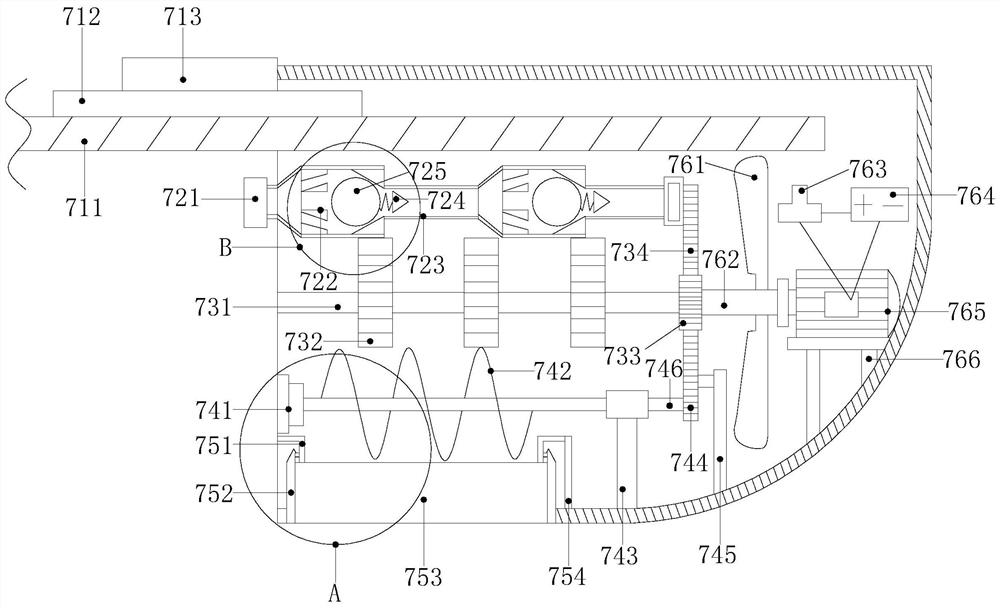

[0024] Such as Figure 1-Figure 5As shown, the present invention provides a wood grinding and polishing device for assisting wood spraying, and its structure includes: a grinding machine head 1, a connection plate 2, a handle 3, a cooling hole 4, an external connecting wire 5, a governor 6, and a protective cover 7. Grinding sheet 8, the grinding machine head 1 is located on the left side of the connection plate 2 and is fixedly connected with the connection plate 2 by screws, the connection plate 2 is buckled and fixed on the left side of the handle 3, the heat dissipation hole 4 is connected with the handle 3 is an integrated mechanism component, the external connecting wire 5 passes through the right side of the handle 3 and is electrically connected to the internal electrical system of the handle 3, and the grinding sheet 8 is horizontally fixed on the bottom of the grinding head 1 and connected to the grinding head 1 Transmission connection, the protective cover 7 is weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com