Coal granule flying inhibitor mixture, and preparation method and application method thereof

A technology of inhibitors and mixtures, applied in the field of chemistry, can solve the problems of pollution, increase the danger of operators, and cannot completely prevent dust, etc., and achieve the effects of comfort and health, easy operation, and prevention of scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

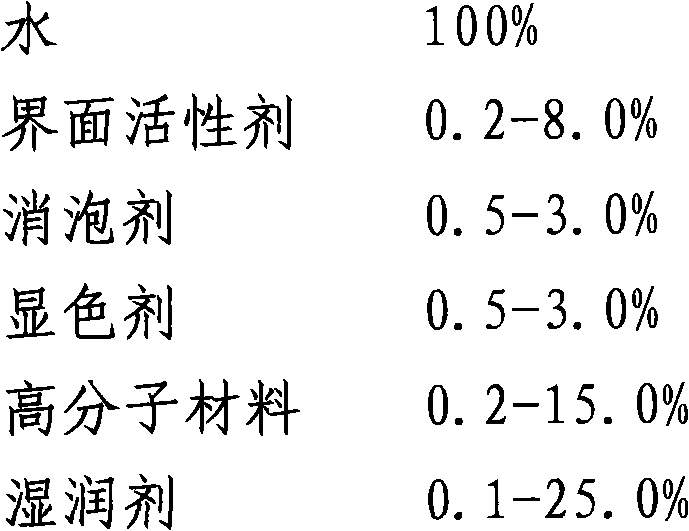

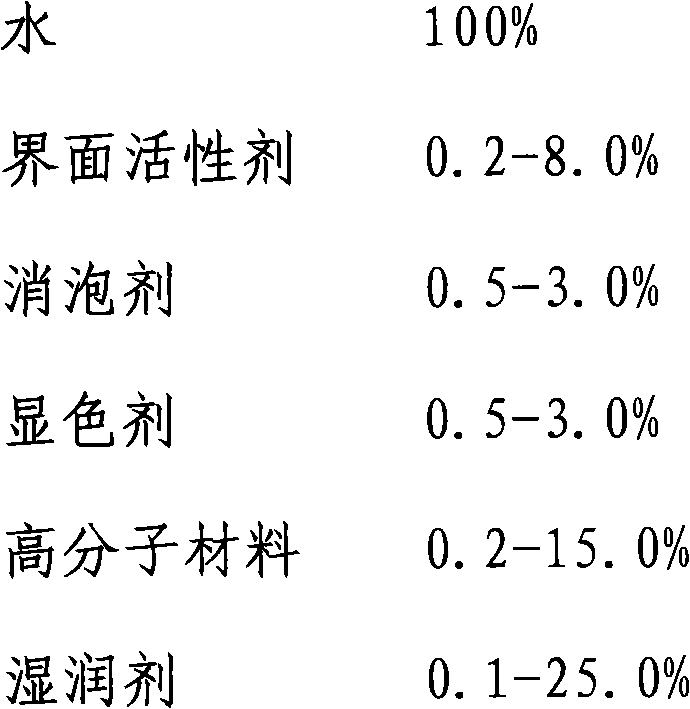

Method used

Image

Examples

Embodiment 1

[0028] At normal temperature, in the mixing equipment, add 0.7 liters of water, then add polyvinyl alcohol 100.0g, sorbitan monooleate 10.0g and ethanol 20.0g, titanium dioxide (TiO2) 20.0g, stir for 30 minutes. Then raise the temperature to 30°C, at this temperature, slowly add 50.0g of sodium alginate dropwise, stir at 600 rpm, stir at high speed for 3 hours, and cool at room temperature to obtain a viscous white coal scatter inhibitor agent mixture.

Embodiment 2

[0030] At room temperature, add 0.7 liters of water to the mixing equipment, then add 30.0 g of dodecyl dimethyl amine oxide, 15.0 g of organosiloxane, magnesium hydroxide (MgOH) 2 15.0 g, stirred for 60 minutes. Then raise the temperature to 40°C. At this temperature, slowly drop 70.0 g of carboxymethyl cellulose, stir at 400 rpm, stir at high speed for 2.5 hours, and cool at room temperature to obtain viscous white coal. Scatter inhibitor mixture.

Embodiment 3

[0032] At room temperature, add 0.7 liter of water to the mixing equipment, then add 20.0 g of sorbitan monolauryl RATE, 10.0 g of polyether, and 8.0 g of talc (Talc), and stir for 40 minutes. Then raise the temperature to 35°C, at this temperature, slowly drop 60.0g of hydroxypropyl methylcellulose, stir at 500 rpm, stir at high speed for 2 hours, cool at room temperature, and obtain viscous White Coal Scatter Inhibitor Mixture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com