Carving device for wooden door production

A technology for wooden doors and support plates, applied in wood processing appliances, forming/shaping machines, manufacturing tools, etc., can solve the problems of no positioning mechanism, pattern offset, time-consuming and labor-intensive, etc., to prevent dust flying, improve carving quality, Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

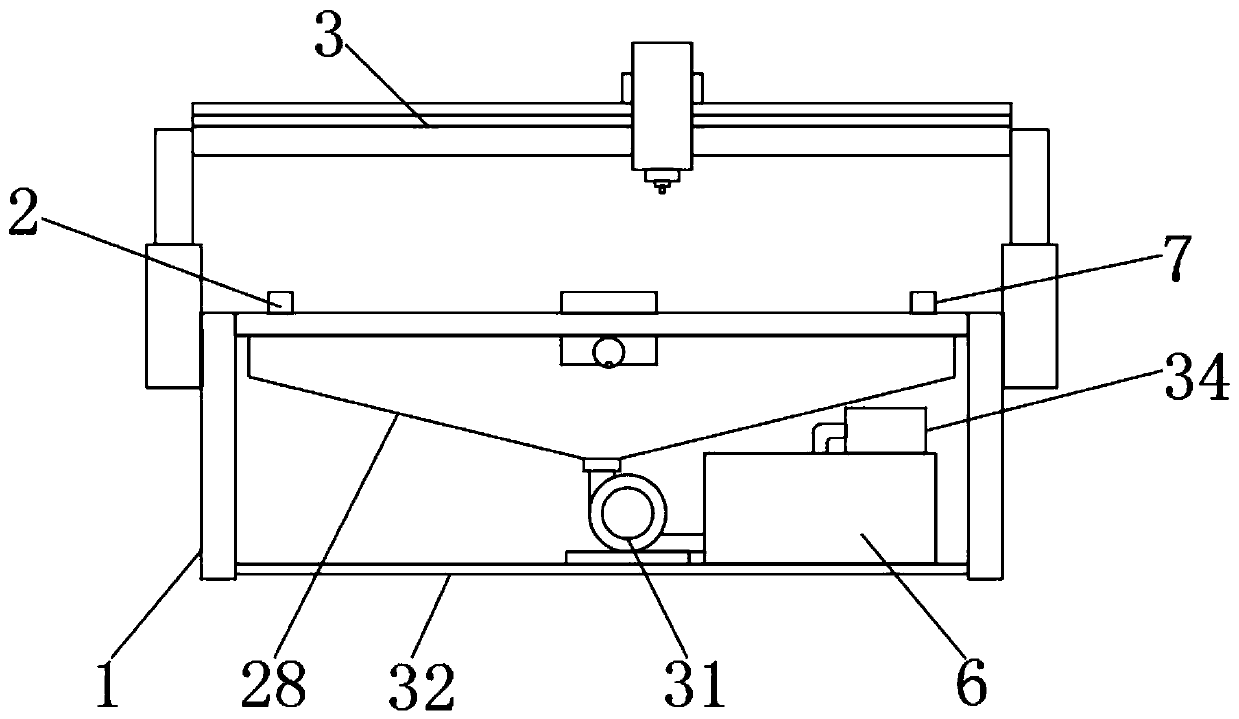

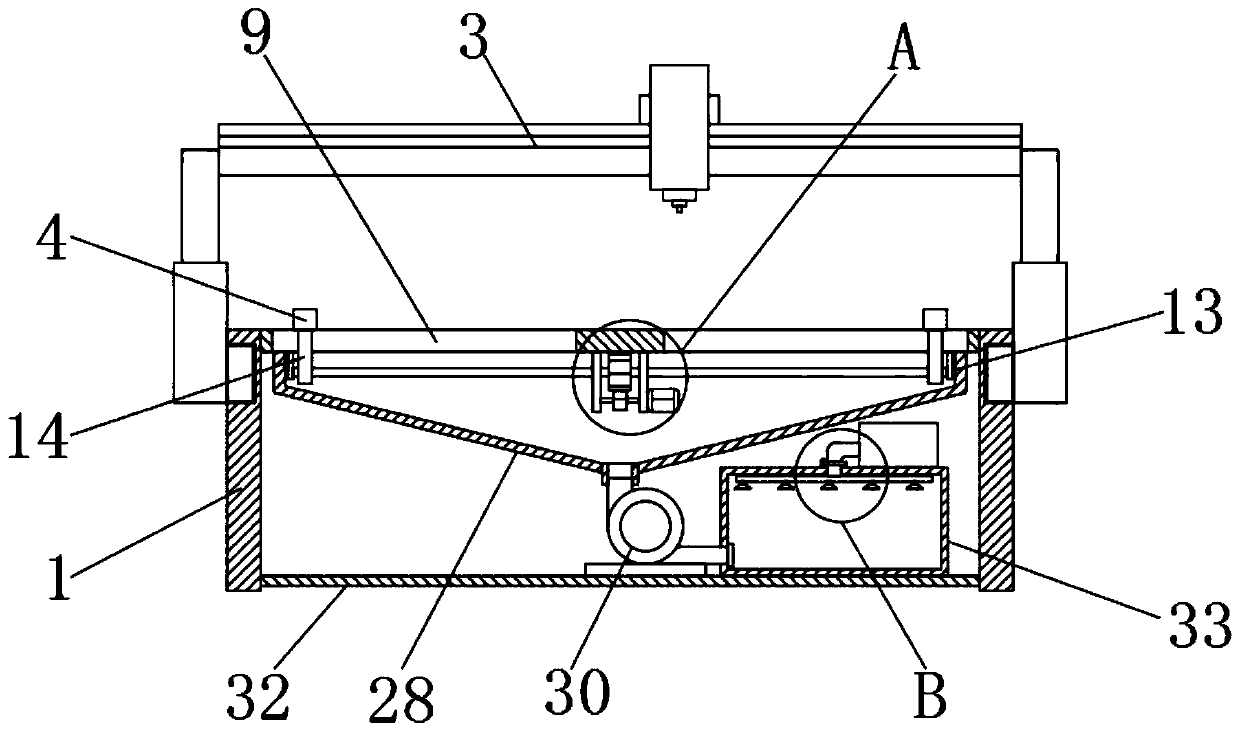

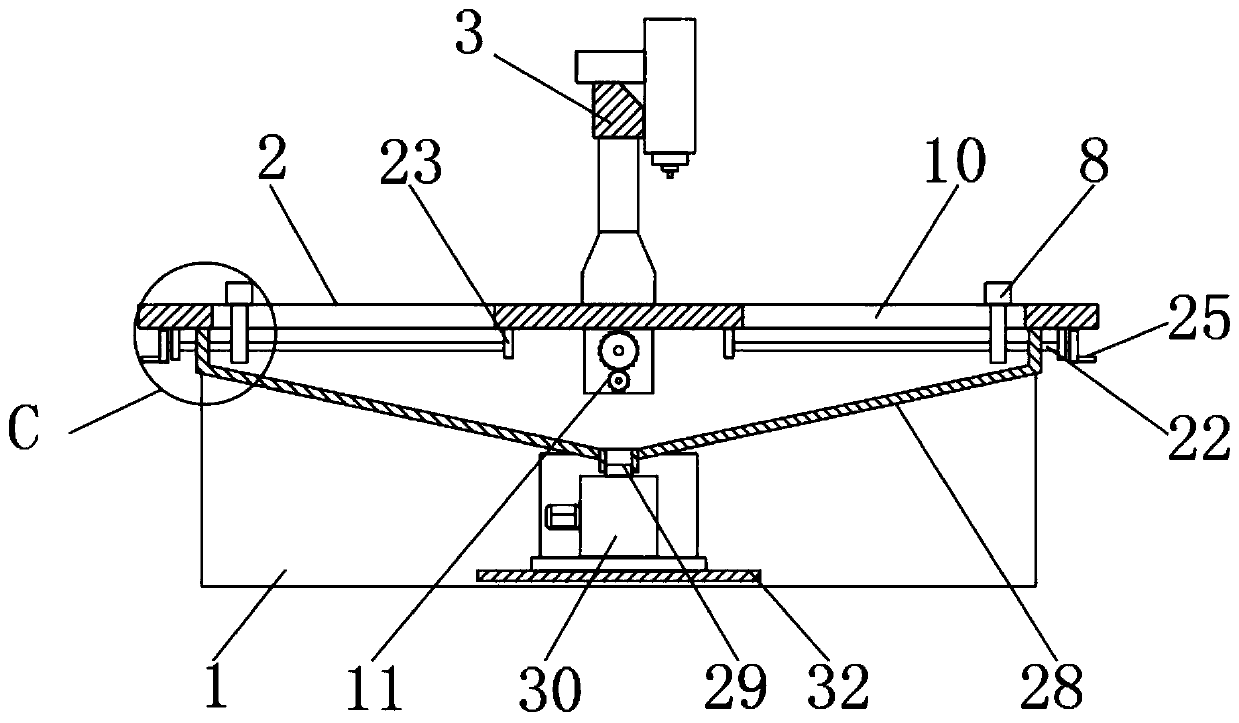

[0030] Specific embodiments: when the wooden door needs to be carved, first the wooden door is placed on the support plate 2, at this moment, the driving motor 16 runs, so that the driving rod 18 drives the driving gear 20 to rotate, and because the driving gear 20 and the driven gear 21 meshing connection, so that the driven gear 21 drives the screw rod 12 to rotate relatively on the two fixed plates 13, and the screw rod 12 used in this program is composed of two threads in opposite directions. At this time, the rotating sleeve The two moving sleeves 14 connected to the outside of the screw mandrel 12 are subjected to driving forces in two opposite directions, and because the moving sleeves 14 are sleeved on the chute 9 and under the position-limiting action of the first positioning plate 15 slidably connected to the support plate 2, Furthermore, the two moving sleeves 14 drive the two first positioning plates 15 to move towards each other, so as to achieve the effect of clam...

specific Embodiment approach

[0032] The specific embodiment: when the both sides of the wooden door are clamped, at this time, the two handles 25 relative to the other two sides of the wooden door are rotated simultaneously, and the driving force received by the handle 25 makes the threaded rod 22 relative to the first limiting plate 23 and the first limiting plate 23 respectively. The second limiting plate 24 rotates, and now the limiting sleeve 26 is driven by the threaded rod 22, and the limiting action of the limiting sleeve 26 on the limiting groove 10 and the second positioning plate 27 slidably connected on the support plate 2 Under force, the two position-limiting sleeves 26 are relatively moved on the two threaded rods 22, so as to realize the relative movement of the two second positioning plates 27 along the two position-limiting grooves 10 on the support plate 2 , so as to realize the clamping and fixing effect of the two positioning plates on the other two sides of the wooden door.

[0033] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com