Integrated power supply equipment

A technology for power supply equipment and cabinets, applied in the field of integrated power supply equipment, can solve the problems of reduced heat dissipation of the power supply cabinet and inability to fully exert the operation performance of the power supply cabinet, and achieve the effect of reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

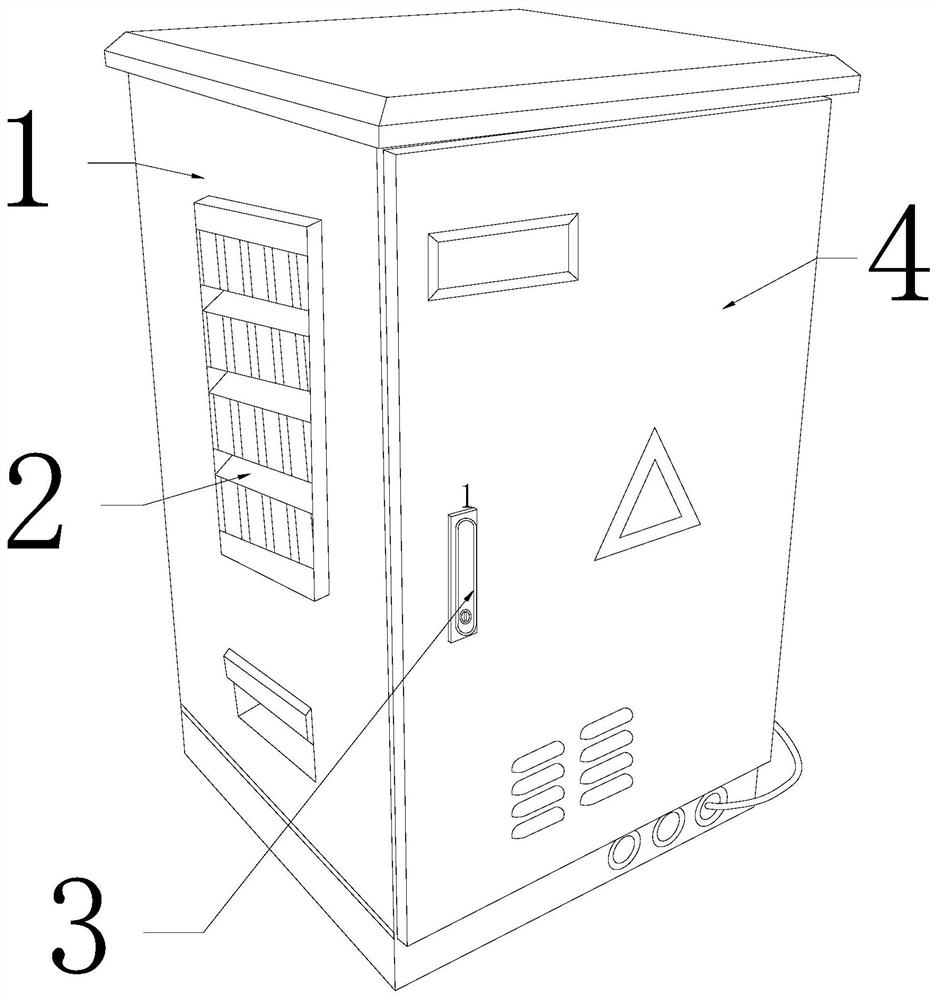

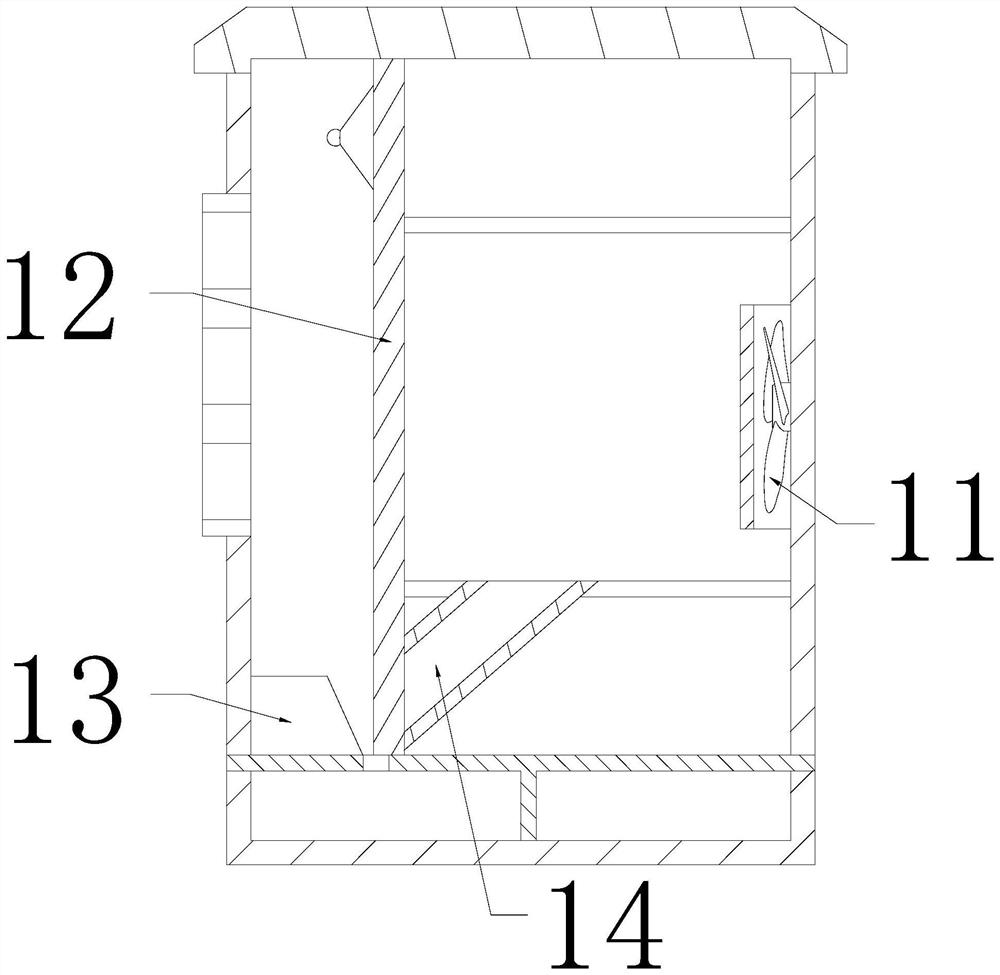

[0029] as attached figure 1 to attach Figure 6 Shown:

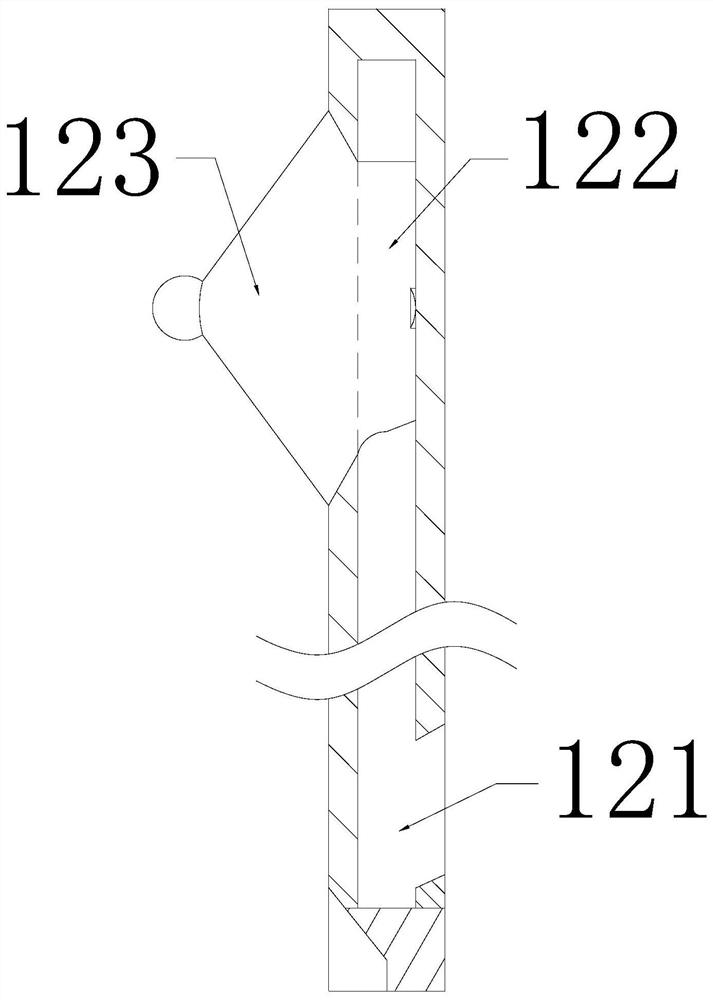

[0030] The invention provides an integrated power supply device, the structure of which includes a box body 1, a ventilation plate 2, a handle 3, and a box door 4. The ventilation plate 2 is installed on the left side of the box body 1, and the handle 3 is embedded in the box The front end of the door 4, the right side of the box door 4 is hingedly connected with the box body 1, and the box body 1 is provided with a cooling fan 11, a heat conducting plate 12, a limiting plate 13, and an air duct 14, and the cooling fan 11 Installed inside the box body 1, the upper and lower ends of the heat conduction plate 12 are respectively embedded and connected with the inside of the box body 1, the limit plate 13 is installed in the lower left corner of the box body 1, and the air guide tube 14 is embedded with the heat conduction plate 12. The air guide pipe 14 can guide the wind blown by the heat dissipation fan 11 into the hea...

Embodiment 2

[0038] as attached Figure 7 to attach Figure 8 Shown:

[0039] The present invention provides an integrated power supply device. The limit plate 13 is provided with a push-pull bar 131, a receiving block 132, and a chip removal block 133. The push-pull bar 131 is embedded in the upper right corner of the limit plate 13. The receiving block The left end of 132 slides between the limiting plate 13 and the chip removal block 133, and the right end is embedded and connected with the push-pull bar 131. The chip removal block 133 cooperates with the internal clearance of the limit plate 13, and the push-pull bar 131 is along the limit plate. 13 is installed at a slope angle on the right side, and has good resilience. The chip removal block 133 is installed at 45 degrees to the horizontal direction of the limit block 13, which is conducive to scraping the top of the scraper block 123. When the scraper block 123 falls to At the bottom of the heat conducting plate 12, the push-pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com