Odor removing device of textile equipment

A technology for textile equipment and deodorization, which is applied in the direction of removing smoke and dust, using liquid separating agent, cleaning methods and utensils, etc. It can solve problems such as equipment failure, damage, pungent nose, etc., and achieve high versatility and prevent clogging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

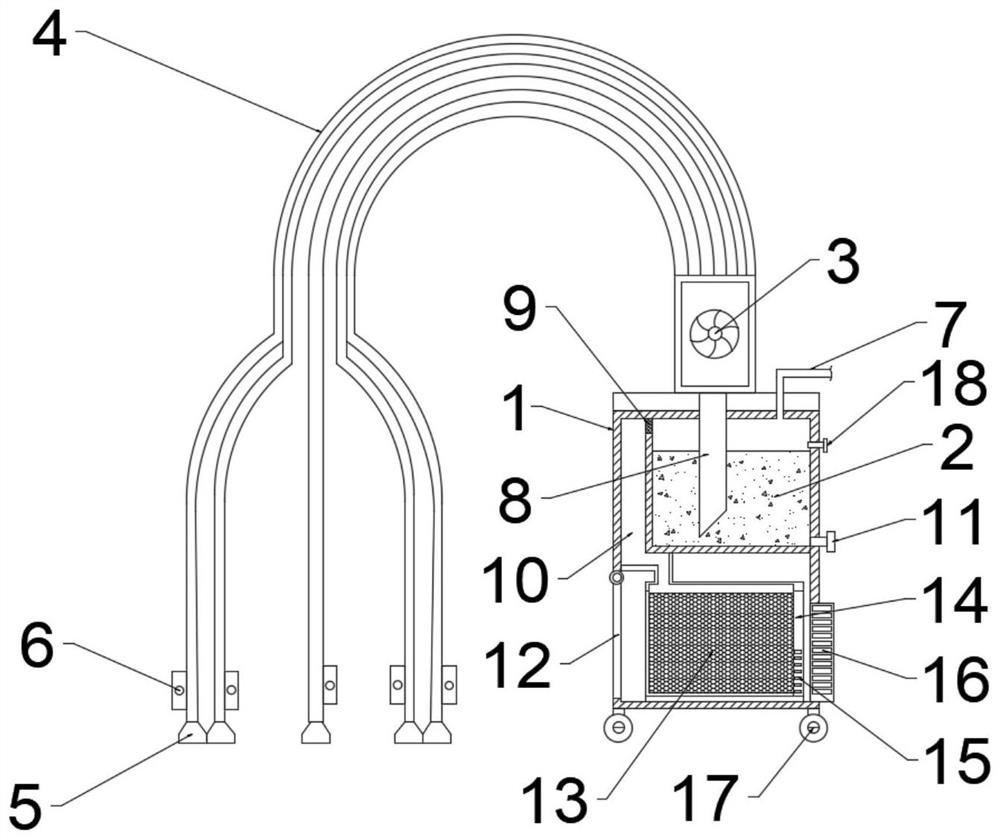

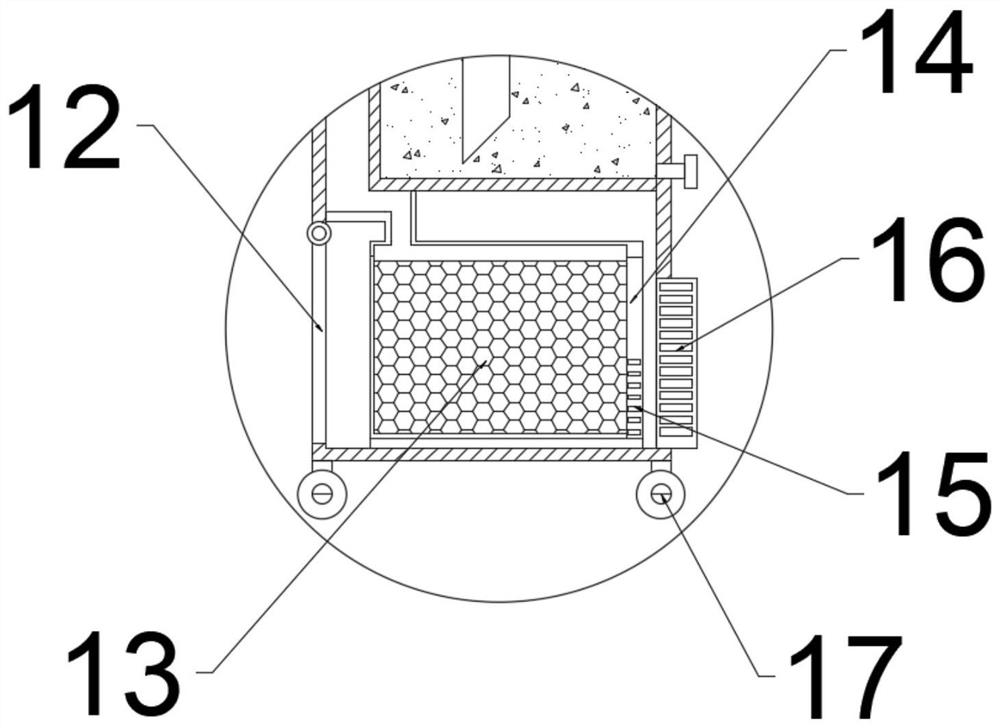

[0023] see Figure 1 ~ Figure 2 , a kind of deodorization device for textile equipment, including deodorization box 1, dedusting pool 2, elbow 4 and drawer box 14, wherein the dedusting pool 2 for absorbing cotton dust is installed on the top of deodorization box 1 for absorbing gas The elbow 4 is installed on the outside of the deodorization box 1, and the drawer 14 for holding the activated carbon 13 is installed on the bottom of the deodorization box 1.

[0024] The top of the deodorization box 1 is provided with an air pump 3, the upper end of the air pump 3 is connected with the elbow 4, the lower end of the air pump 3 is fixedly connected with the deodorization box 1, and an air inlet 8 is arranged below the air pump 3, and the air inlet 8 passes through the deodorization box 1. The upper surface is installed inside the dust-suppression pool 2. The end of the elbow 4 is connected with a gas-collecting hood 5. A fixing plate 6 for fixing the gas-collecting hood 5 is insta...

Embodiment 2

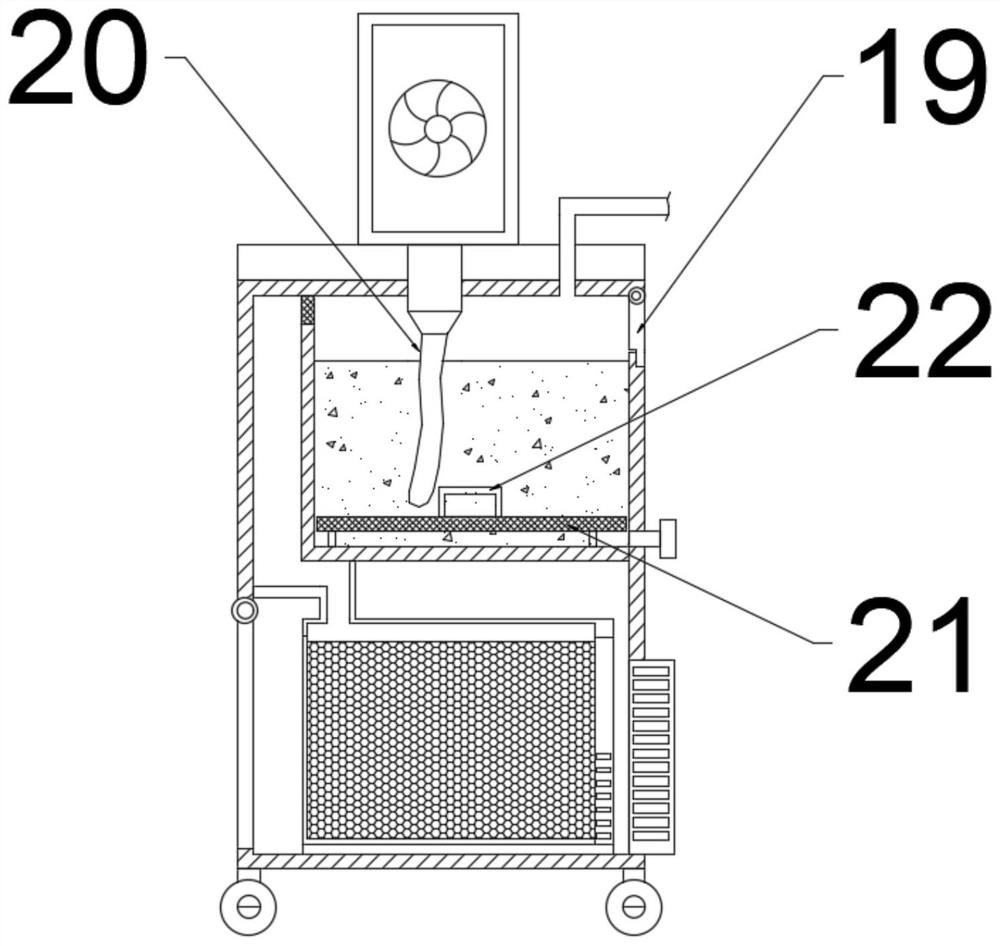

[0028] see image 3 , a textile equipment odor removal device, the main structure of which is the same as that of Example 1, the intake pipe 8 in Example 1 is replaced by a hose 20, the lower end of the hose 20 is placed inside the dust suppression pool 2, and the bottom of the dust suppression pool 2 is set There is a net plate 21, and the net plate 21 is slidingly matched with the inner wall of the dust-suppression pool 2. A handle 22 is arranged above the net plate 21, and the handle 22 is fixedly connected with the net plate 21. A pull plate 19 is arranged on the upper right corner of the dust-suppression pool 2, and the pull plate 19 passes through a hinge. Connect with deodorizing box 1 activity.

[0029] The working principle of the present invention is: when excessive cotton dust has accumulated in the aqueous solution inside the dust-removing pool 2 and affects the purification of odor gas, the staff first opens the blowdown valve 11 to allow the liquid phase of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com