Ginned cotton humidifier

A humidifier and lint technology, applied in textiles and papermaking, fiber treatment, packaging, etc., can solve problems such as increasing moisture regain, increasing packaging difficulty, increasing safety hazards, etc., to achieve the effect of increasing moisture regain and enhancing the activity of water molecules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

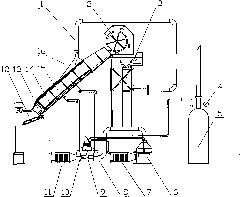

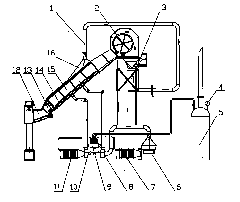

[0022] Refer to attached figure 1 , which shows a lint humidifier, including a cotton feeding channel 15 arranged obliquely downwards connecting the cotton feeding device 12 and the cotton dust basket 3 and a humidifying device for humidifying the lint flowing through the cotton feeding channel, the humidifying The equipment includes a humidification grille assembly 14 arranged in the cotton delivery passage and a steam device connected to the humidification grille assembly via a humidification blower 8 and a configured pipeline. Among them, the cotton dust cage is a device for enriching lint in the packaging equipment, and the noodle feeding device is a device directly connected to the packaging equipment. Naturally, based on this consideration, those skilled in the art may also apply these two devices to this plan In general, this is just a simple element transformation.

[0023] Regarding the moisture regain of lint, under the condition that the predetermined temperature i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com