Dust removal equipment for anti-static cotton processing

A kind of dust removal equipment and anti-static technology, which is applied in the field of dust removal equipment for anti-static cotton cloth processing, can solve the problems of a lot of time spent and low dust removal efficiency, and achieve the effect of improving dust removal effect, dust removal speed and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

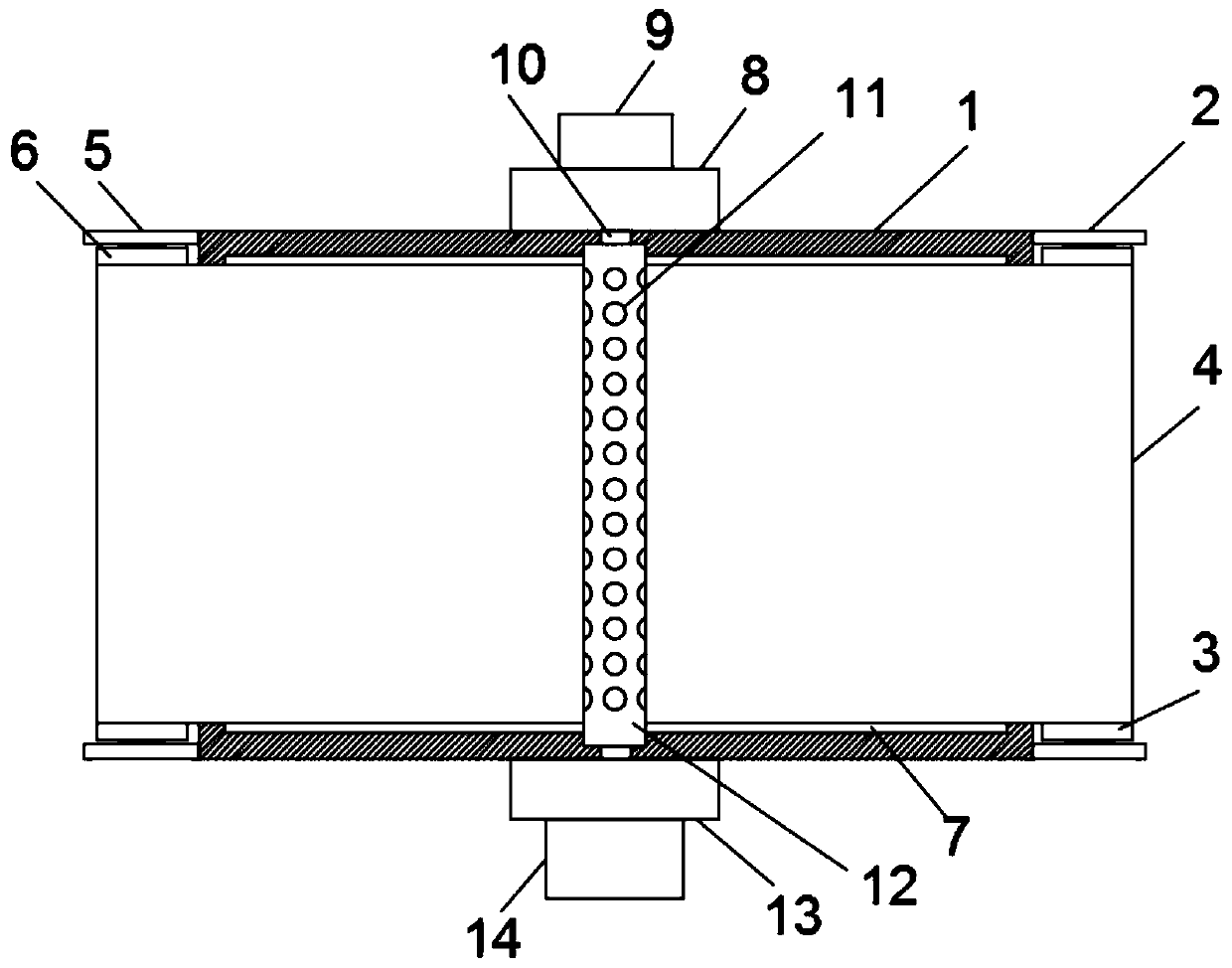

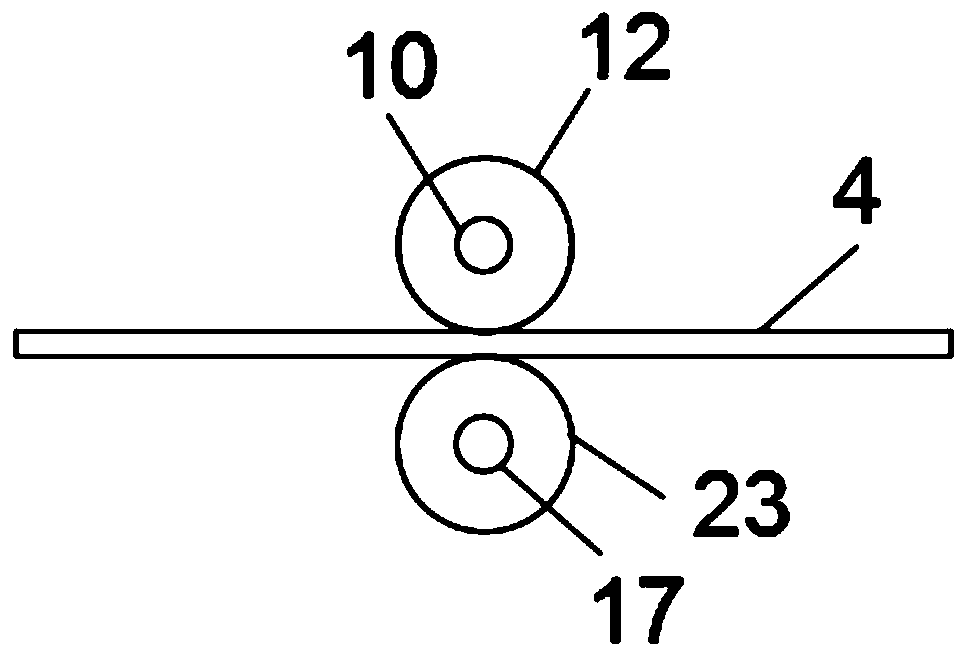

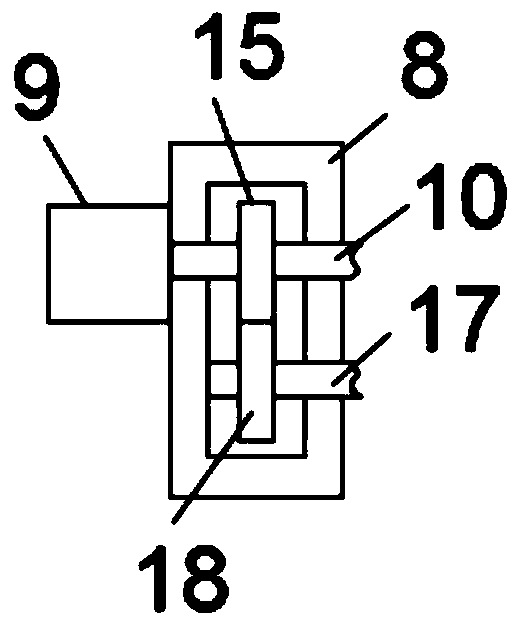

[0027] refer to Figure 1-4 , a dust removal device for anti-static cotton cloth processing, including a workbench 1, an opening 7 is opened on the workbench 1, a second mounting frame 5 is fixedly connected to the left side of the workbench 1, and a puter is connected to the second mounting frame 5 in rotation. The material roller 6 is fixedly connected with the first installation frame 2 on the right side of the worktable 1, and the first installation frame 2 is rotatably connected with the material receiving roller 3. The material receiving roller 3 is driven by a servo motor, and the material receiving roller 3 and the discharging roller Cotton cloth 4 is wound between 6, and one side of workbench 1 is fixedly connected with transmission chamber 8, and drive motor 9 is fixedly installed on transmission chamber 8, is provided with transmission mechanism in transmission chamber 8, and transmission mechanism comprises driving gear 15 and from Driven gear 18, driving gear 15 i...

Embodiment 2

[0031] refer to Figure 5-6, a dust removal device for anti-static cotton cloth processing, including a workbench 1, an opening 7 is opened on the workbench 1, a second mounting frame 5 is fixedly connected to the left side of the workbench 1, and a puter is connected to the second mounting frame 5 in rotation. The material roller 6 is fixedly connected with the first installation frame 2 on the right side of the worktable 1, and the first installation frame 2 is rotatably connected with the material receiving roller 3. The material receiving roller 3 is driven by a servo motor, and the material receiving roller 3 and the discharging roller Cotton cloth 4 is wound between 6, and one side of workbench 1 is fixedly connected with transmission chamber 8, and drive motor 9 is fixedly installed on transmission chamber 8, is provided with transmission mechanism in transmission chamber 8, and transmission mechanism comprises driving gear 15 and from Driven gear 18, driving gear 15 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com