Dedusting method and device for high-temperature smoke

A dust removal device and fume technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of desoldering cracking, safety accidents, loss of personnel in material production, etc., so as to reduce the cost of equipment maintenance and ensure continuous The effect of carrying out and avoiding safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

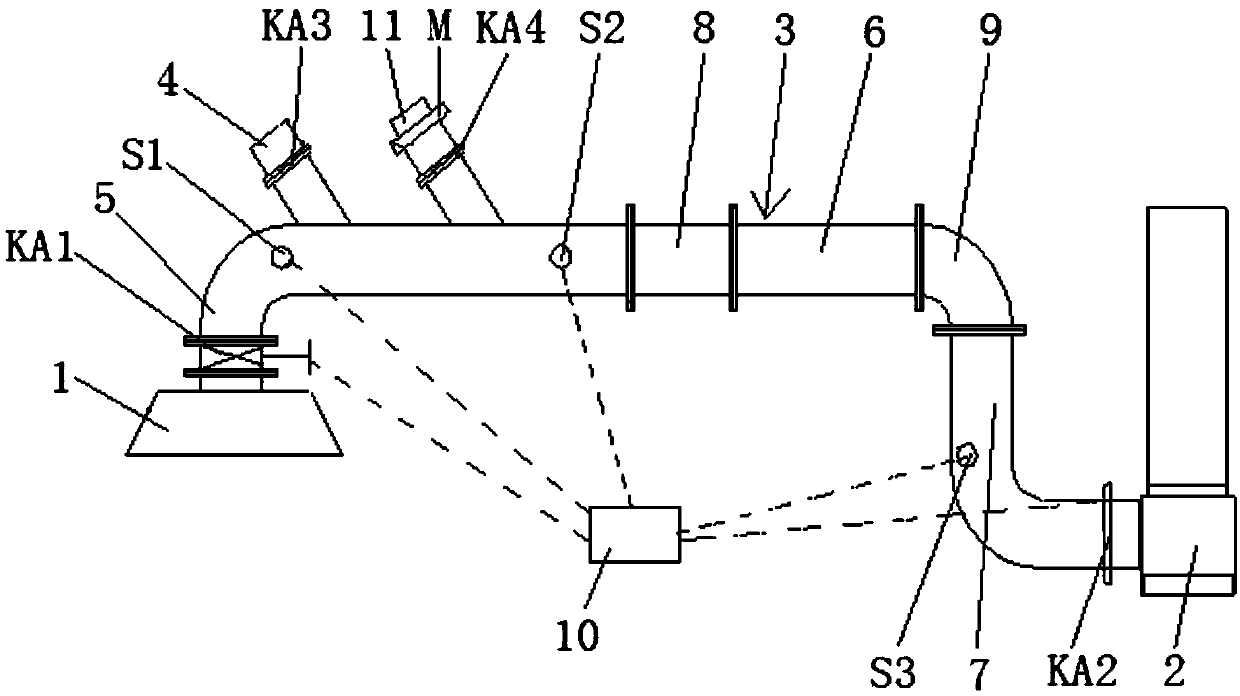

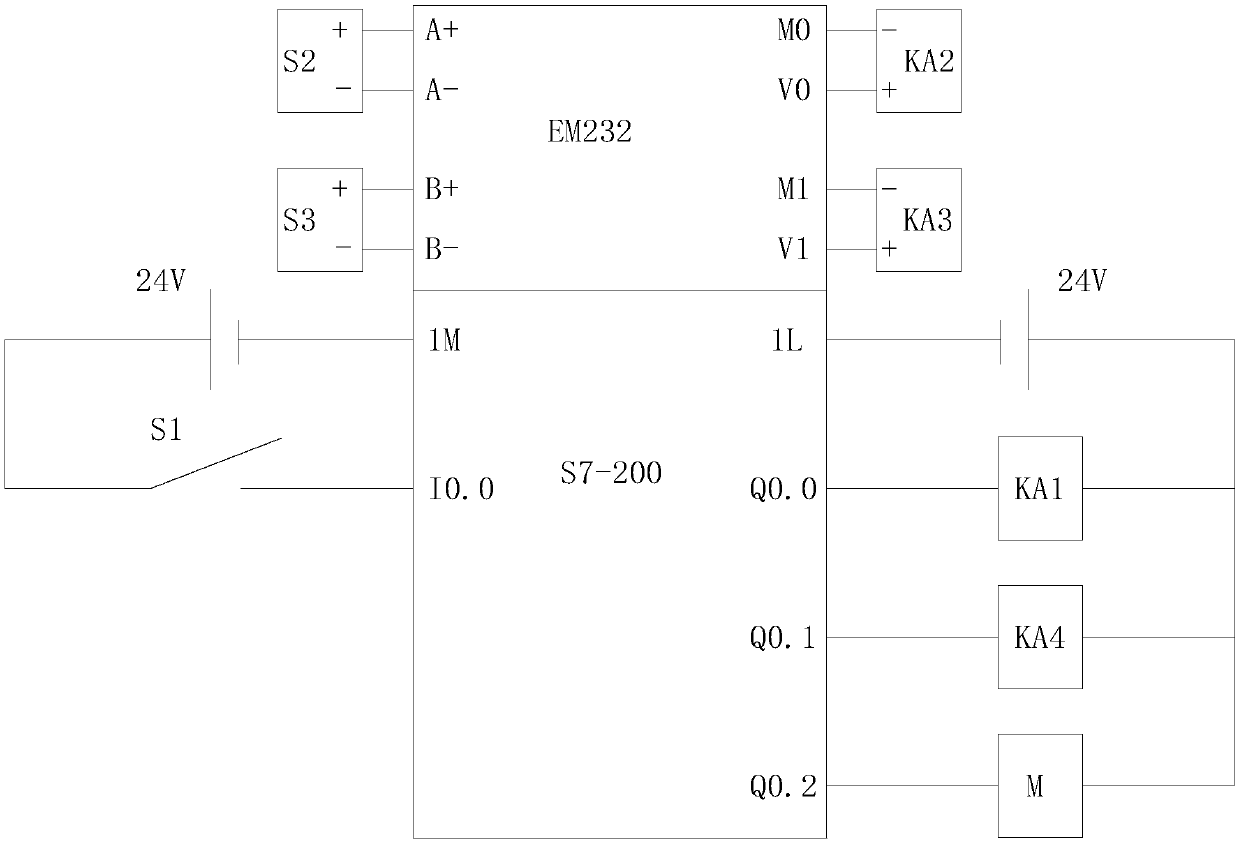

[0021] refer to Figure 1-2 , a high-temperature smoke and dust removal method, the method is to use the dust collection hood 1 to collect the smoke and dust, and transport the smoke and dust to the purification and dust removal system 2 through the pipeline 3 for dust removal, and detect the concentration of combustible substances in the pipeline 3 in real time. When the concentration exceeds the preset When the concentration range is set, the first protective gas is added to the pipeline 3 at a preset injection angle to restore the concentration to the preset concentration range. In this embodiment, the combustible substance is CO, and the first protective gas is flame-retardant Gas, such as nitrogen, the first protective gas can also be compressed air, the preset injection angle is the angle between the first protective gas injection dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com