An environmentally friendly efficient desulfuration dust collector

A desulfurization dust collector and dust collector technology, applied in chemical instruments and methods, dispersed particle filtration, use of liquid separators, etc., can solve the problem of incomplete dust removal in the dust collector, and achieve enhanced spray desulfurization effect, good effect and resistance. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

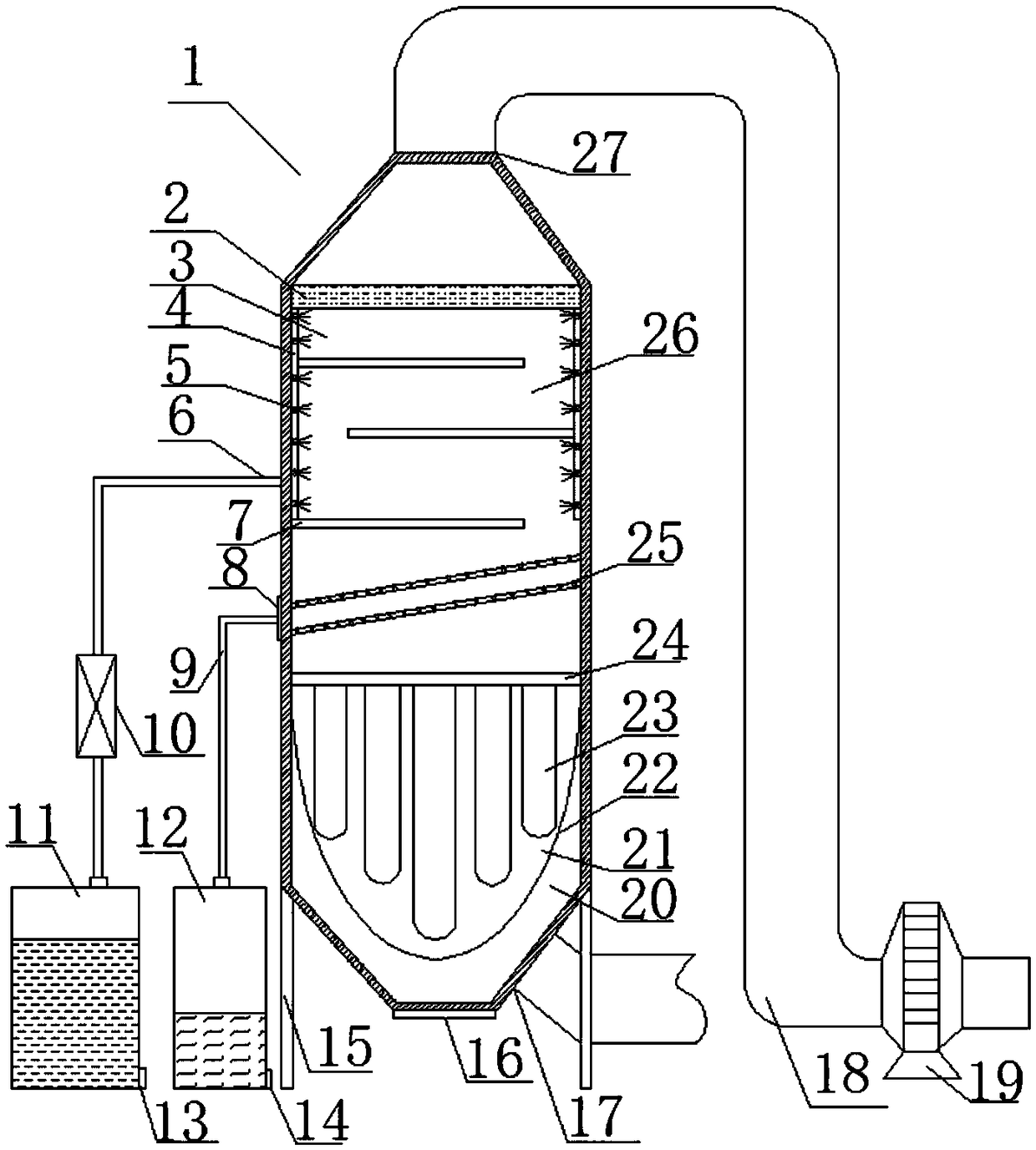

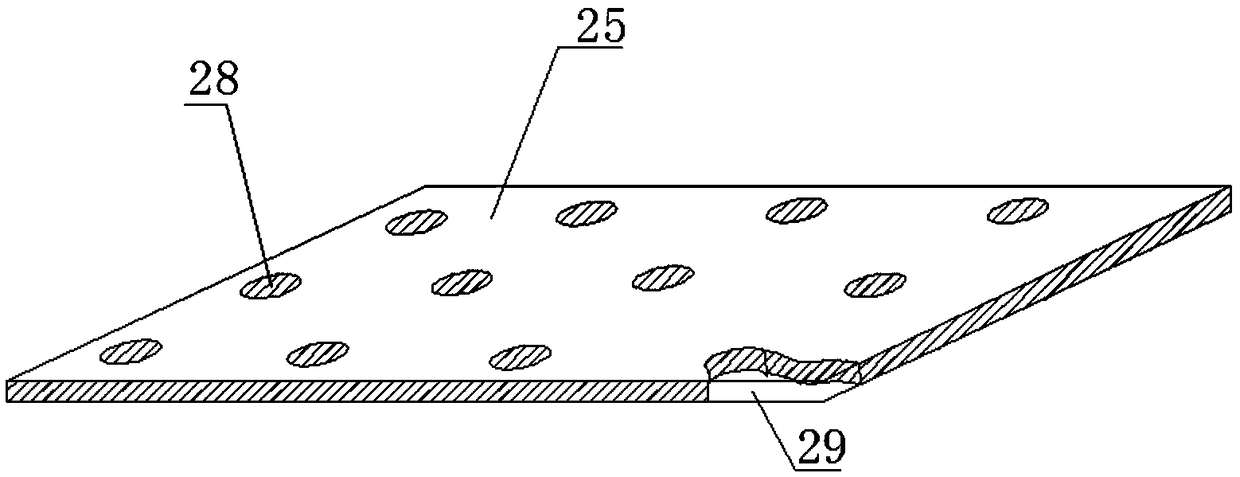

[0030] Such as figure 1 As shown, an environmentally friendly and efficient desulfurization dust collector includes a dust collector body 1 and a support frame 15, and is characterized in that: the bottom of the dust collector body 1 is provided with an air inlet 17 and a dust outlet 16, and the top is provided with an air outlet 27, The air outlet 27 is connected to the fan 19 through the gas pipeline 18, and the dust collector body 1 includes a bag dust removal chamber 20, a spray chamber 3 and a packing layer 2 from bottom to top, and the bag dust removal chamber 20 and the spray chamber 3 are separated by inclined air-permeable plates 25, and the bag filter 21 is fixedly installed on the inner wall of the bag dust removal chamber 20, and several spray pipes 4 are fixedly installed on the inner walls of the spray chamber 3, and Several nozzles 5 are arranged on the spray pipes 4 .

[0031] The working principle and process of this technical solution are as follows:

[003...

Embodiment 2

[0035] According to Example 1, such as figure 1 As shown, the cloth bag filter 21 includes a large cloth bag 22 and a cloth bag bracket 24 fixedly connected to the inner wall of the bag dust removal chamber 20. Several small cloth bags 23 are also arranged in the large cloth bag 22, and the large cloth bag 22 and the small cloth bag The cloth bags 23 are all combined and fixed by the cloth bag bracket 24. The cloth bag filter 21 is provided with two layers of cloth bags, large and small, which can effectively enhance the filtering effect.

Embodiment 3

[0037] According to Example 1, such as figure 1 As shown, any two pairs of sides of the inner wall of the spray chamber 3 are fixedly connected with a plurality of partitions 7 that divide the spray chamber 3 into S-shaped gas passages 26 . The S-shaped gas channel 26 separating the spray chamber 3 can prolong the path and time for the gas to pass through the spray chamber 3, effectively enhancing the desulfurization effect of the spray.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com