Automatic dust removal device for pole piece

A technology of automatic dust removal and vacuuming device, applied in cleaning devices, removing smoke and dust, transportation and packaging, etc., can solve the problems of high battery short circuit rate, battery short circuit, easy secondary pollution, etc., to prevent secondary pollution products. , Prevent impurities from flying and improve the effect of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

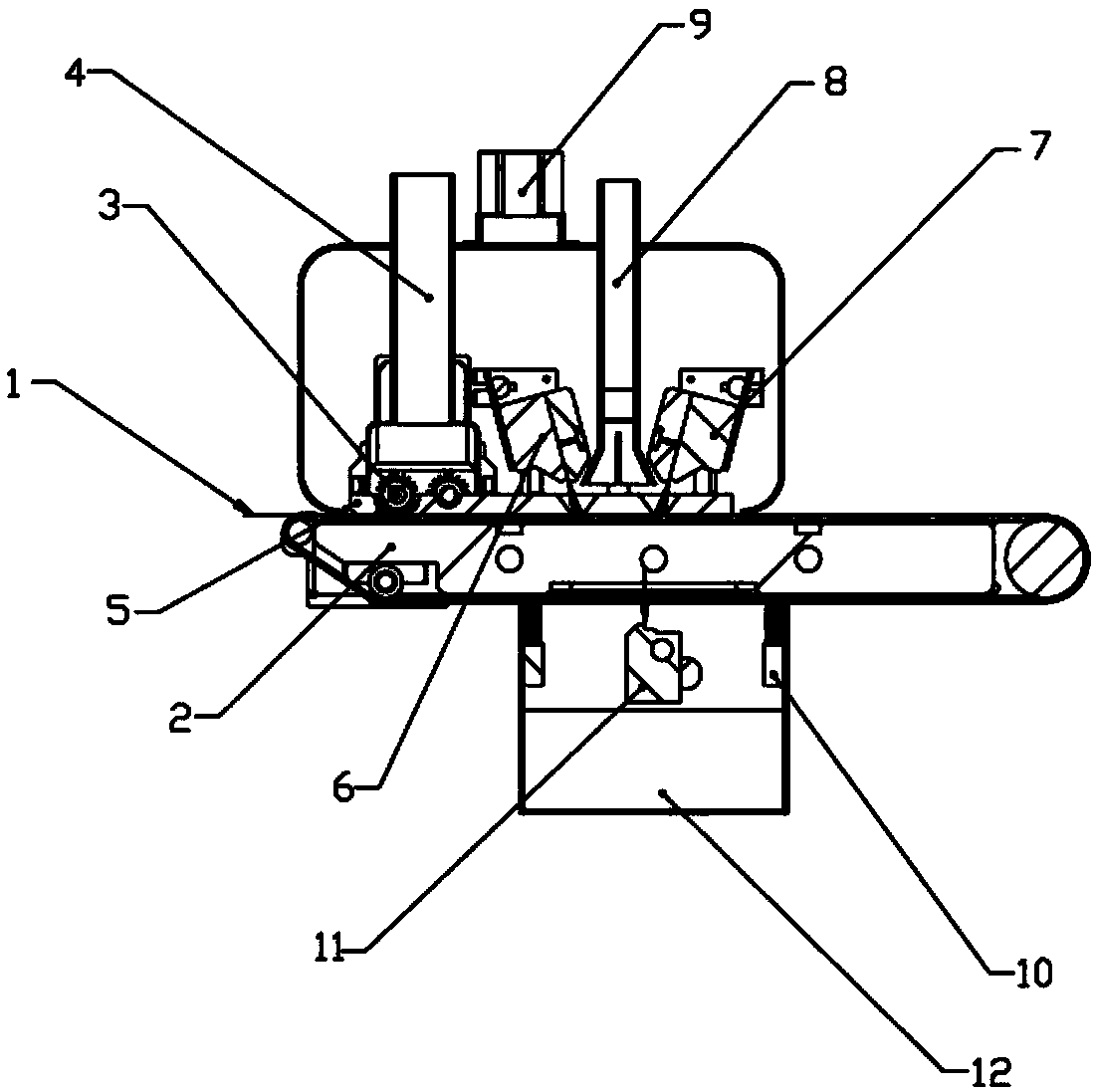

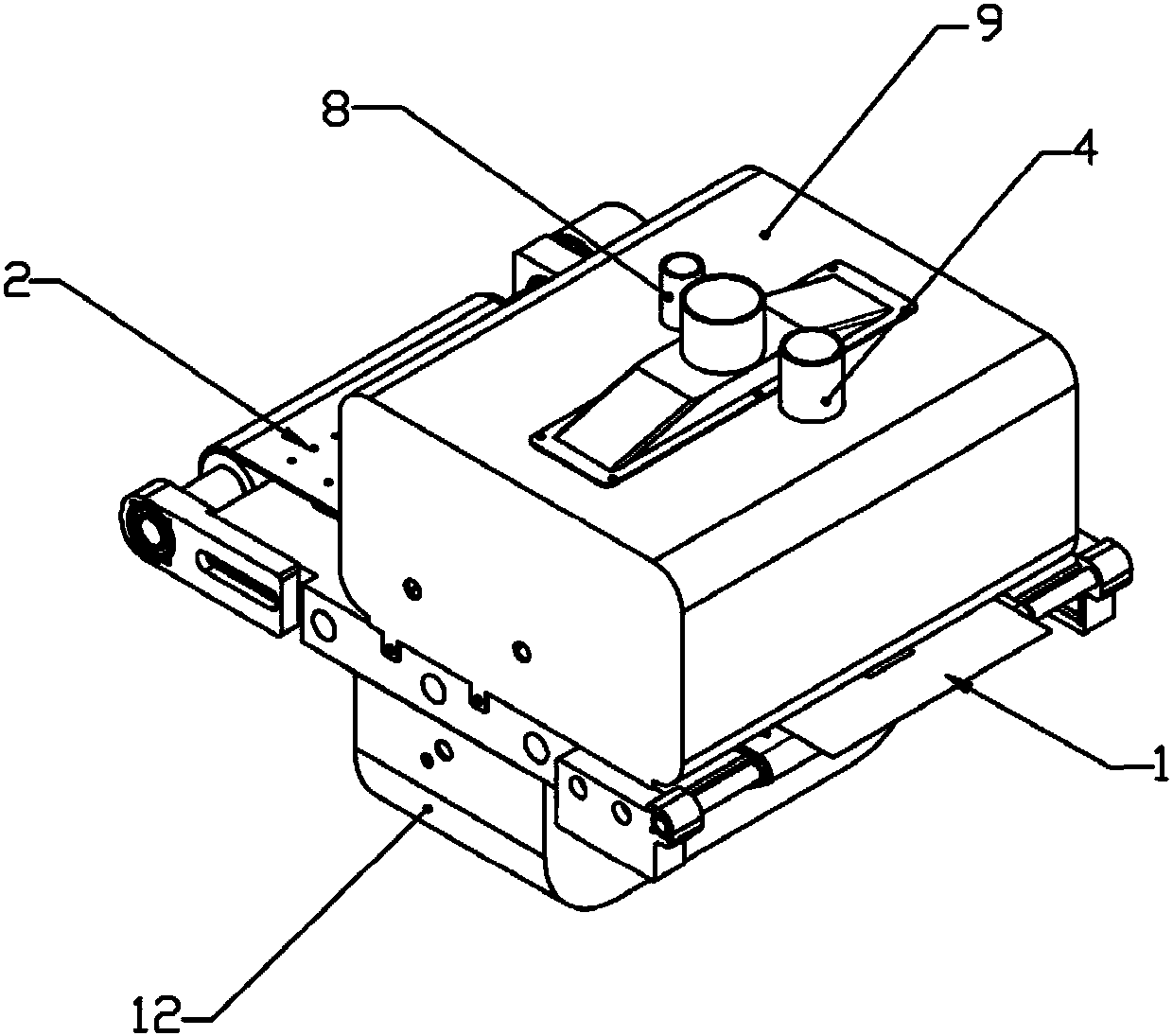

[0017] In order to facilitate the understanding of those skilled in the art, the following embodiments and appendices are combined Figure 1-2 The present invention is further explained, and the content mentioned in the embodiments does not limit the present invention.

[0018] Such as figure 1 with 2 As shown, the present invention relates to an automatic pole piece dust removal device, which includes a housing 9 and a vacuum conveyor belt 2 passing through the housing 9. Brushes are sequentially arranged above the vacuum conveyor belt 2 along the transport direction of the pole pieces 1. A powder suction device, a powder blowing and dust suction device, a self-cleaning device is arranged under the vacuum conveyor belt 2; the powder brushing and dusting device and the powder blowing and dusting device are both arranged in the housing 9; The dust-blowing device includes a brush roller 3 located above the vacuum conveyor belt 2 and a first dust-absorbing cavity 4 located above the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com