Device for generating gas and fuel from solid combustible

A gas, solid state technology, applied in the preparation of liquid hydrocarbon mixtures, petroleum industry, special forms of dry distillation, etc., can solve problems such as high operating costs, low gas calorific value, and scrapping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

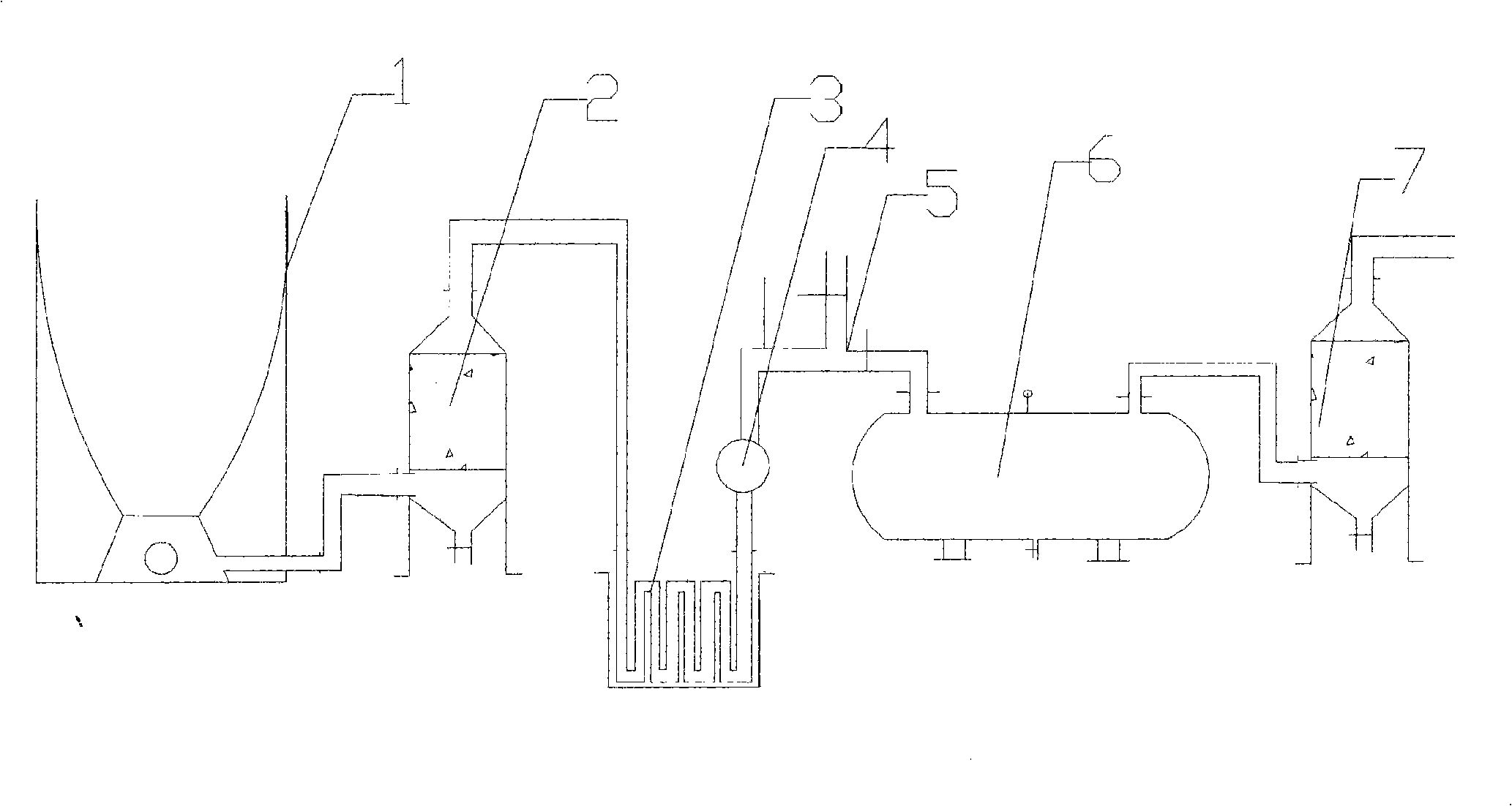

[0012] In conjunction with the accompanying drawings and specific examples for further explanation:

[0013] According to the shape of solid combustible material, make gasification furnace 1, the inner diameter of gasification furnace 1 is 2 meters, width is 0.6 meters, insulation layer thickness is 30 centimeters, and the ratio of external dimension length to width is 2:1. The interior is built with refractory bricks, and the gas outlet and ash outlet are under the grate. The fire grate is made of refractory material, and the gap between the fire grate and the fire grate is 3-5 cm. The dust filter 2 is a conical shape with two pointed ends, made of metal, the air outlet is on the top, the air inlet is on the bottom, and the middle is dust removal particles with a diameter of 1--2 cm. The tar in it is pyrolyzed and gasified again. The gas enters the dust filter 2 through the air intake pipe, and the ash powder is blocked by the dust removal particles and falls in the dust ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com