Horizontal centrifugal mist eliminator

A mist eliminator and horizontal technology, which is applied in the field of exhaust gas purification and treatment, can solve the problems of lack of mist removal effect and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

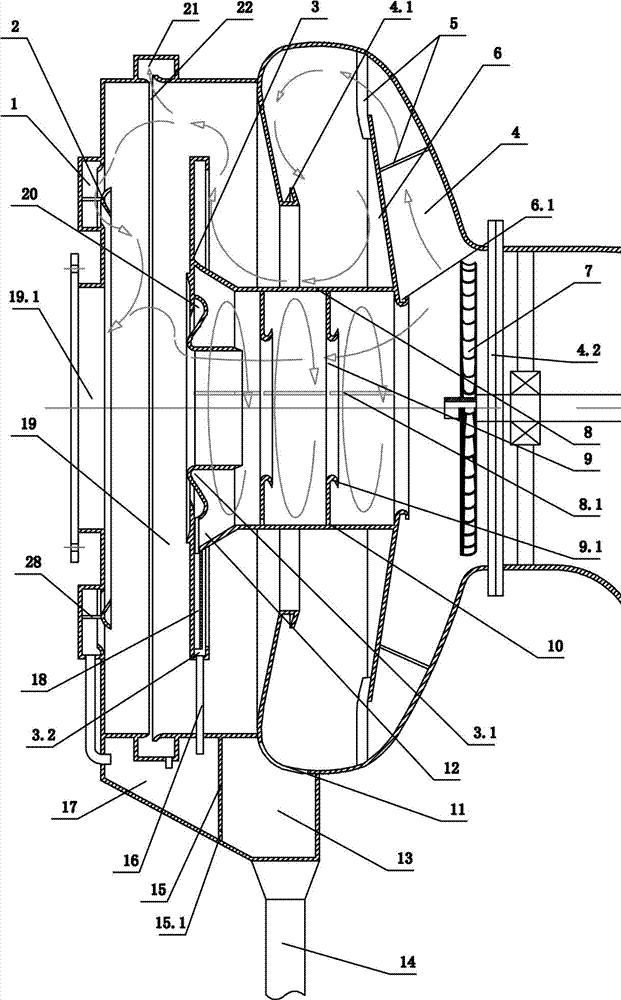

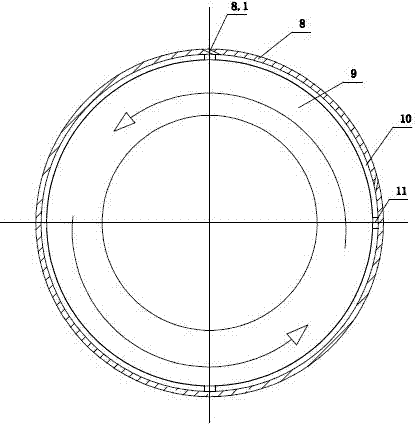

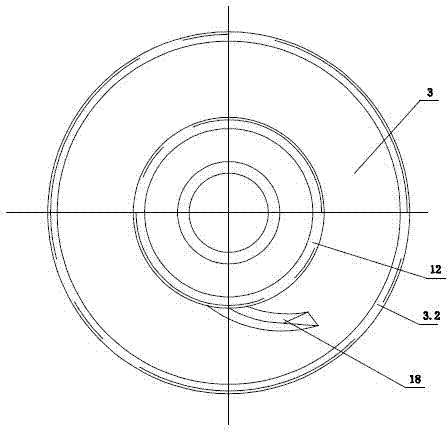

[0021] Such as figure 1 As shown, the present invention is a horizontal centrifugal mist eliminator for removing water mist in the airflow. The exhaust tank 19 of water tank 4 and rear side. The front side of the water ski tank 4 is provided with an air inlet 4.2, and at the air inlet 4.2 of the water ski tank 4, a rerouting fan blade 7 driven by a motor is installed. After the airflow mixed with water mist passes through the rerouting fan blade 7, Because the water itself has gravity, most of the water mist is thrown around by the diversion fan blade 7, and a small amount of water mist is discharged forward with the air-flow. An air exhaust port 19.1 is provided at the center of the rear end surface of the air exhaust tank 19, and the pure air after demisting by the cylinder is discharged from the air exhaust port 19.1.

[0022] The side wall of the water ski tank 4 diverges in an arc from front to back, the rear side of the water ski tank 4 is recessed inward, and an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com