Stereo distribution and storage conveying device for power and free type suspension conveyer

A technology for hanging conveyors and conveying equipment, applied in the directions of conveyors, transportation and packaging to achieve the effect of improving work efficiency and orderly production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

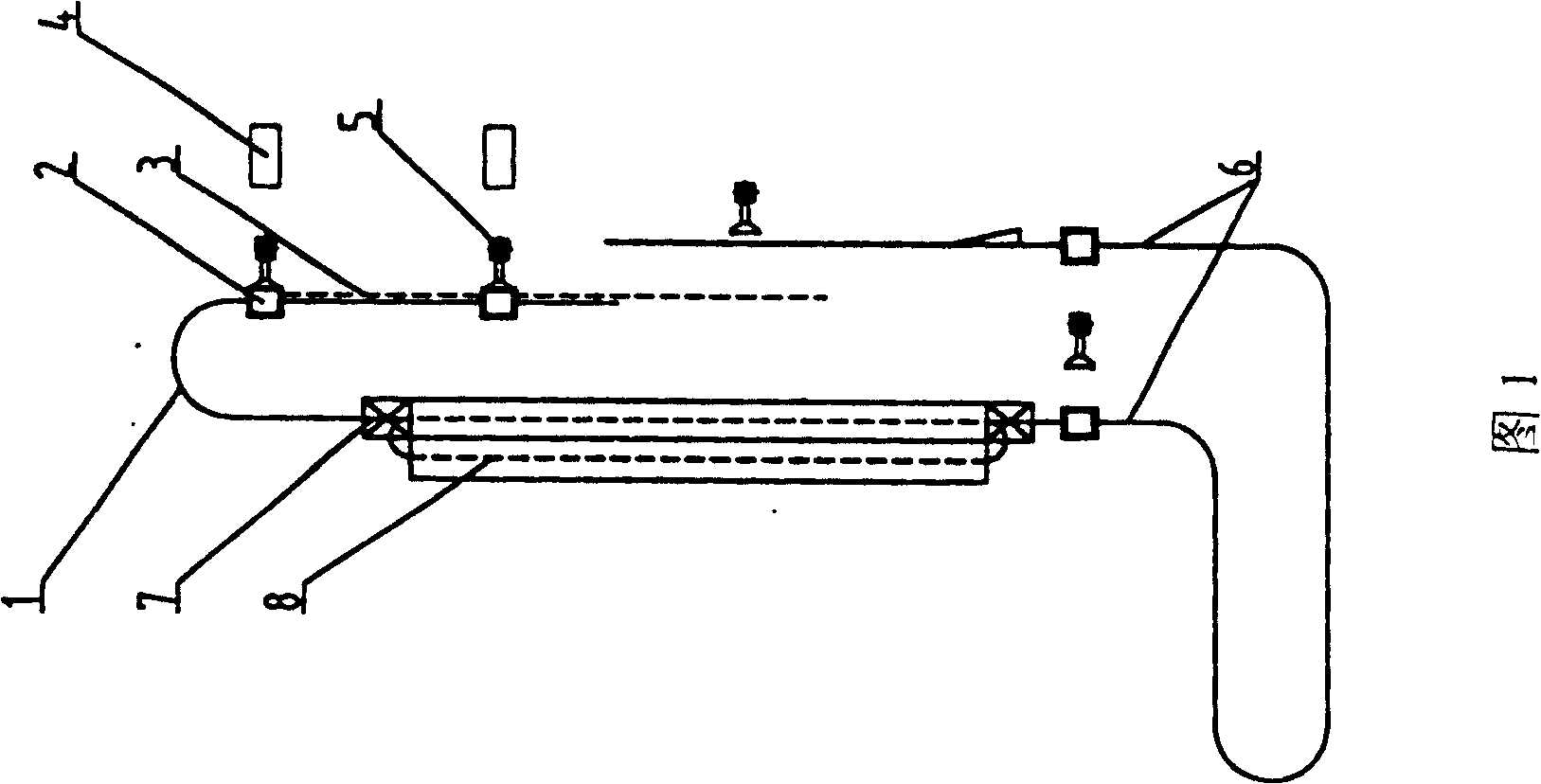

[0008] Referring to the accompanying drawings, the accumulative suspension conveyor line 1 is installed through steel structure welding support, and can be conveyed in a circle. The movable track 2 is connected with the bolts through the chute and installed at the position where the accumulative suspension conveyor line 1 removes the car group, and the third is the vertical vertical conveyor line, one of which is welded and docked with the accumulative suspension conveyor line 1, and the other line body is in common with it. Welded into the same steel structure, the vehicle group and the workpiece can be exchanged to any one of the lines for transportation by lifting and rotating the clamping claw 5 . The two parallel line bodies of the parallel suspension conveyor line 6 are respectively welded and docked with the accumulation suspension conveyor line 1. By connecting the two parallel conveyor lines with bolts and installing the lifting and rotating clamping jaws 5, the workpi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com