Vertical conveying device for accumulation type suspension conveyer assembly

A technology of conveying device and locomotive set, which is applied in the direction of conveyor, transportation and packaging, can solve the problems of complex structure and overall bulkiness, and achieve the effect of reducing production cost, improving work efficiency, and stable and reliable work performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

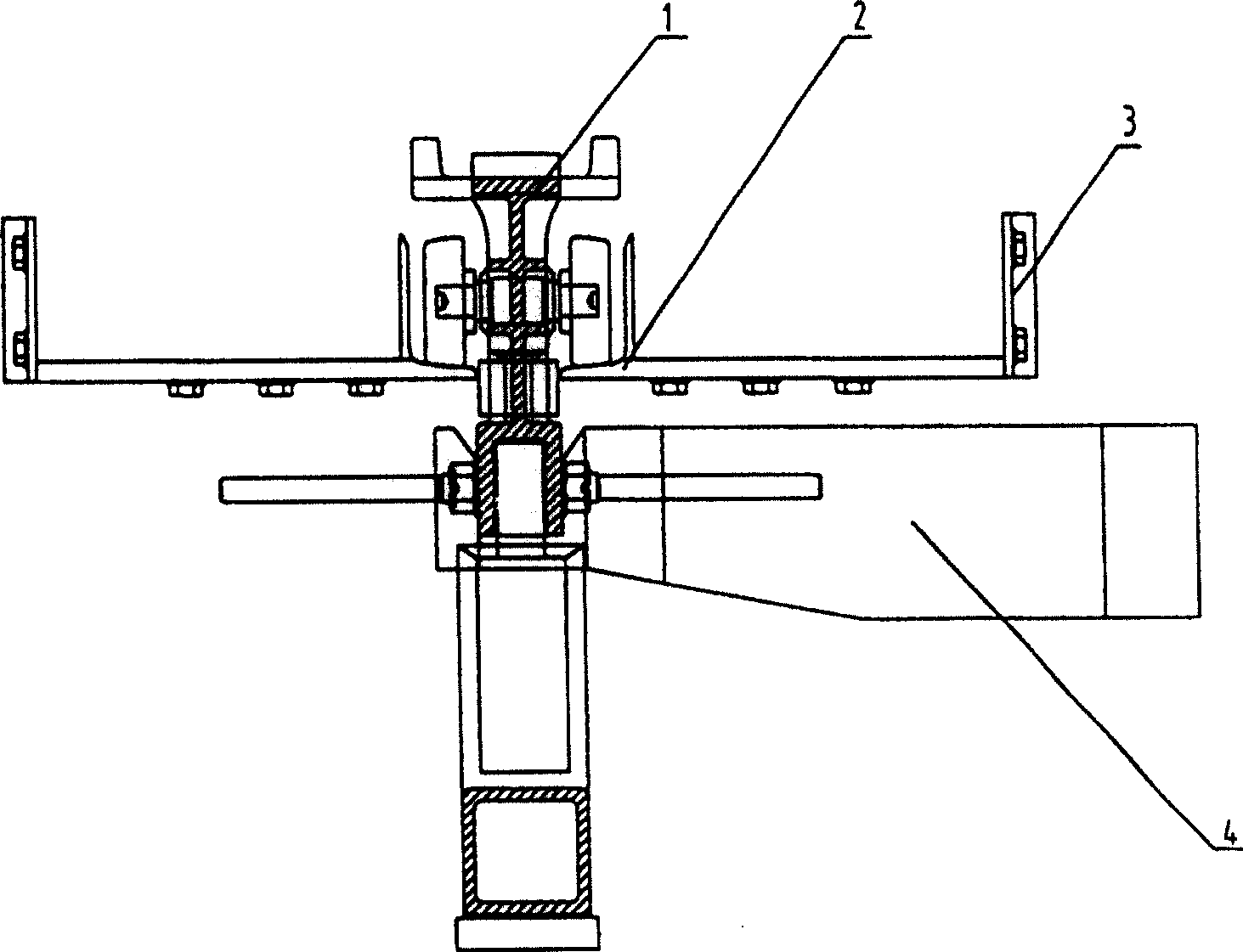

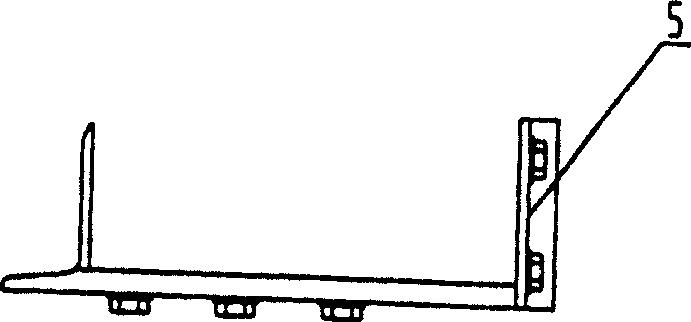

[0010] Control attached figure 1 , 2 , its structure is that the upper and lower stacked suspension conveyor lines 3 and 5 are welded and fixed by steel structure to form a conveyor track, and the movable load rail 2 is connected by the chute opened on the conveyor line by bolts, so as to realize free sliding and free movement in it. The claw head of the lifting and clamping claw 4 can grab the vehicle group 1, and the vehicle group 1 is on the upper stacking suspension conveyor line 3 or the lower stacking suspension conveyor line 5, and the free lifting clamping claw 4 can move freely Or rotation is a necessary mechanism to complete the vertical conveying.

[0011] When working, when the car group 1 is transported from the conveying line to this section, it needs to transfer to the lower conveying line, give a control signal, and freely move the clamping claws of the lifting and clamping claws 4 to the bottom of the trolley of the car group. Rise up and clamp the vehicle g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com