Pepper baking oven

A chili and baking technology, applied in the field of chili processing, can solve the problem of inability to dry large batches of chili, and achieve the effect of reducing enterprise losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

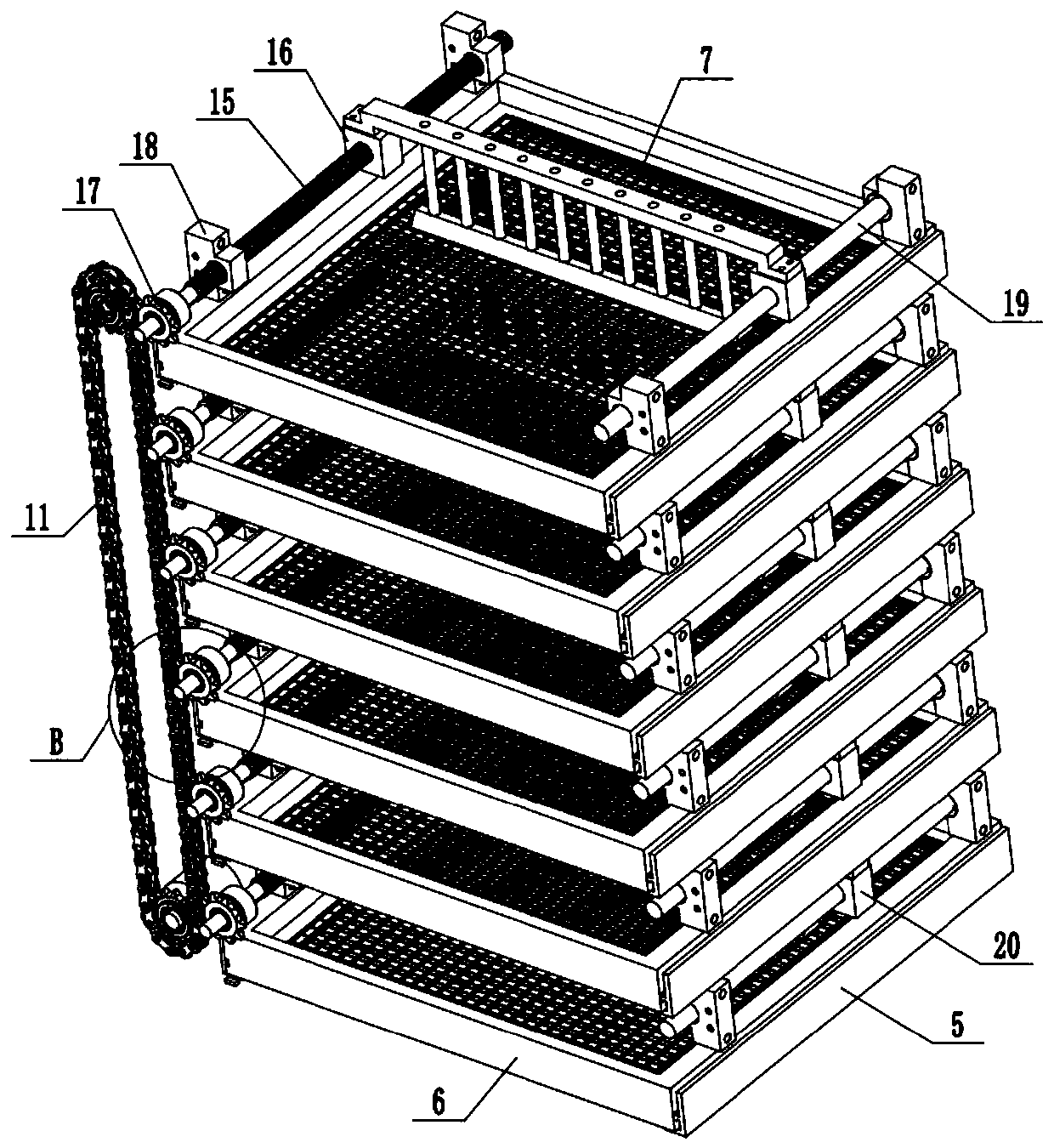

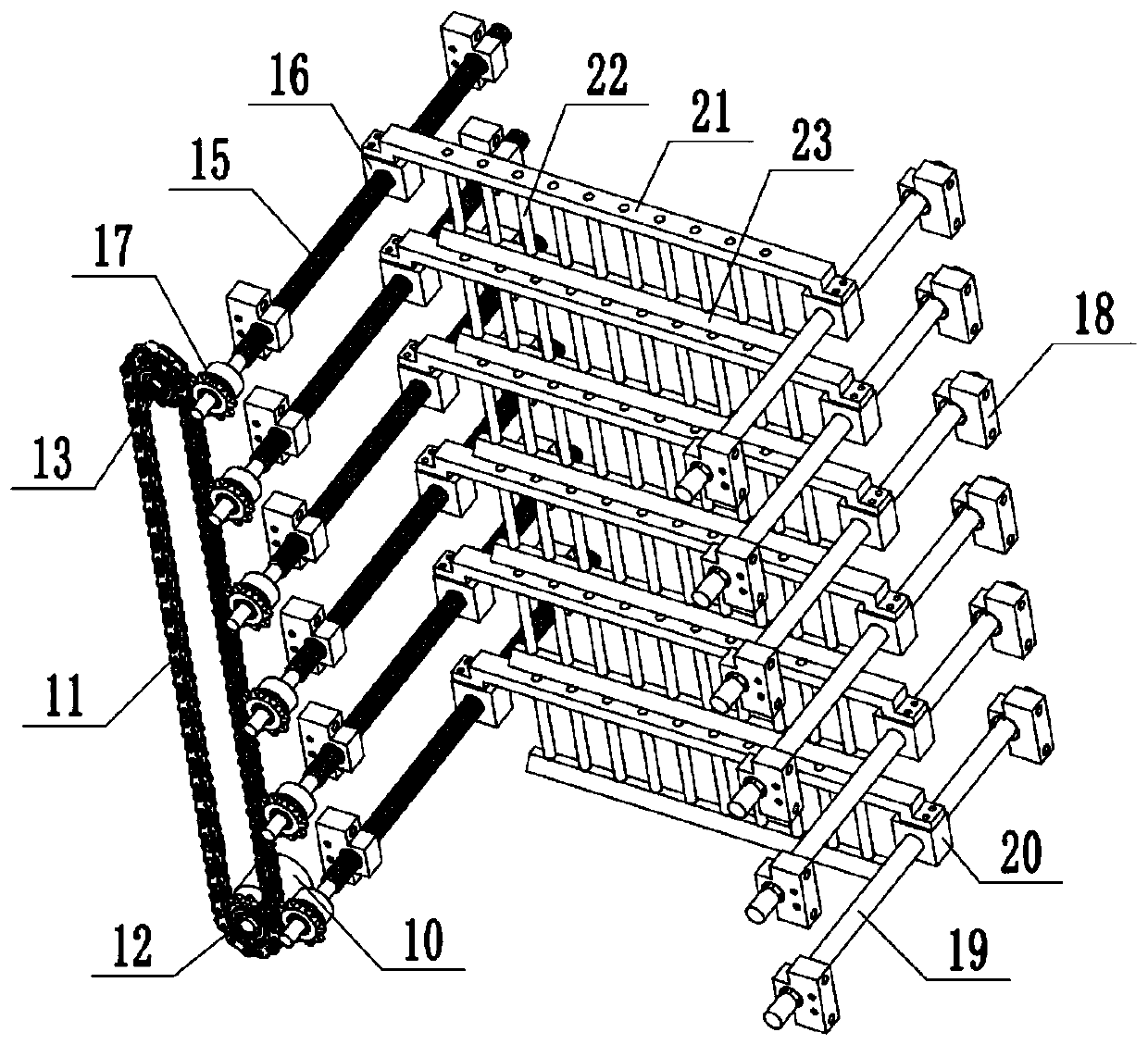

[0040] Embodiment one is basically as Figure 1-Figure 7 As shown, a pepper baking box includes a box body 1 with a baking cavity 2 inside, an opening is provided on the front side of the box body 1, and a box door 3 for sealing the baking cavity 2 is provided at the opening, and the box door 3 is opened. Observation hole 4 is arranged, and transparent quartz glass is fixedly connected with through screw in observation hole 4; The guide plate 5 that is arranged horizontally is fixedly connected with the guide plate 5 that is arranged on the inner wall of left and right sides of baking cavity 2 by screw, and the rear end of guide plate 5 and baking The rear inner walls of the cavity 2 are offset, and the number of guide plates 5 on each side wall on the left and right sides of the baking cavity 2 is six. The plate 5 forms a placement groove, and the tray 6 for adorning the peppers to be baked can be put into the placement groove.

[0041] Such as Figure 4 As shown, the tray ...

Embodiment 2

[0053] The difference between the second embodiment and the first embodiment is that a universal roller with a brake is installed on the bottom of the box body 1, so that the pepper baking box can be pushed to the corresponding position, and at the same time, as Figure 8 As shown, a handle 25 is welded on the front side of the tray 6, which is convenient for putting the tray 6 into or extracting from the placement slot, and there is a groove 26 on the rear side of the top surface of the tray 6, so that when the pepper is baked, it is convenient to put the tray 6 The chili in the interior is poured out by the bevel 26, and after the bevel 26 is set simultaneously, the stirring rod and the stirring block can be inserted into the tray 6 more conveniently.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com