Door production system and method and refrigerator door matching system of refrigerator production line

A production system and production line technology, applied in the direction of transportation and packaging, storage devices, conveyors, etc., can solve the problems of large floor area, irregular placement, waste of manpower, etc., to save manpower and material resources, simple and efficient matching, judgment high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

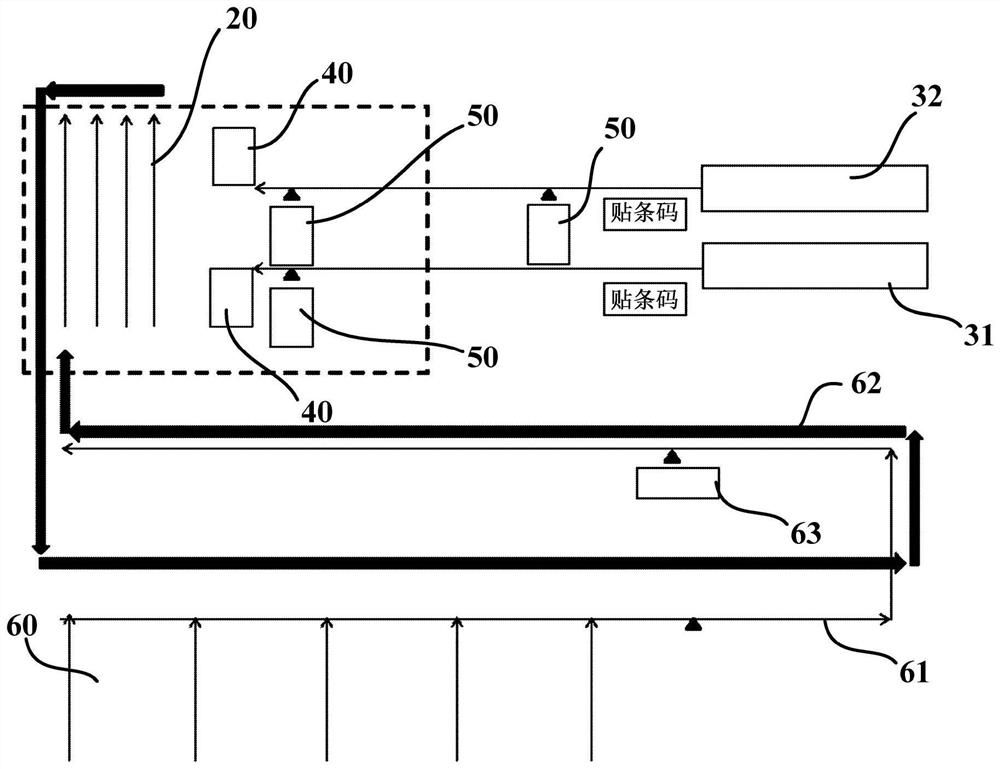

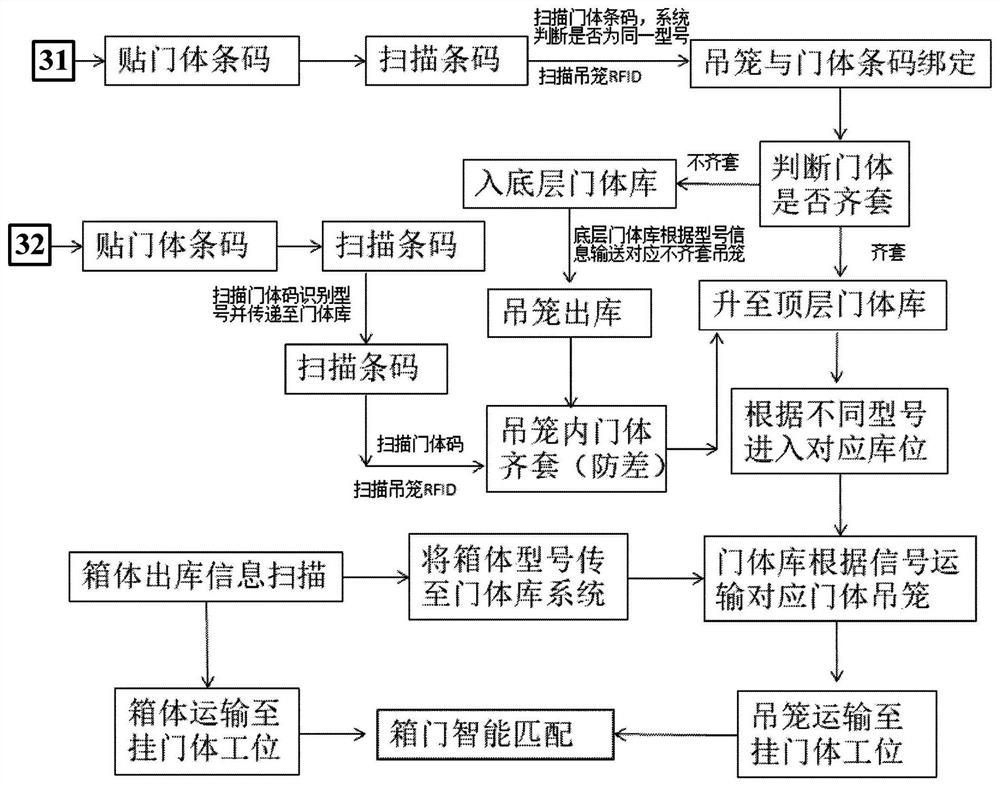

[0043] An embodiment of the present invention provides a door body production system for a refrigerator production line. figure 1 It is a schematic structural diagram of a door matching system of a refrigerator production line according to an embodiment of the present invention, which has a door body production system. The door body production system in this embodiment at least includes: a door body warehouse 20, a first door body production station 31, a second door body production station 32 and a cage system.

[0044] The door body library 20 may have a first collection space and a second collection space. The door body storage 20 is arranged at a certain height from the ground, and can have double or multiple layers. The space on the bottom floor can be the second storage space, and the rest of the space can be the first storage space. The door body warehouse 20 can be used to set up other parts of the refrigerator production line, or set up the first door body production...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com