Corrugated tubular material with winding structure and strip material thereof

A corrugated and strip technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the limited bearing capacity of hollow stiffeners, increase the force of the backfill layer on the hollow stiffeners, and the inner rib to enhance the outer corrugation. It can solve the problems such as subsidence of the wall pipe of the plastic wrapping structure, and achieve the effect of reducing the production process and improving the rigidity of the ring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

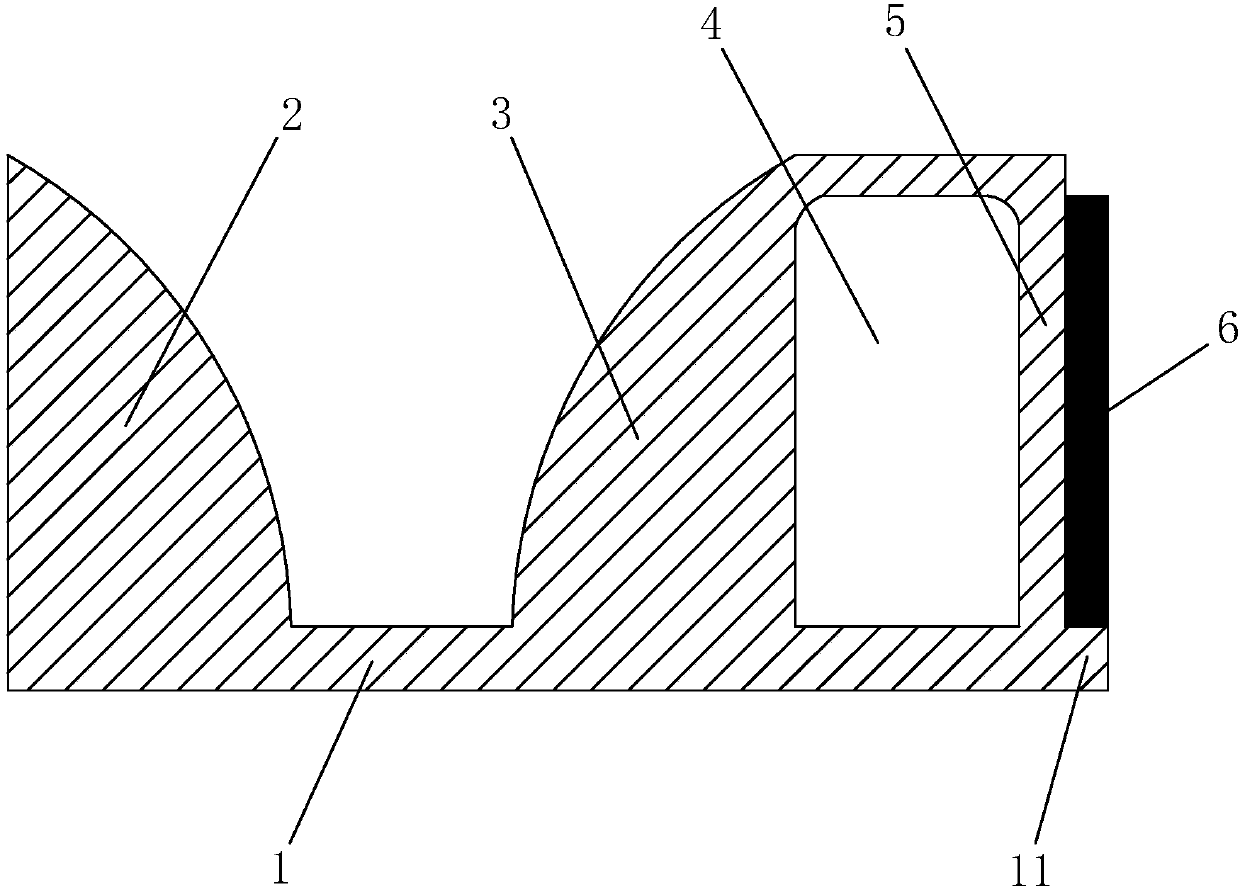

[0040] Embodiment one: a kind of tape, such as figure 1 As shown, including the negative film 1, the left solid convex part 2 and the right solid convex part 3 are integrally connected respectively on both sides of the negative film 1, the heights of the left solid convex part 2 and the right solid convex part 3 are the same, and the two opposite sides are Arc, and the side away from it is perpendicular to the negative film 1. The left end surface of the left solid convex part 2 is flush with the left end surface of the negative film 1, and the right end surface of the right solid convex part 3 is connected with a support rib 5 arranged perpendicular to the negative film 1. The bottom end of the support rib 5 is fixedly connected with the bottom sheet 1, and the top end of the support rib 5 extends to the top of the right solid convex part 3 and is fixedly connected. A cavity 4 is formed between the support rib 5 and the right solid convex portion 3 . The right end of the bo...

Embodiment 2

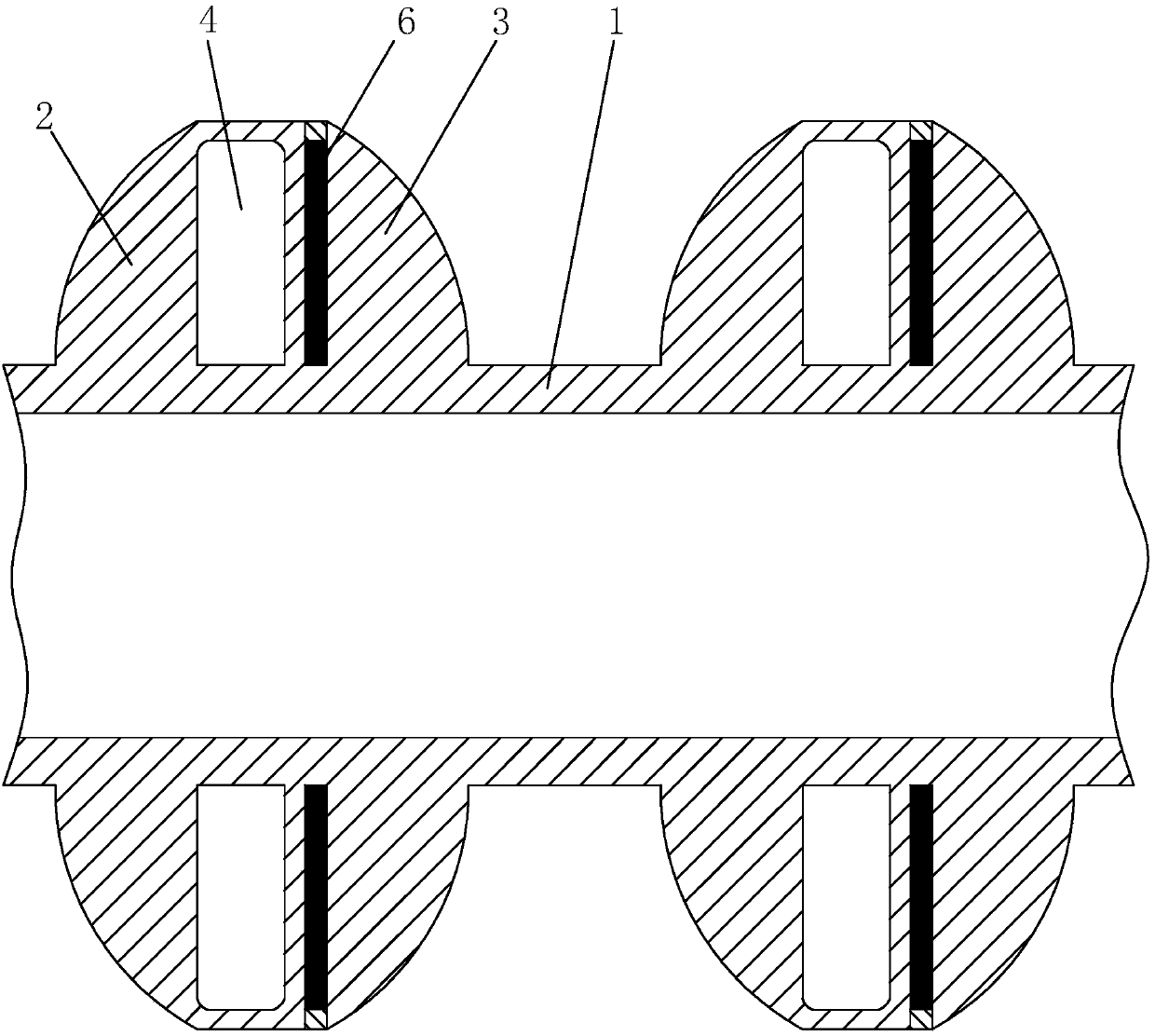

[0060] Embodiment two: a kind of tape, such as Figure 4 As shown, the difference from Example 1 is that the combination figure 1 , the same cavity 4 and support rib 5 are provided on the end face of the left solid convex part 2 . refer to Figure 5 and Figure 6 , the highest point of the corrugated pipe formed after the strip is wound is at the junction of the two supporting ribs 5, so that the surface ribs of the corrugated pipe form a solid-hollow-supporting rib 5+metal sheet 6-hollow-solid cycle structure, metal The sheet 6 increases the strength of the support rib 5 in the middle, increases its bearing capacity, and reduces the possibility of sagging in the middle. The connection area between the solid parts at both ends and the pipe wall is increased, which reduces the possibility of the connection being torn when the force is applied.

Embodiment 3

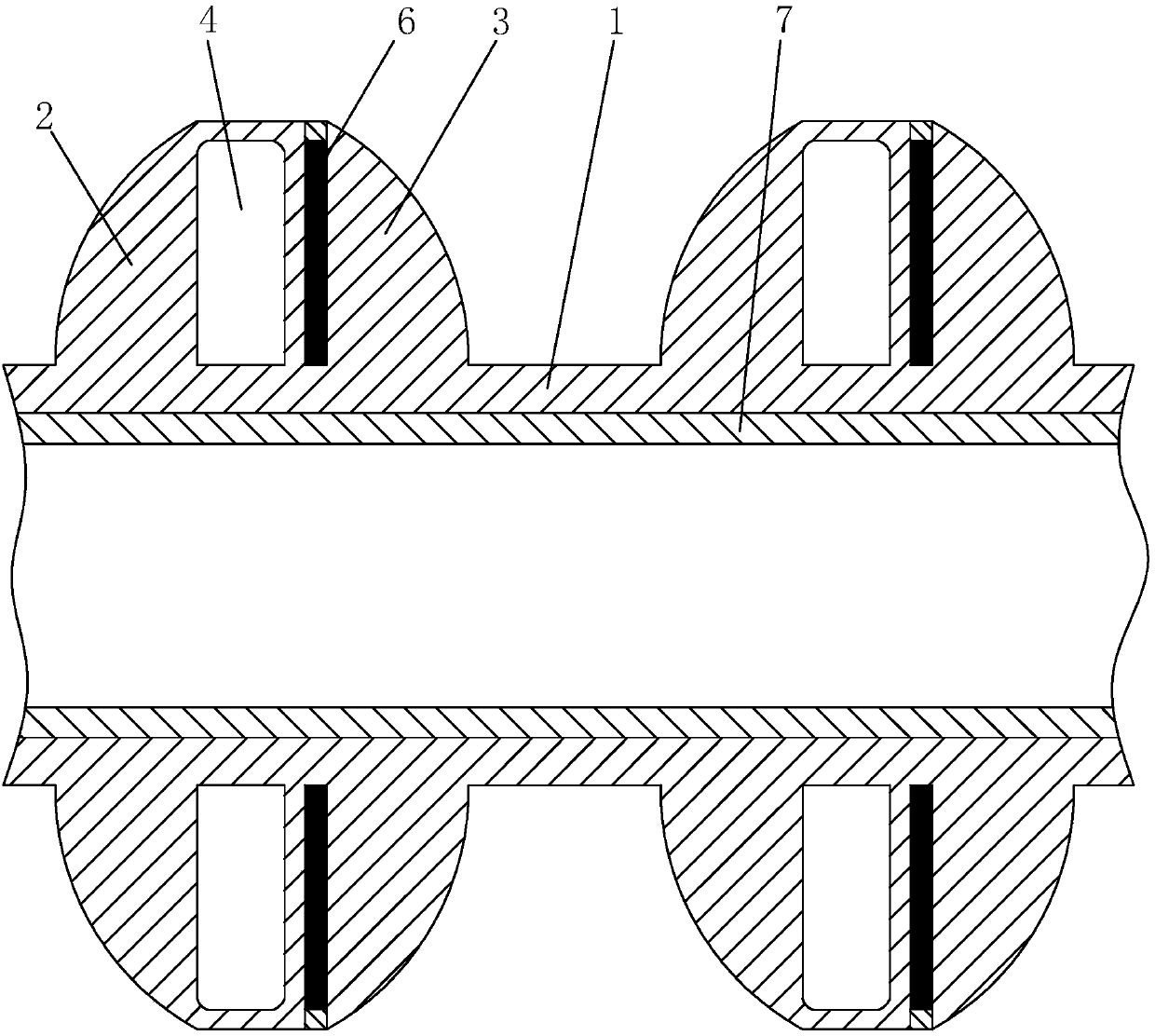

[0061] Embodiment three: a kind of tape, such as Figure 7 As shown, the difference from Example 2 is that the combination Figure 4 , the arc-shaped left solid convex portion 2 and the right solid convex portion are replaced with a trapezoidal convex portion 8 . refer to Figure 8 and Figure 9 Compared with the second embodiment, the advantage is that the top of the ribs on the surface of the bellows is flat, and the height of the supporting ribs 5 and metal sheets 6 in the middle is the same as that of the solid parts on both sides, which together play a supporting role and reduce the support in the middle Rib 5 and metal sheet 6 may be folded by external force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com