Ceramic tile temporary tile storage warehouse of ceramic tile packaging assembly line and ceramic tile lifting method

A packaging line and ceramic tile technology, applied in the direction of packaging, transportation and packaging, packaging item types, etc., can solve the problems of economic loss, packaging speed lag, waste of resources, etc., to improve accuracy and reliability, high reliability, good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

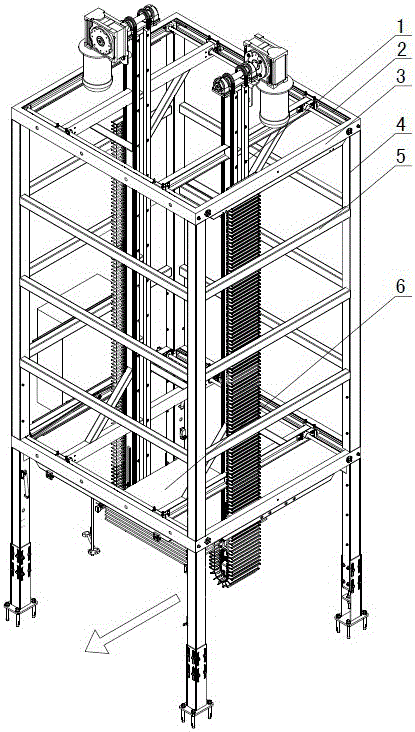

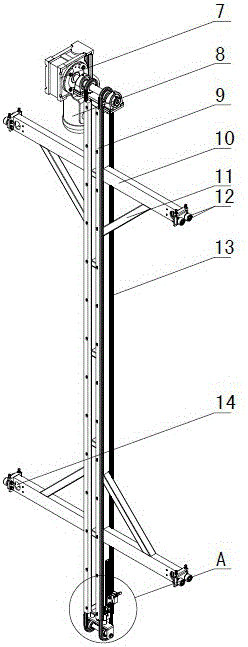

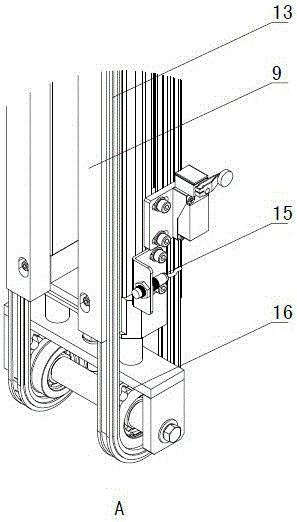

[0048] Figure 1~8 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~8 The present invention will be further described.

[0049] A ceramic tile packaging assembly line tile temporary brick storehouse, comprising a main frame of the brick storehouse, a set of tile lifting devices 1 installed inside the main frame of the brick storehouse, and a width adjusting device for adjusting the distance between the tile lifting devices 1 . figure 1 The middle arrow shows the moving direction of the tile 6. In the tile temporary storage warehouse (hereinafter referred to as the storage brick warehouse) of the ceramic tile packaging line, the position of the tile 6 storage is set as the rear of the storage brick warehouse, and the tile 6 is out of the warehouse. The position of is set to the place ahead of this brick storehouse.

[0050] Such as figure 1 As shown, the main frame of the brick storage silo is a rectangular body, and a two-sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com