Sampling method and analyzing method for oxygen and nitrogen analysis samples

A technology for analyzing samples and analysis methods, which is applied in the field of sample preparation for oxygen and nitrogen analysis samples, and can solve problems affecting the accuracy of oxygen element analysis in steel, freezing liquid and oil pollution, and difficulty in sample preparation, etc., achieving advantages and disadvantages The judgment is intuitive, the preparation is convenient, and the effect of meeting the online inspection and guiding production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

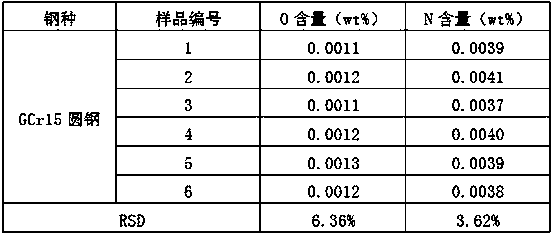

[0020] Embodiment 1: The specific process of the sample preparation method and analysis method of the oxygen and nitrogen analysis sample is as follows.

[0021] Detect oxygen and nitrogen elements in φ35mm, GCr15 round steel. Use a metallographic cutting machine to cut off the end of the sample, and then cut it into 6 discs with a thickness of 2±0.5mm. Use a hand-held grinding tool for rough grinding on a 60-mesh abrasive belt, and then on a 120-mesh fine sandpaper. Finishing and grinding, surface roughness Ra<1.6μm (referring to the average convex and concave depth of the sample surface); finally use a punching machine to punch the sheet sample into a round cake-shaped analysis sample, with a thickness of 2±0.5mm and a weight of 0.5~1.0g (Punched samples have the same diameter, different thickness, and different quality). The analysis samples were soaked in acetone and ultrasonically cleaned for 5 minutes, dried with a hair dryer and weighed.

[0022] The analysis conditio...

Embodiment 2

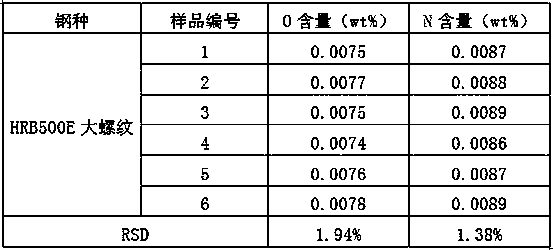

[0025] Embodiment 2: The specific process of the sample preparation method and analysis method of the oxygen and nitrogen analysis sample is as follows.

[0026] Detect oxygen and nitrogen elements in φ32mm, HRB500E large thread. Use a metallographic cutting machine to cut off the end of the sample, and then cut it into 6 discs with a thickness of 2±0.5mm. Use a hand-held grinding tool to perform rough grinding on a 40-mesh abrasive belt, and then on a 180-mesh fine sandpaper. Finishing and grinding, the surface finish Ra<1.6μm; finally, use a punching machine to punch the flake-shaped sample into a round cake-shaped analysis sample, with a thickness of 2±0.5mm and a weight of 0.5-1.0g. The analysis samples were soaked in absolute ethanol, cleaned ultrasonically for 8 minutes, and dried with a hair dryer until the ethanol was completely volatilized, and weighed.

[0027] The same analysis conditions as in Example 1 were adopted (consistent equipment working conditions). Make...

Embodiment 3

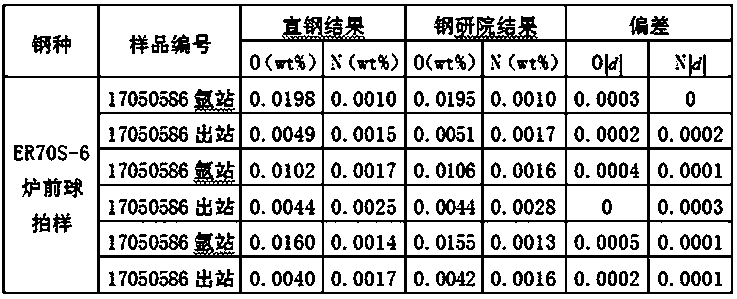

[0030] Embodiment 3: The specific process of the sample preparation method and analysis method of the oxygen and nitrogen analysis sample is as follows.

[0031] Detect the oxygen and nitrogen content in the φ20mm, ER70S-6 racket sample before the furnace. First, remove the tail peduncle with a tail peduncle cutter, and remove 2 to 3 mm of oxide skin before slicing. Cut a sheet sample with a thickness of 10mm, and can slice 2 to 3 pieces. Use a hand-held grinding tool to perform rough grinding on a 50-mesh abrasive belt, and then finish grinding on a 180-mesh fine sandpaper, with a surface finish of Ra<1.6 μm; finally use a punching machine to punch the sheet sample into a round cake Analysis sample, thickness 2±0.5mm, weight 0.5~1.0g. Vacuum sampler is used for the analysis sample of the racket in front of the furnace. It is inevitable that there will be air holes or inclusions during the sampling process. When punching samples, the air holes or the positions of inclusions ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com