Curing agent production system based on air-jet disturbance

A production system and curing agent technology, applied in the direction of loading/unloading, containers, packaging, etc., can solve problems such as ventilation pipe blockage, achieve the effect of increasing sealing, preventing loosening, and ensuring fast transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

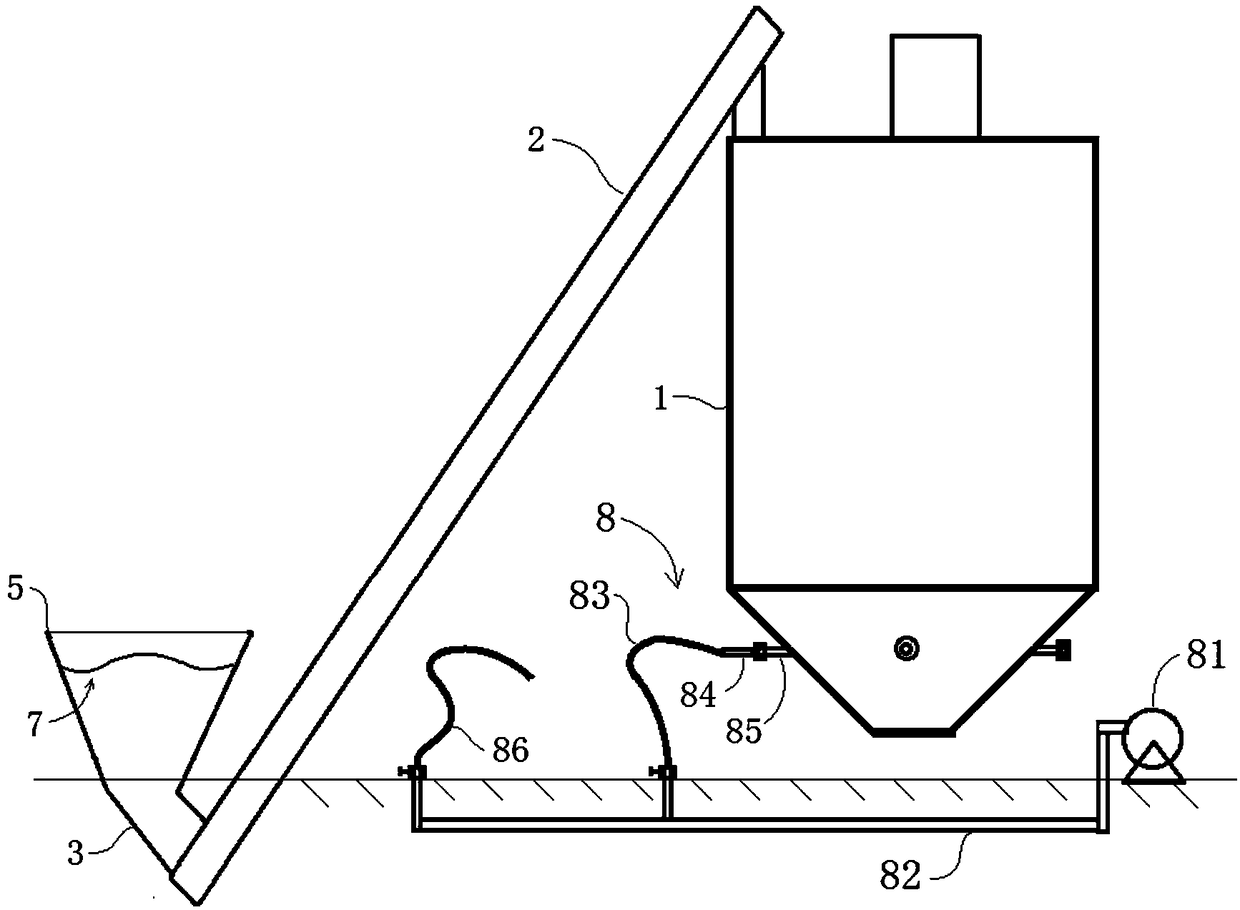

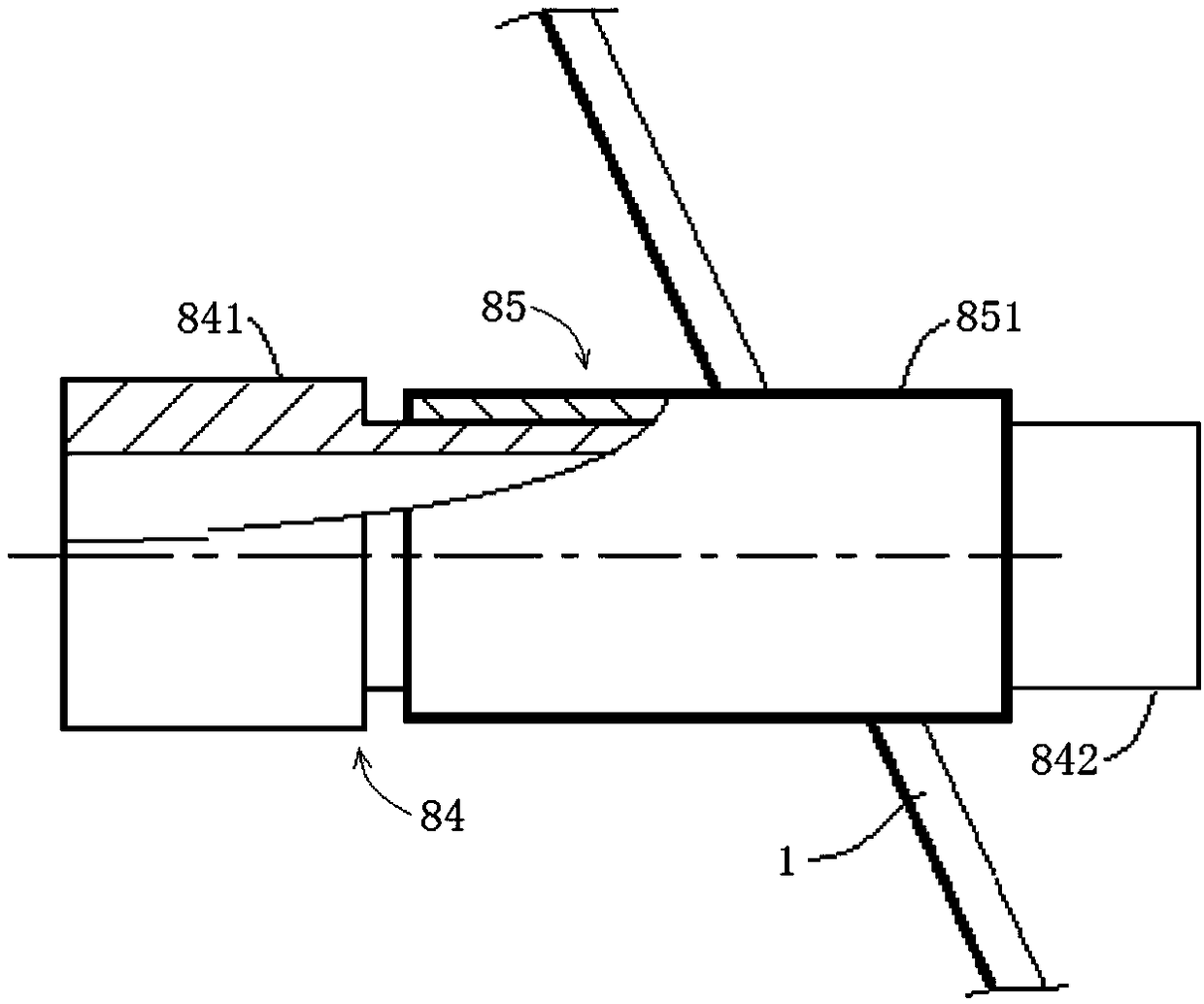

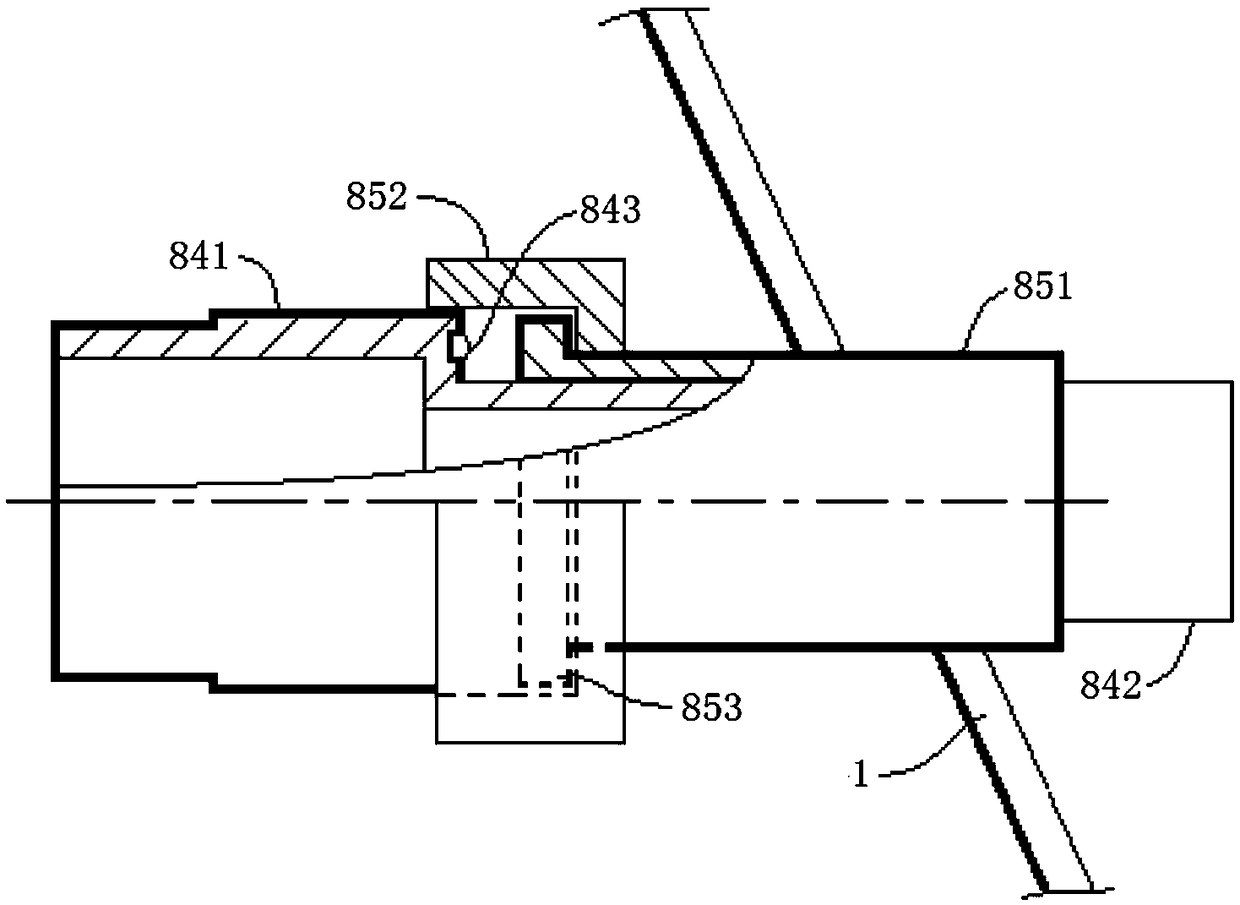

[0037] combine figure 1 , a curing agent production system based on air jet disturbance in this embodiment includes a material tank 1, a screw feed pipe 2 and a hopper 5. In order to facilitate operation, a ground trough is arranged on the ground of the platform installation area, and the lower end of the hopper 5 is embedded If the ground trough is used, after workers clean up the floor of the workshop, they can directly pour the cleaned powder into the hopper 5 without using other equipment for transportation and other operations. Since there are mostly scattered powders in the workshop and there are few external sundries, these powders can be recycled, so that the bottom of the hopper 5 is connected to one end of the screw feeding pipe 2 through the connecting sleeve 3, and the other end of the screw feeding pipe 2 One end leads to the material tank 1, and the powder in the hopper 5 can be transported to the material tank 1. The inside of the screw feeding pipe 2 is a scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com