Marble plate production line with marble plate profile tapping machine

A marble slab, marble slab technology, applied in stone processing equipment, stone processing tools, layered products, etc., can solve the problems of belt punching, low hole forming efficiency, hand hammer injury, etc., and achieve reasonable process layout and production. The effect of high efficiency and good market promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

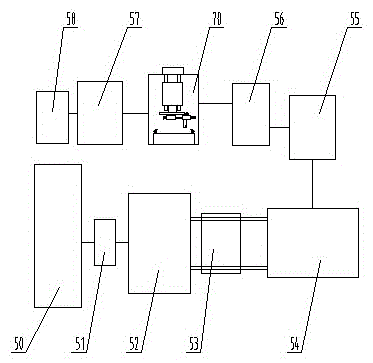

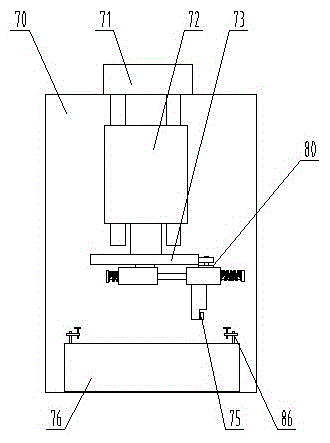

[0008] Such as figure 1 , 2 As shown, the present invention includes a marble rough mining system 50, a transportation system 51 for transporting marble rough to the processing plant area, a marble rough lifting frame saw 52, a slab track transfer vehicle 53, and an automatic bonding line 54 for marble slab back stickers , marble slab polishing and grinding machine 55, marble slab preliminary cutting machine 56, marble slab profiling hole opening machine, marble slab precision cutting machine 57 and marble slab edge grinding machine 58, transportation system 51 is used to mine marble rough stone mining system 50 The rough marble is transported to the processing plant area, the loading end of the marble rough lifting frame saw 52 is located at the discharging end of the transportation system 51, and the loading end of the plate track transfer vehicle 53 is located at the discharging end of the marble rough lifting frame saw 52 At the position, the feeding end of the conveyor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com