Device and process for purifying brine

A purification device and a technology for brine solution, which are applied in alkali metal halide purification, chemical instruments and methods, loose filter material filters, etc., can solve the problems of poor quality brine solution, high cost, volume restriction, etc. Achieve the effect of large capacity for processing brine, reasonable process layout and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below, with reference to accompanying drawing and embodiment device of the present invention and technology thereof are described in detail:

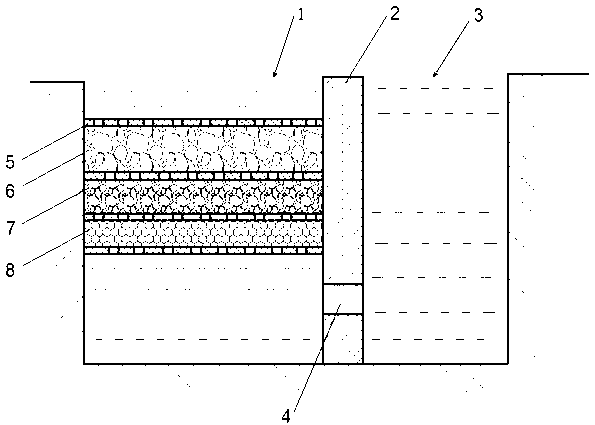

[0030] Such as figure 1 As shown, a brine purification device includes a dissolution tank 1, a tank separation plate 2, a liquid storage tank 3, a diversion hole 4, a partition 5, a primary filter layer 6, a middle filter layer 7 and a fine filter layer 8. The sub-tank plate 2 separates the purification device into a dissolution tank 1 and a liquid storage tank 3. In the dissolution tank 1, four partitions 5 are used to divide it into three parts: the primary filter layer 6, the middle filter layer 7 and the fine filter layer 8 from top to bottom. .

[0031] A flow guide hole 4 is formed on the lower part of the slotted plate 2 , and a plurality of small holes are formed on the partition plate 5 .

[0032] Among them: the primary filter layer 6 is made of coarse sand and gravel, and the thickness of the filter layer is 20m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com