A multi-layer wear-resistant carbon fiber continuous sucker rod and its preparation device and preparation method

A carbon fiber and sucker rod technology, applied in lamination devices, chemical instruments and methods, lamination and other directions, can solve the problems of poor torsional strength of carbon fiber sucker rods, adverse effects of sucker rod strength, poor wear resistance, etc. Achieve the effect of improving efficiency, light weight and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

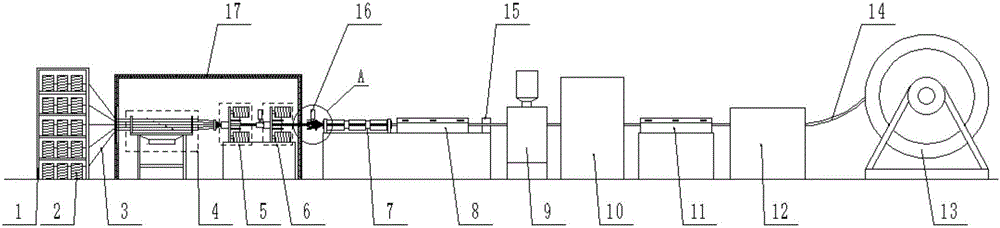

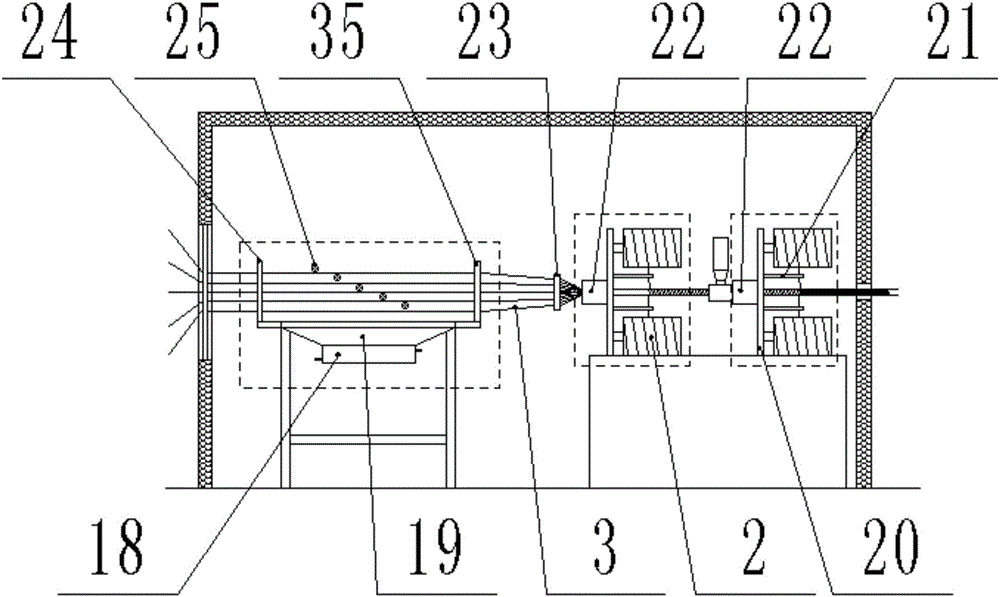

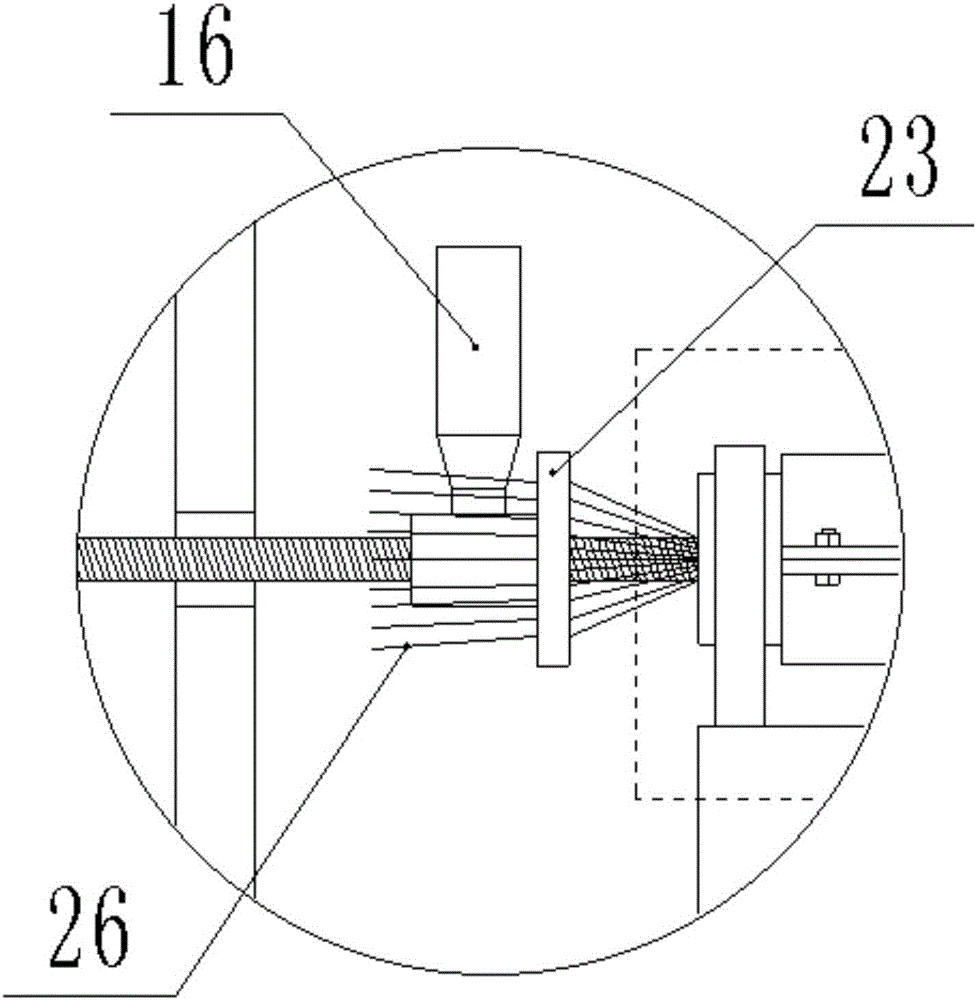

[0038] A multi-layer wear-resistant carbon fiber continuous sucker rod, including a carbon fiber core 28, the carbon fiber core 28 is composed of 150 / 12K---242 / 12K carbon fiber bundles bonded by epoxy resin, and the carbon fiber is stretched Strength ≥ 4950MPa, the carbon fiber core 28 is spirally wound with a wound glass fiber layer A29 and a wound glass fiber layer B34 in turn, the wound glass fiber layer B34 is covered with a longitudinal glass fiber layer 30, and the outer wall of the longitudinal glass fiber layer 30 is coated with Covered with epoxy resin layer 31 . Winding glass fibers can bind each strand of carbon fiber in the carbon fiber core 28, avoiding the separation of each strand of carbon fiber when the sucker rod is subjected to torque and causing damage to the sucker rod, thereby effectively enhancing the torsional strength of the sucker rod. Wrapping the carbon fiber core 28 can effectively prevent the longitudinal glass fiber layer 30 from blending with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com