Continuous sucker rod with communication function and preparation device and preparation method thereof

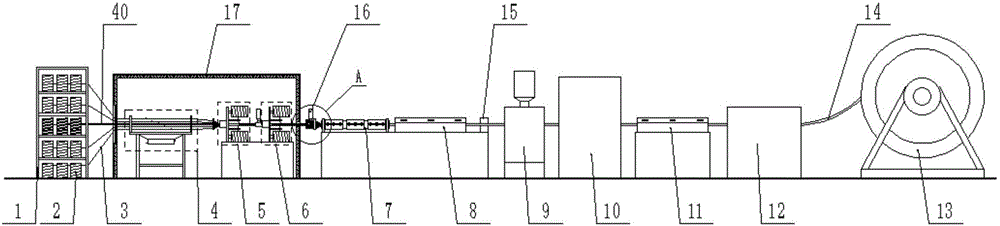

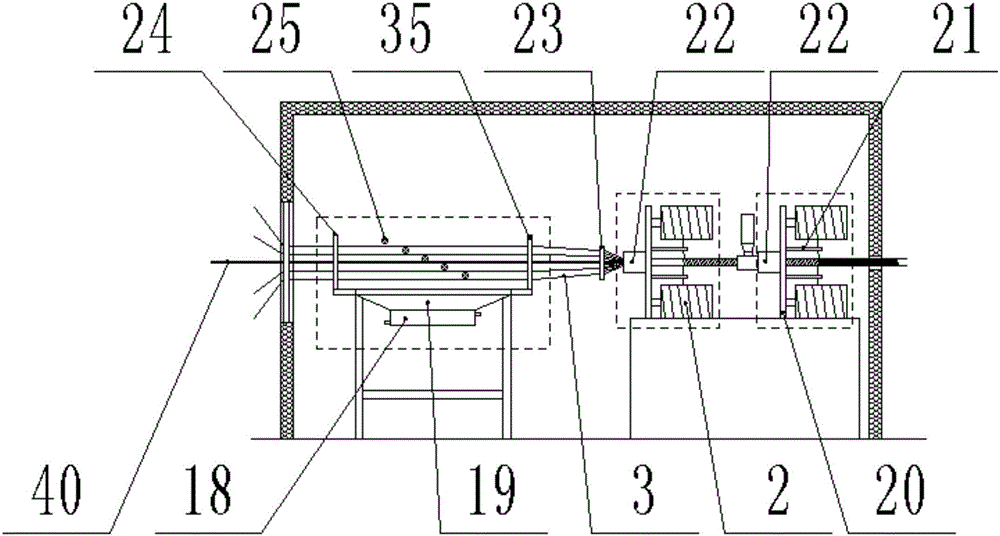

A technology of communication function and sucker rod, which is applied in the direction of drill pipe, drilling equipment, earthwork drilling and production, etc. It can solve the problems of complex construction process, poor wear resistance, poor torsional strength, etc., and achieve reasonable process layout and simple process operation , high tensile strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

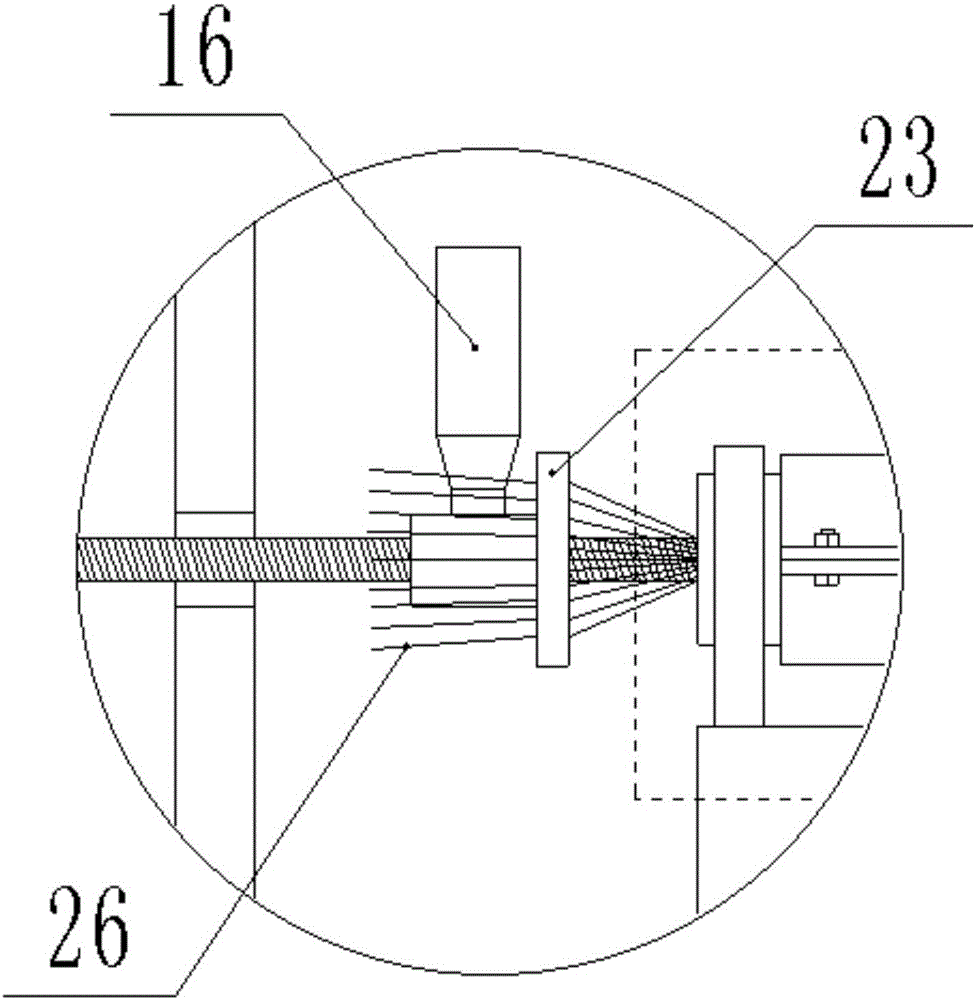

[0044] A continuous sucker rod with communication function, comprising a carbon fiber core 28, the center of the carbon fiber core 28 is provided with an electric heating belt 40, and the setting of the heating belt 40 can realize constant temperature heating of the sucker rod, even if The sucker rod maintains a high and stable temperature to prevent the paraffin in the crude oil from condensing on the sucker rod.

[0045] An optical fiber 45 is wound around the electric heating band 40 (the optical fiber 45 needs to be provided with an insulating and waterproof protective layer), and the carbon fiber constituting the carbon fiber core 28 is wrapped around the electric heating band 40 and the optical fiber 45 . The arrangement of the optical fiber 45 can provide a data transmission medium for the communication between the ground and the downhole, and there is no need to pull out the sucker rod during operation, so it has the characteristics of simple construction process and st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com