Die pressing automatic molding system for interior trim plate of car roof and process of die pressing automatic molding system

An automatic forming and automobile roof technology, which is applied to the automatic molding system of automobile ceiling interior panel molding and its technology field, can solve the problems of high labor intensity of workers, low product qualification rate, inaccurate positioning of hemp boards, etc., and can reduce the softening time. , The effect of accurate mobile positioning and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

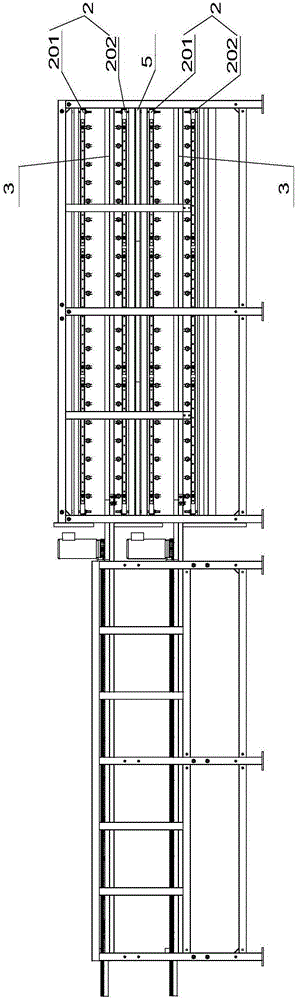

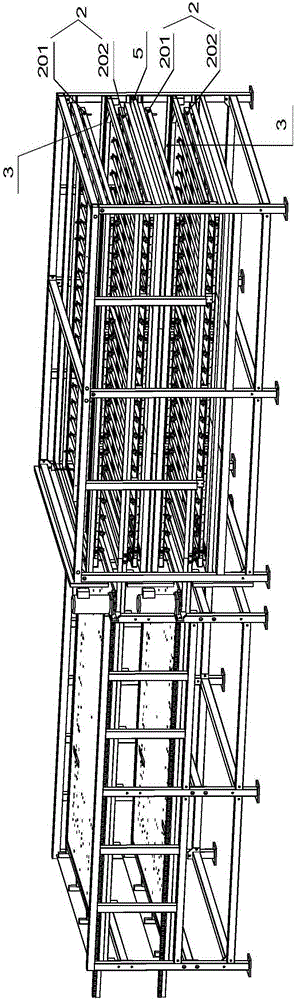

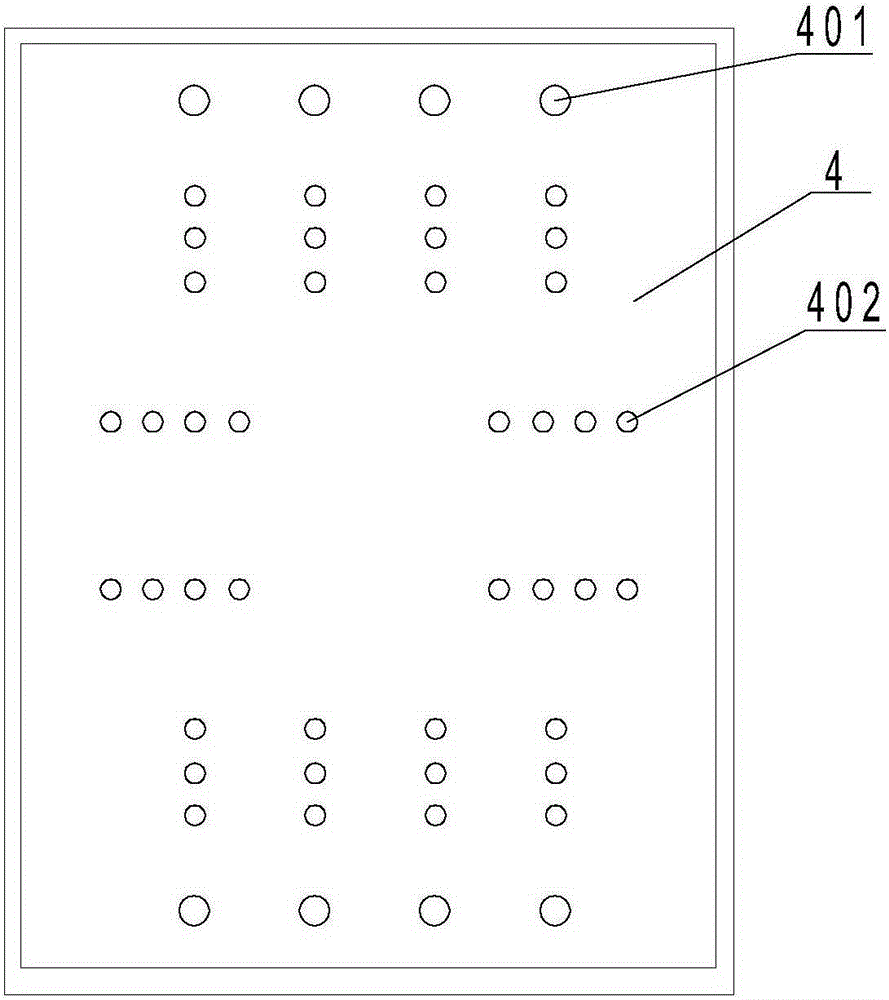

[0040] An automatic molding system for automotive ceiling interior trim panel molding, including a pressing mold, a press, automatic fabric cutting equipment, a robot, and an oven. The oven includes a box frame 1, a heating device 2, a rail 3 located in the heating device 2, A flat shovel 4 placed on the track 3 for placing the substrate; among them:

[0041] There are two sets of heating devices 2 which are respectively installed in parallel on the rack 1 of the oven. A heat shield 5 is arranged between the two heating devices 1; each heating device 2 includes an upper heating plate 201 and The lower heating plate 202, a plurality of heating elements 203-infrared intermediate frequency heating tubes, are respectively installed on the upper and lower heating plates;

[0042] The track 3 is installed on the box frame between the upper and lower heating plates of each heating device 2, and both ends of the track 3 are respectively installed with stoppers to limit the front and rear p...

Embodiment 2

[0046] A molding process for auto roof interior trim panels, the process including the following steps:

[0047] S1. Fabric preparation:

[0048] The fabric rolls are placed in the automatic fabric cutting equipment according to the production specifications, and are automatically cut to a fixed length according to the designed length by the automatic fabric cutting equipment;

[0049] S2. Substrate preparation:

[0050] The base material is prepared according to the designated flat shovel and installed in the flat shovel;

[0051] S3. Substrate heating:

[0052] The robot automatically places the flat shovel with the substrate on the guide rail of the oven through the manipulator for oven heating, the heating temperature is 220 ℃, and the heating time is 95 seconds;

[0053] S4. Take out the fabric: While the substrate is heated, the robot takes the cut fabric through the manipulator, and places the pre-cut fabric in the substrate baking area for waiting;

[0054] S5. Take the substrate: ...

Embodiment 3

[0060] An automatic molding process for auto roof interior trim panel molding. The steps of the process are basically the same as those of the second embodiment. The difference is that the process parameters are different. In the step S3, the heating temperature is 250°C and the heating time is 110 seconds; the pressure in step S6 is controlled at 15 MPa; the pressure holding in step S7 is 30 seconds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com