Pollution-free isooctane regeneration production line

A production line, isooctane technology, applied in the field of pollution-free isooctane regeneration production line, to achieve the effect of reasonable process layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

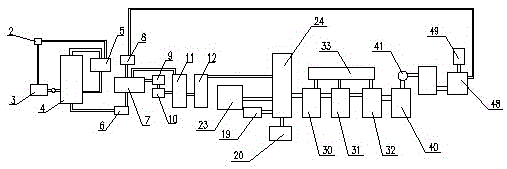

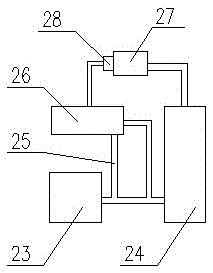

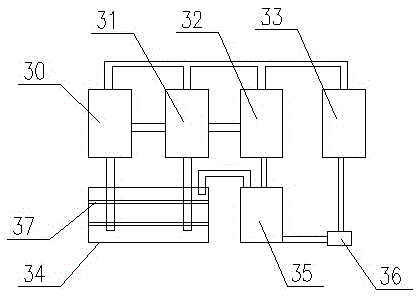

[0011] like figure 1 , 2 , 3, 4, and 5, the present invention includes refrigerant pump 2, raw material buffer tank 3, depropanizer 4, depropanizer top reflux tank 5, dehydrator 6, reactor 7, sulfuric acid settler 8, pickling Settling chamber 9, alkali washing settling chamber 10, de-isobutanizer 11, de-n-butanizer 12 and sulfuric acid regeneration production line, refrigerant pump 2 communicates with raw material buffer tank 3 and depropanizer top reflux tank 5 respectively, raw material buffer The outlet of the tank 3 communicates with the inlet of the depropanizer 4 through a pump, the outlet of the depropanizer 4 communicates with the inlet of the dehydrator 6, and the depropanizer top reflux tank 5 also communicates with the depropanizer 4 through a pipeline, and the reactor 7 There are respectively raw material inlet and outlet, catalyst inlet and auxiliary material inlet, the outlet of dehydrator 6 communicates with the raw material inlet of reactor 7, the outlet of su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com