Plate production process and production line thereof

A sheet metal production and production line technology, applied in manufacturing tools, ceramic molding workshops, ceramic molding machines, etc., can solve the problems of unreasonable process layout, large plant area, low production efficiency, etc., to improve maintenance efficiency and reduce investment costs. , the effect of reducing the floor area of the plant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

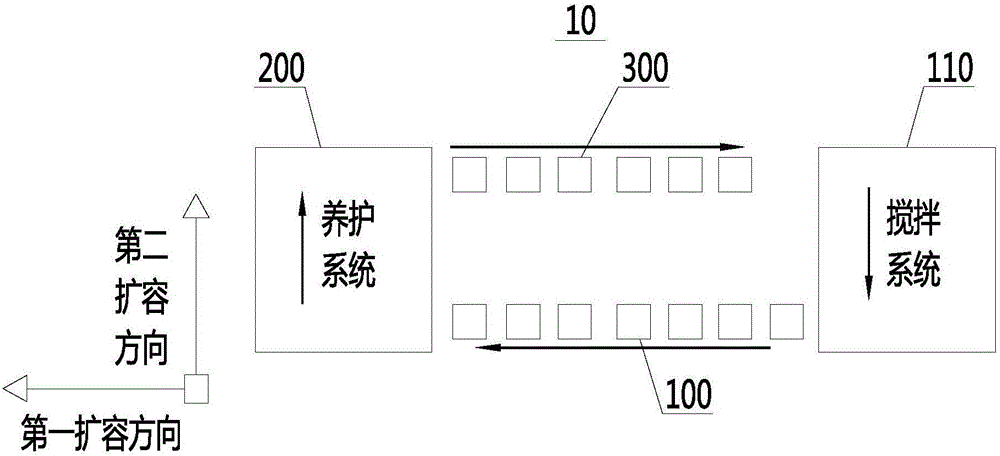

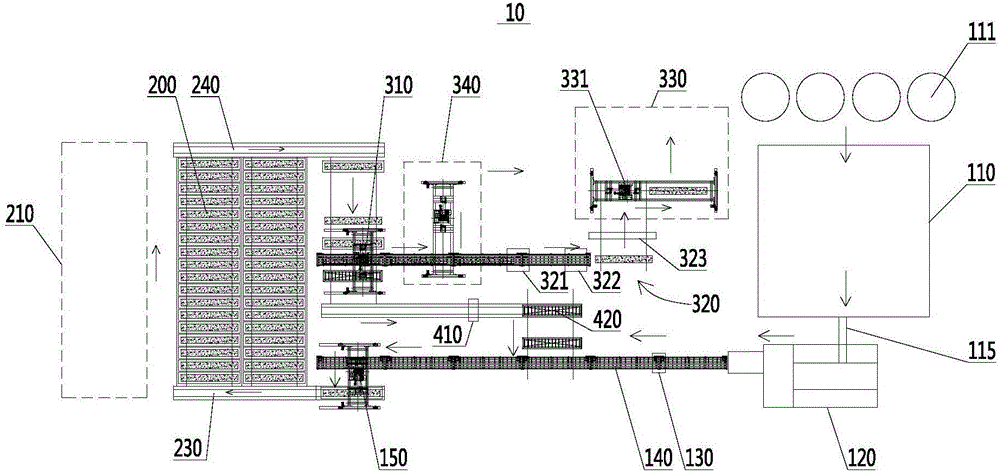

[0033] see figure 1 , the present embodiment provides a plate production line 10, which includes a pre-curing processing device 100, a curing system 200, and a post-curing processing device 300 connected in sequence.

[0034] The maintenance system 200 is located at one end of the plate production line 10 . The processing equipment 100 before maintenance and the processing equipment 300 after maintenance are located on the same side of the maintenance system 200 . Preferably, the processing equipment before maintenance 100 and the processing equipment after maintenance 300 are arranged in a substantially straight line, and more preferably, the straight lines where the processing equipment before maintenance 100 and the processing equipment 300 after maintenance are parallel to each other.

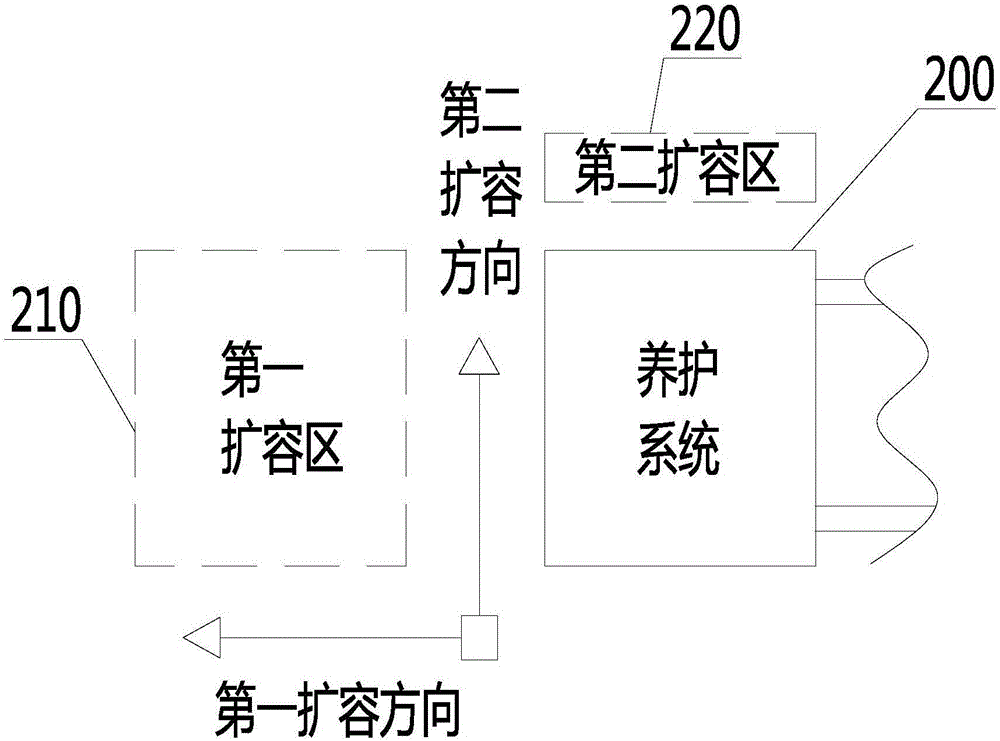

[0035] Please refer to figure 1 and figure 2 , in this embodiment, the maintenance system 200 can be infinitely expanded along the first expansion direction and / or the second expansion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com