Subway dedicated shield tunneling segment prefabricated construction method

A shield segment and subway technology, applied in underground chambers, shaft linings, tunnel linings, etc., can solve the problems of low turnover efficiency of segment molds and insufficient production speed, and achieve standardized product quality acceptance standards and production efficiency High and productive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

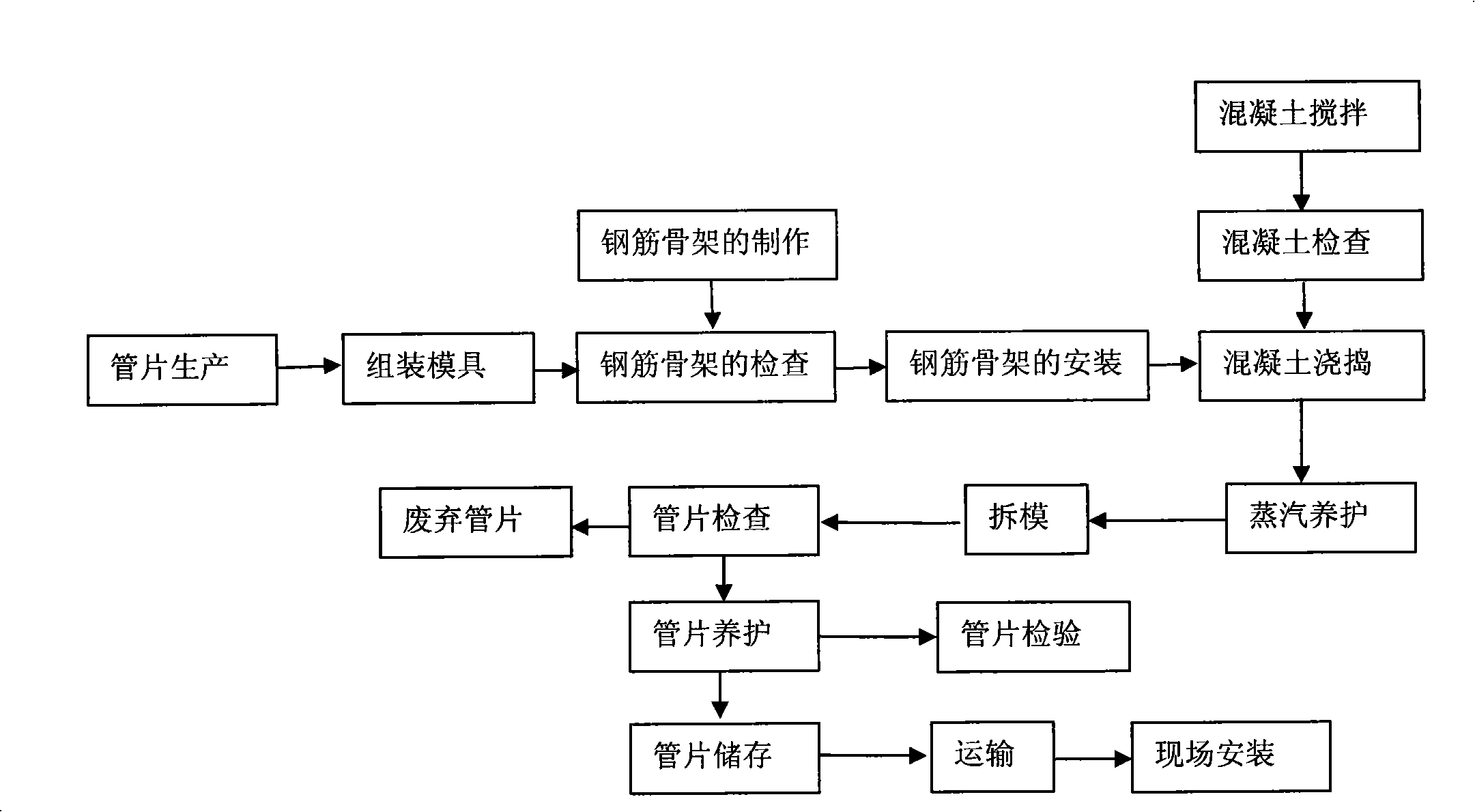

Image

Examples

Embodiment Construction

[0023] First, the production of steel skeleton

[0024] Fabrication and inspection of the steel skeleton: the fabrication of the steel skeleton is carried out in the steel workshop. 2 The arc welding machine performs welding and forming on the fixed-length mold, and then puts the prepared steel skeleton into the standard master form for inspection. After passing the inspection, the steel skeleton is transported from the steel workshop to the segment forming workshop by a forklift.

[0025] 1 The operation should be carried out according to the large-scale drawing of steel bar processing issued by the design engineer, and if there is any change, it should be carried out according to the change notice. The length measurement method and bending size measurement method of the specific shape of the steel bar shall meet the requirements of the drawings.

[0026] 2 Rebar cutting workers should cut and process the steel bars according to the work sheet issued by the foreman of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com