Linear liquid injection machine for capacitance battery and liquid injection method thereof

A capacitive battery, linear technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problem that the injection volume cannot be found online and replenished in time, the short-circuited battery cannot be picked out in time, and the injection port scrubbing process can be added. and other problems, to achieve the effect of eliminating complicated operations, concise design, reducing labor intensity and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

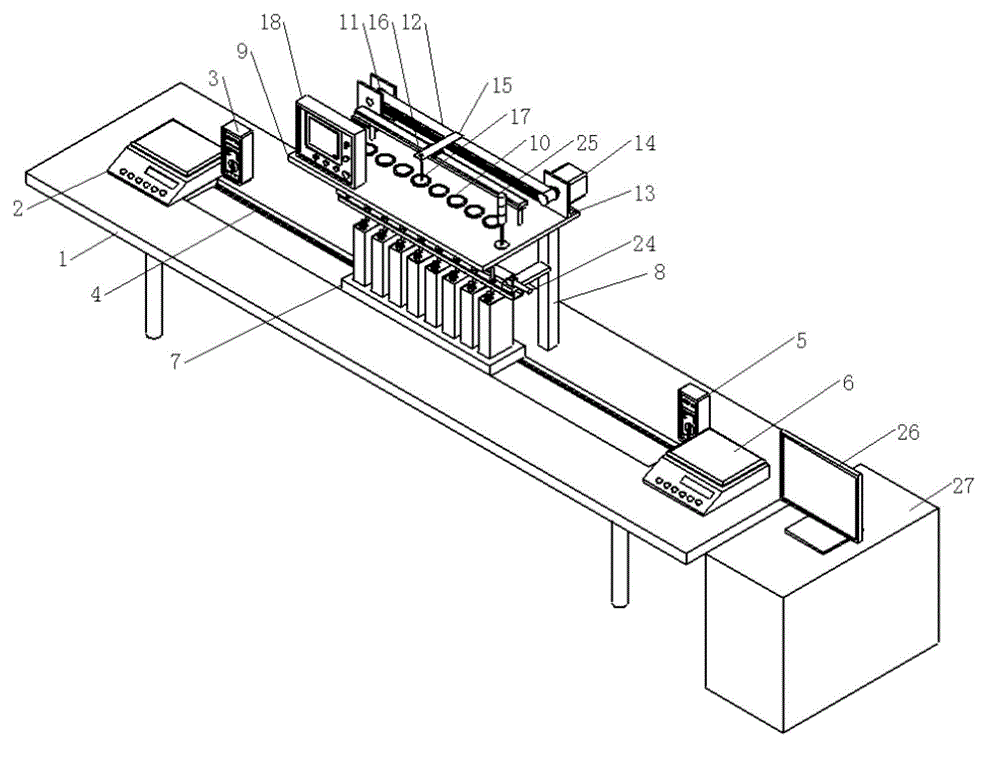

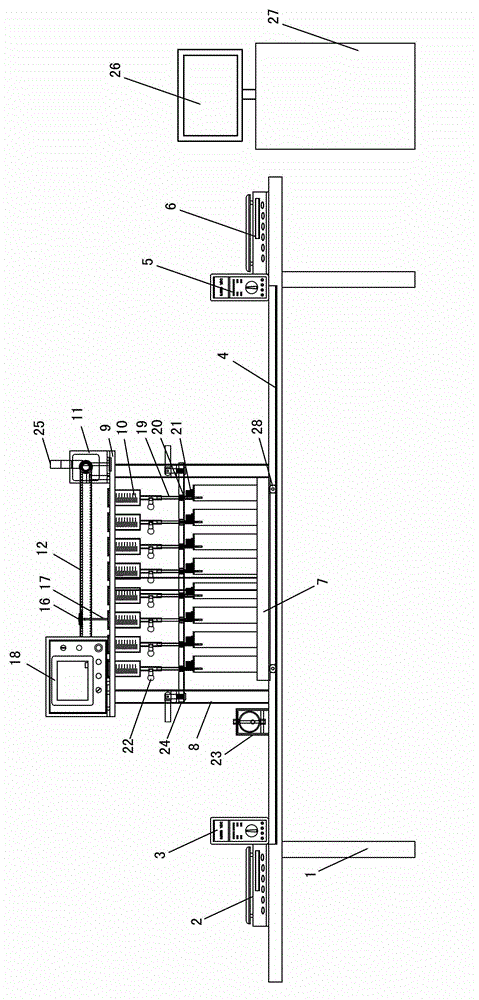

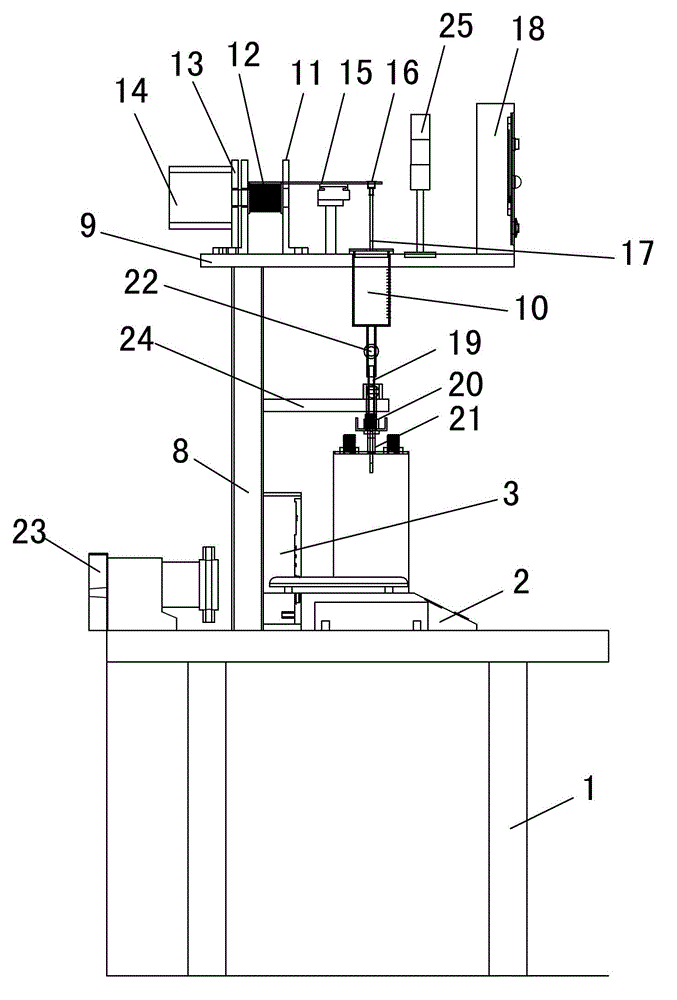

[0035] Such as Figure 1~3 As shown, the linear liquid injection machine for capacitor batteries includes a frame 1, on which a front weighing device 2, a front voltage measuring device 3, a linear guide rail 4, a rear voltage measuring device 5 and a rear weighing device 6 are sequentially arranged. , the frame 1 on one side of the linear guide rail 4 is equipped with a normal pressure liquid injection device, and the linear guide rail 4 is provided with a tray 7 .

[0036] The normal pressure liquid injection device includes a frame body 8, a bracket plate 9 is arranged on the top of the frame body 8, and the bracket plate 9 is located above the linear guide rail 4. Eight liquid injection barrels 10 are arranged side by side, and the liquid injection barrels 10 are marked with scales. , the rear end of support plate 9 is equipped with conveyor belt frame 11, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com